What is Global PGM Recycling and Refining Market?

The Global PGM (Platinum Group Metals) Recycling and Refining Market is a crucial segment within the broader metals industry, focusing on the recovery and purification of precious metals like platinum, palladium, and rhodium. These metals are highly valued for their unique properties, such as resistance to corrosion, high melting points, and excellent catalytic abilities, making them indispensable in various industrial applications. The recycling and refining process involves collecting scrap materials containing PGMs, such as automotive catalytic converters, electronic waste, and industrial catalysts, and then extracting and purifying these metals for reuse. This market is driven by the increasing demand for sustainable and environmentally friendly practices, as recycling PGMs reduces the need for mining, which is often associated with significant environmental impacts. Additionally, the fluctuating prices of these metals on the global market make recycling an economically viable option. The market is characterized by technological advancements in refining processes, which enhance the efficiency and yield of metal recovery. As industries continue to seek sustainable solutions, the Global PGM Recycling and Refining Market is poised to play a pivotal role in meeting the growing demand for these critical metals.

Primary PGM Recycling and Refining, Secondary PGM Recycling and Refining in the Global PGM Recycling and Refining Market:

Primary PGM Recycling and Refining refers to the initial stage of processing where raw materials containing platinum group metals are collected and processed for the first time. This process typically involves the extraction of PGMs from mined ores. The primary recycling process is crucial as it sets the foundation for the quality and purity of the metals that will be used in various applications. The extraction process is complex and requires advanced technology to ensure that the maximum amount of metal is recovered from the ore. This involves crushing the ore, followed by a series of chemical reactions that separate the PGMs from other materials. The refining process then purifies these metals to a high degree, making them suitable for industrial use. Primary recycling is essential for maintaining a steady supply of PGMs, especially given the limited availability of these metals in nature. On the other hand, Secondary PGM Recycling and Refining involves the recovery of PGMs from products that have already been used and discarded. This includes automotive catalytic converters, electronic waste, and industrial catalysts. Secondary recycling is becoming increasingly important as it provides a sustainable way to meet the growing demand for PGMs without the need for additional mining. The process involves collecting and sorting scrap materials, followed by a series of chemical and physical processes to extract and purify the metals. Secondary recycling not only helps in conserving natural resources but also reduces the environmental impact associated with mining and refining. The Global PGM Recycling and Refining Market is witnessing a shift towards secondary recycling due to its environmental benefits and cost-effectiveness. Both primary and secondary recycling processes are integral to the market, ensuring a continuous supply of PGMs for various industries. As technology advances, the efficiency and effectiveness of these processes are expected to improve, further driving the growth of the market. The integration of advanced technologies such as automation and artificial intelligence in the recycling and refining processes is also expected to enhance the overall efficiency and yield of metal recovery. This will not only help in meeting the increasing demand for PGMs but also contribute to the sustainability of the industry. The Global PGM Recycling and Refining Market is thus poised for significant growth, driven by the increasing demand for sustainable and environmentally friendly practices.

New Energy Vehicle, Petrochemical, Medicine, Energy Storage in the Global PGM Recycling and Refining Market:

The Global PGM Recycling and Refining Market plays a significant role in several key industries, including New Energy Vehicles, Petrochemical, Medicine, and Energy Storage. In the New Energy Vehicle sector, PGMs are primarily used in catalytic converters, which help reduce harmful emissions from vehicles. As the demand for cleaner and more efficient vehicles increases, the need for PGMs in this sector is expected to grow. Recycling and refining PGMs ensure a steady supply of these metals, which is crucial for the production of catalytic converters. In the Petrochemical industry, PGMs are used as catalysts in various chemical reactions, including the production of plastics, synthetic rubber, and other chemicals. The recycling and refining of PGMs help maintain a consistent supply of high-quality catalysts, which are essential for the efficient operation of petrochemical processes. In the field of Medicine, PGMs are used in various applications, including medical devices and cancer treatment drugs. The unique properties of these metals make them ideal for use in medical applications, and recycling and refining ensure a reliable supply of high-purity PGMs for the healthcare industry. In Energy Storage, PGMs are used in fuel cells, which are an essential component of clean energy technologies. The recycling and refining of PGMs help support the development and deployment of fuel cell technologies, which are crucial for the transition to a more sustainable energy future. The Global PGM Recycling and Refining Market thus plays a vital role in supporting the growth and development of these key industries by ensuring a steady supply of high-quality PGMs. As the demand for sustainable and environmentally friendly solutions continues to grow, the importance of recycling and refining PGMs is expected to increase, further driving the growth of the market.

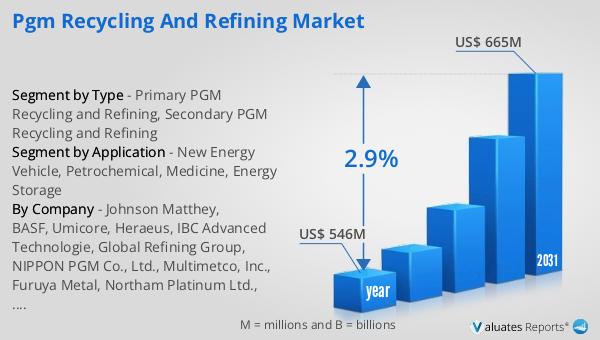

Global PGM Recycling and Refining Market Outlook:

The worldwide market for PGM Recycling and Refining was appraised at $546 million in 2024, with projections indicating it will expand to a revised valuation of $665 million by 2031. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 2.9% throughout the forecast period. This steady growth reflects the increasing demand for sustainable practices and the critical role that PGMs play in various industries. The market's expansion is driven by the need to reduce environmental impact and the economic benefits of recycling these valuable metals. As industries continue to seek ways to minimize their carbon footprint and reduce reliance on mining, the PGM Recycling and Refining Market is poised to become an essential component of the global economy. The projected growth also underscores the importance of technological advancements in refining processes, which enhance the efficiency and yield of metal recovery. As the market continues to evolve, it is expected to play a pivotal role in meeting the growing demand for PGMs, ensuring a sustainable and environmentally friendly supply of these critical metals. The market's outlook is promising, with significant opportunities for growth and development in the coming years.

| Report Metric | Details |

| Report Name | PGM Recycling and Refining Market |

| Accounted market size in year | US$ 546 million |

| Forecasted market size in 2031 | US$ 665 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Johnson Matthey, BASF, Umicore, Heraeus, IBC Advanced Technologie, Global Refining Group, NIPPON PGM Co., Ltd., Multimetco, Inc., Furuya Metal, Northam Platinum Ltd., Metallix Refining Inc., BR Metals Pte Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |