What is Global Paint Grade Zinc Dust Market?

The Global Paint Grade Zinc Dust Market is a specialized segment within the broader zinc dust industry, focusing specifically on zinc dust used in paint formulations. Zinc dust is a fine powder of zinc metal, and when used in paints, it provides excellent corrosion resistance, making it a critical component in protective coatings. This market is driven by the demand for high-performance coatings that can withstand harsh environmental conditions, such as those found in marine, industrial, and construction settings. The paint grade zinc dust is used primarily in the production of zinc-rich primers, which are applied to steel surfaces to prevent rust and corrosion. These primers are essential in extending the lifespan of metal structures and equipment, reducing maintenance costs, and ensuring safety. The market is influenced by factors such as the growth of the construction and infrastructure sectors, advancements in coating technologies, and increasing awareness about the benefits of zinc-rich coatings. Additionally, environmental regulations promoting the use of eco-friendly and sustainable materials are also contributing to the market's growth. As industries continue to prioritize durability and longevity in their products, the demand for paint grade zinc dust is expected to remain strong.

Ultrafine Zinc Dust, Ordinary Grade in the Global Paint Grade Zinc Dust Market:

Ultrafine Zinc Dust and Ordinary Grade Zinc Dust are two distinct categories within the Global Paint Grade Zinc Dust Market, each serving specific purposes and applications. Ultrafine Zinc Dust is characterized by its extremely small particle size, which enhances its reactivity and surface area. This makes it particularly effective in applications where a high degree of corrosion resistance is required. The ultrafine particles allow for a more uniform distribution within the paint matrix, leading to improved adhesion and protective properties. This type of zinc dust is often used in high-performance coatings that are subjected to severe environmental conditions, such as marine and offshore structures, where the risk of corrosion is significantly higher. The ultrafine nature of the dust also allows for the formulation of thinner coatings without compromising on protection, which can be advantageous in applications where weight and thickness are critical considerations. On the other hand, Ordinary Grade Zinc Dust is typically used in less demanding applications where the environmental conditions are not as harsh. This grade of zinc dust has a larger particle size compared to the ultrafine variant, which can affect the overall performance of the coating. However, it is still highly effective in providing corrosion resistance and is widely used in industrial and construction coatings. Ordinary Grade Zinc Dust is often chosen for its cost-effectiveness, making it a popular choice for projects where budget constraints are a significant factor. Despite its larger particle size, it still offers substantial protection against rust and corrosion, making it suitable for a wide range of applications. The choice between Ultrafine and Ordinary Grade Zinc Dust depends largely on the specific requirements of the application. For instance, in environments where the coating is exposed to saltwater or other corrosive elements, the enhanced properties of Ultrafine Zinc Dust may be necessary to ensure long-term durability. Conversely, in less aggressive environments, Ordinary Grade Zinc Dust may provide sufficient protection at a lower cost. Both grades play a crucial role in the Global Paint Grade Zinc Dust Market, catering to different segments and needs within the industry. The production and supply of these zinc dust grades are influenced by several factors, including the availability of raw materials, technological advancements in production processes, and regulatory standards. Manufacturers are continually seeking ways to improve the quality and performance of zinc dust to meet the evolving demands of the market. This includes developing new formulations that enhance the protective properties of zinc-rich coatings while also addressing environmental concerns. In summary, Ultrafine Zinc Dust and Ordinary Grade Zinc Dust are integral components of the Global Paint Grade Zinc Dust Market, each offering unique benefits and applications. The choice between the two depends on various factors, including environmental conditions, budget constraints, and specific performance requirements. As industries continue to seek durable and cost-effective solutions for corrosion protection, the demand for both ultrafine and ordinary grade zinc dust is expected to remain robust.

Marine Coating, Construction Coating, Petrochemical & Energy Coating, Others in the Global Paint Grade Zinc Dust Market:

The Global Paint Grade Zinc Dust Market finds extensive usage across various sectors, including Marine Coating, Construction Coating, Petrochemical & Energy Coating, and others. In the marine industry, zinc dust is a vital component in coatings used on ships, offshore platforms, and other marine structures. The harsh marine environment, characterized by constant exposure to saltwater and humidity, necessitates the use of high-performance coatings that can prevent corrosion and extend the lifespan of metal surfaces. Zinc-rich primers, formulated with paint grade zinc dust, provide an effective barrier against rust, ensuring the structural integrity and safety of marine vessels and installations. These coatings are essential in reducing maintenance costs and downtime, making them a preferred choice in the marine sector. In the construction industry, paint grade zinc dust is used in coatings applied to steel structures, bridges, and buildings. The primary function of these coatings is to protect the underlying metal from corrosion, which can compromise the structural integrity and safety of construction projects. Zinc-rich coatings are particularly beneficial in environments where steel structures are exposed to moisture, pollutants, and other corrosive elements. By providing a durable and long-lasting protective layer, these coatings help extend the lifespan of construction materials, reduce maintenance requirements, and enhance the overall safety of buildings and infrastructure. The Petrochemical & Energy sector also relies heavily on paint grade zinc dust for protective coatings. In this industry, equipment and structures are often exposed to harsh chemicals, extreme temperatures, and other challenging conditions that can accelerate corrosion. Zinc-rich coatings, formulated with high-quality zinc dust, offer superior protection against these elements, ensuring the longevity and reliability of critical infrastructure. This is particularly important in the petrochemical and energy sectors, where equipment failure can lead to significant financial losses and safety hazards. By using zinc-rich coatings, companies can minimize the risk of corrosion-related issues, improve operational efficiency, and ensure compliance with industry standards and regulations. Beyond these primary sectors, paint grade zinc dust is also used in various other applications, including automotive coatings, industrial machinery, and consumer goods. In the automotive industry, zinc-rich primers are used to protect car bodies and components from rust, enhancing the durability and appearance of vehicles. In industrial settings, zinc dust is used in coatings for machinery and equipment, providing a protective layer that reduces wear and tear and extends the lifespan of assets. Additionally, zinc-rich coatings are used in consumer goods, such as appliances and electronics, to prevent corrosion and improve product longevity. Overall, the Global Paint Grade Zinc Dust Market plays a crucial role in providing effective corrosion protection across a wide range of industries. By offering durable and reliable coatings, zinc dust helps enhance the safety, performance, and longevity of metal structures and equipment, reducing maintenance costs and ensuring compliance with industry standards. As industries continue to prioritize durability and sustainability, the demand for paint grade zinc dust is expected to remain strong, driving innovation and growth in the market.

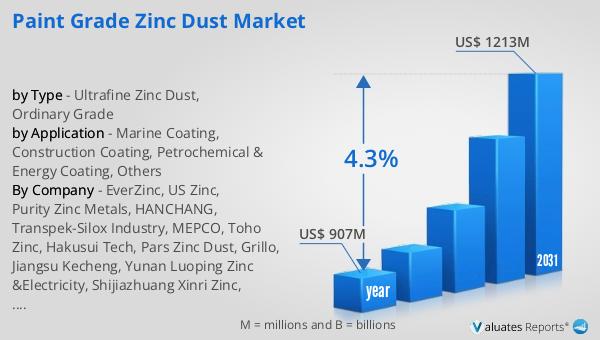

Global Paint Grade Zinc Dust Market Outlook:

In 2024, the global market for Paint Grade Zinc Dust was valued at approximately $907 million. This market is anticipated to grow steadily, reaching an estimated size of $1,213 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. The steady increase in market size reflects the rising demand for high-performance coatings across various industries, including marine, construction, and petrochemical sectors. The growth is driven by the need for durable and reliable protective coatings that can withstand harsh environmental conditions and extend the lifespan of metal structures and equipment. As industries continue to prioritize corrosion protection and sustainability, the demand for paint grade zinc dust is expected to remain robust, supporting the market's expansion. The projected growth also highlights the ongoing advancements in coating technologies and the increasing awareness about the benefits of zinc-rich coatings. As a result, the Global Paint Grade Zinc Dust Market is poised for continued growth, driven by the need for effective corrosion protection solutions across a wide range of applications.

| Report Metric | Details |

| Report Name | Paint Grade Zinc Dust Market |

| Accounted market size in year | US$ 907 million |

| Forecasted market size in 2031 | US$ 1213 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EverZinc, US Zinc, Purity Zinc Metals, HANCHANG, Transpek-Silox Industry, MEPCO, Toho Zinc, Hakusui Tech, Pars Zinc Dust, Grillo, Jiangsu Kecheng, Yunan Luoping Zinc &Electricity, Shijiazhuang Xinri Zinc, Jiangsu Shenlong Zinc, Shandong Xingyuan Zinc, Jiangsu Shuangsheng, Jiangsu Yejian Zinc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |