What is Global Anti-Static Coating Market?

The Global Anti-Static Coating Market is a specialized segment within the broader coatings industry, focusing on products designed to reduce or eliminate static electricity. Static electricity can cause significant problems in various industries, leading to equipment malfunctions, dust attraction, and even explosions in extreme cases. Anti-static coatings are applied to surfaces to prevent the buildup of static charges, thereby enhancing safety and performance. These coatings are used in a wide range of applications, from electronics and automotive to aerospace and construction. The market is driven by the increasing demand for electronic devices, the need for safer industrial environments, and the growing awareness of the benefits of anti-static solutions. As industries continue to advance technologically, the demand for anti-static coatings is expected to grow, driven by the need for improved safety and efficiency. The market is characterized by a variety of products, including ready-to-use coatings and concentrates, each offering unique benefits and applications. Companies in this market are continually innovating to develop more effective and environmentally friendly solutions, reflecting the broader trends in the coatings industry towards sustainability and performance enhancement.

Ready-to-Use Anti-Static Coating, Anti-Static Coating Concentrates in the Global Anti-Static Coating Market:

Ready-to-use anti-static coatings and anti-static coating concentrates are two primary product types within the Global Anti-Static Coating Market, each serving distinct needs and applications. Ready-to-use anti-static coatings are pre-formulated solutions that can be directly applied to surfaces without the need for additional mixing or preparation. These coatings are designed for convenience and ease of use, making them ideal for applications where time and efficiency are critical. They are commonly used in environments where quick application and immediate results are necessary, such as in electronic manufacturing facilities or automotive assembly lines. The formulation of ready-to-use coatings typically includes a balanced mix of active ingredients that provide effective static dissipation while ensuring compatibility with a wide range of substrates. On the other hand, anti-static coating concentrates are more versatile products that require dilution or mixing before application. These concentrates offer greater flexibility in terms of formulation, allowing users to adjust the concentration and properties of the coating to suit specific needs. This makes them particularly valuable in industries where custom solutions are required, such as aerospace or specialized electronics manufacturing. By adjusting the concentration, users can tailor the coating's performance characteristics, such as its conductivity, durability, and environmental resistance. This adaptability makes concentrates a popular choice for research and development applications, where precise control over coating properties is essential. Both ready-to-use coatings and concentrates are formulated to provide long-lasting static protection, but they differ in terms of application methods and customization options. Ready-to-use coatings are typically applied using spray, brush, or roller techniques, depending on the surface area and desired finish. They are often chosen for their ease of application and consistent performance across different environments. In contrast, concentrates may require more specialized application equipment and techniques, particularly when used in high-precision industries. Despite these differences, both product types share common goals: to enhance safety, improve product performance, and reduce the risk of static-related issues. The choice between ready-to-use coatings and concentrates often depends on the specific requirements of the application, including factors such as the size of the area to be coated, the desired level of static protection, and the environmental conditions in which the coating will be used. As the Global Anti-Static Coating Market continues to evolve, manufacturers are focusing on developing new formulations that offer improved performance, environmental sustainability, and cost-effectiveness. This includes the use of advanced materials and technologies to enhance the conductivity, durability, and environmental resistance of anti-static coatings. Additionally, there is a growing emphasis on developing coatings that are free from harmful chemicals and comply with stringent environmental regulations. This trend is driven by increasing consumer awareness and regulatory pressures, as well as the desire to reduce the environmental impact of industrial processes. Overall, the Global Anti-Static Coating Market is characterized by a diverse range of products and applications, with ready-to-use coatings and concentrates playing a crucial role in meeting the needs of various industries. As technology continues to advance and industries become more interconnected, the demand for effective and sustainable anti-static solutions is expected to grow, driving innovation and growth in this dynamic market.

Automobile, Electronic Product, Aerospace, Construction, Other in the Global Anti-Static Coating Market:

The Global Anti-Static Coating Market finds extensive usage across various industries, including automobile, electronic products, aerospace, construction, and others, each benefiting from the unique properties of these coatings. In the automobile industry, anti-static coatings are used to enhance the safety and performance of vehicles by preventing static buildup on surfaces such as dashboards, seats, and electronic components. This is particularly important in modern vehicles, which are equipped with a wide range of electronic systems that can be sensitive to static electricity. By reducing static charges, these coatings help prevent malfunctions and improve the overall reliability of automotive electronics. In the electronics industry, anti-static coatings are essential for protecting sensitive components from static discharge, which can cause damage or failure. These coatings are applied to circuit boards, displays, and other electronic parts to ensure their longevity and performance. As the demand for electronic devices continues to grow, the need for effective anti-static solutions becomes increasingly important, driving innovation and development in this sector. The aerospace industry also relies heavily on anti-static coatings to ensure the safety and performance of aircraft. Static electricity can pose significant risks in aerospace applications, where it can interfere with communication systems, navigation equipment, and other critical components. Anti-static coatings are used on both the interior and exterior surfaces of aircraft to prevent static buildup and ensure safe operation. These coatings are designed to withstand the harsh environmental conditions encountered in aerospace applications, including extreme temperatures, humidity, and UV exposure. In the construction industry, anti-static coatings are used to enhance the safety and durability of buildings and infrastructure. These coatings are applied to floors, walls, and other surfaces to prevent static buildup, which can attract dust and dirt, leading to maintenance issues and reduced indoor air quality. By reducing static charges, these coatings help maintain cleaner and safer environments, particularly in facilities such as hospitals, laboratories, and cleanrooms, where hygiene and safety are paramount. Beyond these industries, anti-static coatings are also used in a variety of other applications, including packaging, textiles, and consumer goods. In packaging, these coatings help prevent static buildup on materials such as plastic films and containers, reducing the risk of damage to sensitive products during transportation and storage. In textiles, anti-static coatings are applied to fabrics to improve their comfort and performance, particularly in garments and upholstery. In consumer goods, these coatings are used to enhance the safety and functionality of products such as toys, appliances, and electronics. Overall, the Global Anti-Static Coating Market plays a crucial role in enhancing the safety, performance, and reliability of products across a wide range of industries. As technology continues to advance and industries become more interconnected, the demand for effective and sustainable anti-static solutions is expected to grow, driving innovation and growth in this dynamic market.

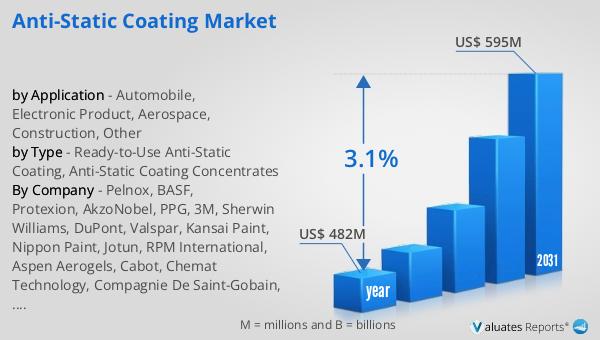

Global Anti-Static Coating Market Outlook:

The worldwide market for anti-static coatings was valued at approximately $482 million in 2024. It is anticipated to expand to a revised size of around $595 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% over the forecast period. This growth trajectory indicates a steady increase in demand for anti-static coatings across various industries. The market's expansion is driven by the rising need for effective static control solutions in sectors such as electronics, automotive, aerospace, and construction. As industries continue to advance technologically, the importance of preventing static-related issues becomes more pronounced, leading to increased adoption of anti-static coatings. The projected growth also reflects the ongoing innovation and development within the market, as manufacturers strive to create more effective and environmentally friendly solutions. This includes the development of new formulations that offer improved performance, durability, and environmental sustainability. Additionally, the market's growth is supported by increasing regulatory pressures and consumer awareness regarding the environmental impact of industrial processes. As a result, companies are focusing on developing coatings that comply with stringent environmental regulations and meet the evolving needs of their customers. Overall, the Global Anti-Static Coating Market is poised for steady growth, driven by the increasing demand for effective and sustainable static control solutions across a wide range of industries.

| Report Metric | Details |

| Report Name | Anti-Static Coating Market |

| Accounted market size in year | US$ 482 million |

| Forecasted market size in 2031 | US$ 595 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Pelnox, BASF, Protexion, AkzoNobel, PPG, 3M, Sherwin Williams, DuPont, Valspar, Kansai Paint, Nippon Paint, Jotun, RPM International, Aspen Aerogels, Cabot, Chemat Technology, Compagnie De Saint-Gobain, NTC Nano Tech Coatings, KANSAI HELIOS Group, Heraeus Holding, Parker Chomerics Division |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |