What is Global Polyaspartic Concrete Floor Coatings Market?

The Global Polyaspartic Concrete Floor Coatings Market is a specialized segment within the broader coatings industry, focusing on the application of polyaspartic coatings to concrete floors. These coatings are known for their rapid curing times, high durability, and resistance to various environmental factors, making them an attractive option for both residential and commercial applications. Polyaspartic coatings are a type of polyurea, which is a subgroup of polyurethane, and they offer several advantages over traditional epoxy coatings, such as faster application times and greater flexibility. The market for these coatings is driven by the growing demand for durable and aesthetically pleasing flooring solutions in various sectors, including industrial, commercial, and residential buildings. As urbanization and industrialization continue to rise globally, the need for efficient and long-lasting flooring solutions becomes more pronounced, thereby boosting the demand for polyaspartic concrete floor coatings. Additionally, the increasing awareness of the benefits of these coatings, such as their UV stability and chemical resistance, further propels their adoption across different regions. The market is characterized by a diverse range of products and applications, catering to the specific needs of different end-users.

Fast Setting Polyaspartic Concrete Floor Coatings, Slow Setting Polyaspartic Concrete Floor Coatings in the Global Polyaspartic Concrete Floor Coatings Market:

Fast Setting Polyaspartic Concrete Floor Coatings are designed for projects that require quick turnaround times. These coatings cure rapidly, often within a few hours, allowing for minimal downtime and quick resumption of activities in the coated area. This makes them ideal for commercial and industrial settings where time is of the essence, such as warehouses, factories, and retail spaces. The fast-setting nature of these coatings does not compromise their durability or performance. They offer excellent abrasion resistance, chemical resistance, and UV stability, ensuring that the floor remains in good condition even under heavy use. The application process for fast-setting polyaspartic coatings is relatively straightforward, but it requires skilled professionals to ensure a smooth and even finish. These coatings can be applied in a wide range of temperatures, making them suitable for various climates and environments. On the other hand, Slow Setting Polyaspartic Concrete Floor Coatings are designed for projects where time is not a critical factor. These coatings take longer to cure, allowing for more intricate application processes and the incorporation of decorative elements such as flakes or pigments. Slow-setting coatings are often used in residential settings where aesthetics are a priority, such as in living rooms, kitchens, and garages. They provide the same level of durability and resistance as their fast-setting counterparts but offer more flexibility in terms of design and customization. The slower curing time allows for more detailed work, making them ideal for projects that require a high level of craftsmanship. Both fast and slow-setting polyaspartic coatings offer significant advantages over traditional flooring solutions, such as epoxy or polyurethane coatings. They are more resistant to yellowing and fading, making them suitable for areas exposed to sunlight. Additionally, they have a lower VOC content, making them more environmentally friendly and safer for indoor use. The choice between fast and slow-setting coatings depends on the specific needs of the project, including the desired appearance, the time available for application, and the environmental conditions of the site. In the Global Polyaspartic Concrete Floor Coatings Market, both types of coatings have their place, catering to different segments and applications. The versatility and performance of polyaspartic coatings make them a popular choice for a wide range of flooring projects, from industrial warehouses to residential homes. As the market continues to grow, innovations in formulation and application techniques are expected to further enhance the capabilities and appeal of these coatings.

Residential Building, Non-Residential Building in the Global Polyaspartic Concrete Floor Coatings Market:

The usage of Global Polyaspartic Concrete Floor Coatings Market in residential buildings is primarily driven by the need for durable, aesthetically pleasing, and low-maintenance flooring solutions. Homeowners are increasingly opting for polyaspartic coatings in areas such as garages, basements, and patios due to their excellent resistance to stains, chemicals, and abrasions. These coatings provide a seamless and glossy finish that enhances the overall appearance of the space while offering long-lasting protection against wear and tear. In addition to their functional benefits, polyaspartic coatings are available in a variety of colors and finishes, allowing homeowners to customize their floors to match their personal style and home decor. The quick curing time of these coatings is another advantage, as it minimizes disruption to daily life during the installation process. In non-residential buildings, the demand for polyaspartic concrete floor coatings is driven by the need for robust and resilient flooring solutions that can withstand heavy foot traffic, machinery, and harsh environmental conditions. These coatings are commonly used in commercial spaces such as retail stores, restaurants, and office buildings, where aesthetics and durability are equally important. The ability of polyaspartic coatings to resist UV rays and maintain their color and gloss over time makes them an ideal choice for areas with high exposure to sunlight. In industrial settings, such as factories and warehouses, polyaspartic coatings provide a tough and durable surface that can withstand the rigors of heavy equipment and chemical spills. The fast curing time of these coatings is particularly beneficial in non-residential applications, as it allows for quick installation and minimal downtime, ensuring that business operations can resume promptly. Furthermore, the low VOC content of polyaspartic coatings makes them an environmentally friendly option, aligning with the growing trend towards sustainable building practices. Overall, the versatility and performance of polyaspartic concrete floor coatings make them a valuable asset in both residential and non-residential buildings, offering a combination of aesthetic appeal, durability, and environmental benefits.

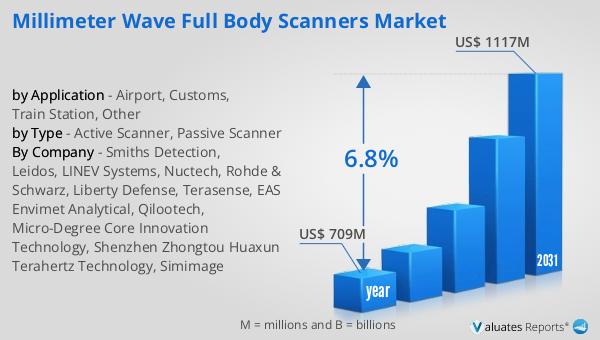

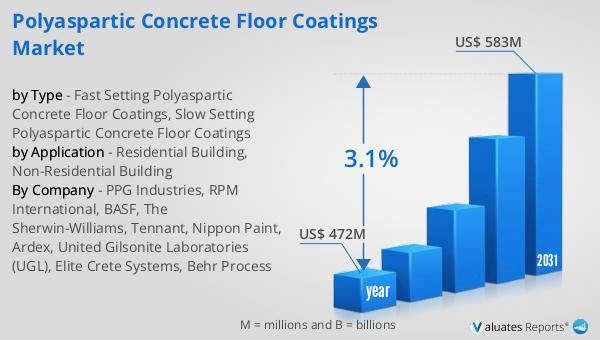

Global Polyaspartic Concrete Floor Coatings Market Outlook:

The global market for Polyaspartic Concrete Floor Coatings was valued at $472 million in 2024, and it is anticipated to grow to a revised size of $583 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% over the forecast period. This growth trajectory underscores the increasing demand for polyaspartic coatings across various sectors, driven by their superior performance characteristics and versatility. The market's expansion is fueled by the rising need for durable and aesthetically pleasing flooring solutions in both residential and commercial settings. As urbanization and industrialization continue to accelerate, the demand for efficient and long-lasting flooring solutions becomes more pronounced, further propelling the adoption of polyaspartic concrete floor coatings. The market is characterized by a diverse range of products and applications, catering to the specific needs of different end-users. The increasing awareness of the benefits of these coatings, such as their UV stability, chemical resistance, and quick curing times, further drives their adoption across different regions. As the market continues to grow, innovations in formulation and application techniques are expected to enhance the capabilities and appeal of these coatings, solidifying their position as a preferred choice for flooring solutions worldwide.

| Report Metric | Details |

| Report Name | Polyaspartic Concrete Floor Coatings Market |

| Accounted market size in year | US$ 472 million |

| Forecasted market size in 2031 | US$ 583 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PPG Industries, RPM International, BASF, The Sherwin-Williams, Tennant, Nippon Paint, Ardex, United Gilsonite Laboratories (UGL), Elite Crete Systems, Behr Process |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |