What is Global Photovoltaic Packaging EVA Film Market?

The Global Photovoltaic Packaging EVA Film Market is a crucial segment within the renewable energy industry, primarily focusing on the encapsulation of solar cells. Ethylene Vinyl Acetate (EVA) films are used extensively in the photovoltaic (PV) industry due to their excellent adhesive properties, durability, and ability to withstand harsh environmental conditions. These films serve as a protective layer for solar cells, ensuring their longevity and efficiency by safeguarding them from moisture, dust, and mechanical damage. The market for these films is driven by the increasing demand for solar energy as a sustainable and clean energy source. As countries worldwide strive to reduce their carbon footprint and transition to renewable energy, the demand for efficient and reliable solar modules is on the rise. EVA films play a pivotal role in this transition by enhancing the performance and lifespan of solar panels. The market is characterized by continuous innovation and technological advancements aimed at improving the efficiency and cost-effectiveness of EVA films. Manufacturers are investing in research and development to produce films with better thermal stability, UV resistance, and optical properties. This market is expected to grow significantly as the global push towards renewable energy intensifies, making EVA films an indispensable component of the solar energy industry.

Ordinary EVA Adhesive Film, Functional EVA Adhesive Film in the Global Photovoltaic Packaging EVA Film Market:

Ordinary EVA Adhesive Film and Functional EVA Adhesive Film are two primary types of films used in the Global Photovoltaic Packaging EVA Film Market, each serving distinct purposes and offering unique benefits. Ordinary EVA Adhesive Film is widely used in the encapsulation of solar cells due to its excellent adhesive properties, transparency, and flexibility. It provides a protective layer that shields the solar cells from environmental factors such as moisture, dust, and mechanical stress, thereby enhancing the durability and efficiency of solar panels. This type of film is cost-effective and easy to process, making it a popular choice among manufacturers. It is particularly suitable for standard solar modules where basic protection and performance are required. On the other hand, Functional EVA Adhesive Film is designed to offer enhanced performance characteristics, catering to the evolving needs of the solar industry. These films are engineered to provide superior thermal stability, UV resistance, and optical properties, making them ideal for high-performance solar modules. Functional EVA films are often used in advanced applications where higher efficiency and longer lifespan of solar panels are critical. They are particularly beneficial in regions with extreme weather conditions, as they offer better protection against temperature fluctuations and UV radiation. The development of Functional EVA films is driven by the increasing demand for more efficient and durable solar panels, as well as the need to reduce the overall cost of solar energy systems. Manufacturers are focusing on innovation and technological advancements to produce films that can enhance the performance of solar modules while maintaining cost-effectiveness. This includes the development of films with improved light transmission, reduced degradation rates, and enhanced mechanical properties. The choice between Ordinary and Functional EVA Adhesive Films depends on various factors, including the specific requirements of the solar module, the environmental conditions in which the panels will be deployed, and the cost considerations of the project. While Ordinary EVA films are suitable for standard applications, Functional EVA films are preferred for high-performance and specialized applications where enhanced protection and efficiency are required. As the solar industry continues to grow and evolve, the demand for both Ordinary and Functional EVA Adhesive Films is expected to increase, driven by the need for more efficient, durable, and cost-effective solar energy solutions. The ongoing research and development efforts in this field are likely to result in the introduction of new and improved EVA films that can further enhance the performance and longevity of solar panels, contributing to the overall growth of the Global Photovoltaic Packaging EVA Film Market.

Monofacial Module, Bifacial Module in the Global Photovoltaic Packaging EVA Film Market:

The usage of Global Photovoltaic Packaging EVA Film Market in Monofacial and Bifacial Modules highlights the versatility and importance of EVA films in the solar industry. Monofacial Modules, which are the traditional type of solar panels, have solar cells on one side only. These modules rely on EVA films to encapsulate and protect the solar cells, ensuring their efficiency and longevity. The EVA film acts as a barrier against environmental factors such as moisture, dust, and mechanical stress, which can degrade the performance of the solar cells over time. In Monofacial Modules, the transparency and adhesive properties of EVA films are crucial, as they allow maximum light transmission to the solar cells while providing a strong bond that holds the cells in place. The use of EVA films in Monofacial Modules is well-established, and these films continue to play a vital role in maintaining the performance and durability of these solar panels. Bifacial Modules, on the other hand, represent a more advanced technology in the solar industry. These modules have solar cells on both sides, allowing them to capture sunlight from both the front and rear surfaces. This design increases the energy yield of the solar panels, as they can harness reflected and diffused light in addition to direct sunlight. The use of EVA films in Bifacial Modules is critical, as these films must provide protection and encapsulation for both sides of the solar cells. The optical properties of EVA films are particularly important in Bifacial Modules, as they must allow light to pass through to both sides of the cells without significant loss. Additionally, the thermal stability and UV resistance of EVA films are crucial in Bifacial Modules, as these panels are often exposed to more intense sunlight and temperature variations. The development and use of EVA films in Bifacial Modules are driven by the increasing demand for higher efficiency and energy yield in solar panels. As the solar industry continues to innovate and evolve, the role of EVA films in both Monofacial and Bifacial Modules is expected to grow. Manufacturers are focusing on producing EVA films with enhanced optical properties, thermal stability, and UV resistance to meet the specific needs of these advanced solar modules. The ongoing research and development efforts in this field are likely to result in the introduction of new and improved EVA films that can further enhance the performance and efficiency of both Monofacial and Bifacial Modules, contributing to the overall growth of the Global Photovoltaic Packaging EVA Film Market.

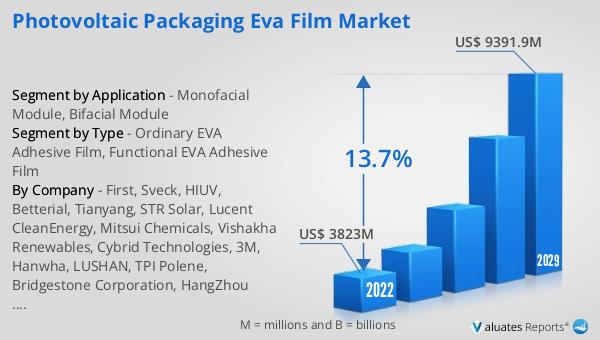

Global Photovoltaic Packaging EVA Film Market Outlook:

The global market for Photovoltaic Packaging EVA Film was valued at approximately $4.883 billion in 2024. This market is anticipated to expand significantly, reaching an estimated size of $11.85 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 13.7% over the forecast period. This impressive growth rate underscores the increasing demand for EVA films in the solar industry, driven by the global shift towards renewable energy sources. As countries worldwide strive to reduce their carbon footprint and transition to cleaner energy solutions, the demand for efficient and reliable solar modules is on the rise. EVA films play a crucial role in this transition by enhancing the performance and lifespan of solar panels. The market is characterized by continuous innovation and technological advancements aimed at improving the efficiency and cost-effectiveness of EVA films. Manufacturers are investing in research and development to produce films with better thermal stability, UV resistance, and optical properties. This market is expected to grow significantly as the global push towards renewable energy intensifies, making EVA films an indispensable component of the solar energy industry. The ongoing research and development efforts in this field are likely to result in the introduction of new and improved EVA films that can further enhance the performance and longevity of solar panels, contributing to the overall growth of the Global Photovoltaic Packaging EVA Film Market.

| Report Metric | Details |

| Report Name | Photovoltaic Packaging EVA Film Market |

| Accounted market size in year | US$ 4883 million |

| Forecasted market size in 2031 | US$ 11850 million |

| CAGR | 13.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | First, Sveck, HIUV, Betterial, Tianyang, STR Solar, Lucent CleanEnergy, Mitsui Chemicals, Vishakha Renewables, Cybrid Technologies, 3M, Hanwha, LUSHAN, TPI Polene, Bridgestone Corporation, HangZhou Solar Composite Energy Science and Technology, Folienwerk Wolfen, Sekisui Chemical, Huichi Industrial Development, SWM, KENGO Industrial |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |