What is Global PA-MXD6 Market?

The Global PA-MXD6 Market refers to the worldwide industry focused on the production and distribution of polyamide MXD6, a type of nylon known for its excellent barrier properties and mechanical strength. PA-MXD6 is a semi-aromatic polyamide, which means it combines the properties of both aliphatic and aromatic polyamides, resulting in a material that is highly resistant to gas and moisture permeation. This makes it particularly valuable in applications where durability and protection from environmental factors are crucial. The market for PA-MXD6 is driven by its use in various industries, including automotive, packaging, and electronics, where its ability to withstand harsh conditions and maintain structural integrity is highly valued. As industries continue to seek materials that offer both performance and sustainability, PA-MXD6 is increasingly becoming a material of choice due to its recyclability and efficiency in reducing material waste. The global demand for PA-MXD6 is expected to grow as more sectors recognize its benefits, leading to innovations in its applications and production processes. This growth is supported by ongoing research and development efforts aimed at enhancing the properties of PA-MXD6 to meet the evolving needs of different industries.

Injection Molding Grade, Extrusion Grade in the Global PA-MXD6 Market:

In the Global PA-MXD6 Market, two primary grades are commonly used: Injection Molding Grade and Extrusion Grade. Injection Molding Grade PA-MXD6 is specifically formulated for use in injection molding processes, which involve injecting molten material into a mold to create complex shapes and components. This grade is characterized by its high flowability, which allows it to fill intricate molds with precision, making it ideal for producing detailed parts with tight tolerances. The mechanical properties of Injection Molding Grade PA-MXD6, such as its strength and impact resistance, make it suitable for applications in the automotive and electronics industries, where components must withstand mechanical stress and environmental factors. Additionally, its excellent barrier properties make it a preferred choice for packaging applications that require protection against moisture and gases. On the other hand, Extrusion Grade PA-MXD6 is designed for extrusion processes, where the material is forced through a die to create continuous shapes such as films, sheets, or pipes. This grade is optimized for its ability to maintain consistent properties during the extrusion process, ensuring uniformity in the final product. Extrusion Grade PA-MXD6 is valued for its high tensile strength and thermal stability, which are essential for applications in the packaging industry, particularly for food packaging that requires a strong barrier to oxygen and other gases. Its resistance to chemicals and oils also makes it suitable for use in the production of industrial films and coatings. Both Injection Molding Grade and Extrusion Grade PA-MXD6 offer unique advantages that cater to specific manufacturing needs. The choice between these grades depends on the intended application and the specific requirements of the end product. For instance, in the automotive industry, Injection Molding Grade PA-MXD6 might be used for producing under-the-hood components that require precision and durability, while Extrusion Grade PA-MXD6 could be used for manufacturing fuel lines or other continuous components that benefit from its barrier properties. In the packaging sector, the choice of grade would depend on whether the application requires molded containers or extruded films. The versatility of PA-MXD6 in both injection molding and extrusion processes highlights its adaptability to various manufacturing techniques, making it a valuable material in the global market. As industries continue to innovate and develop new applications for PA-MXD6, the demand for both Injection Molding Grade and Extrusion Grade is expected to grow. This growth is further supported by advancements in processing technologies that enhance the performance and efficiency of PA-MXD6, enabling manufacturers to produce high-quality products that meet the stringent demands of modern industries. Overall, the Global PA-MXD6 Market is poised for expansion as it continues to offer solutions that address the challenges of performance, sustainability, and cost-effectiveness in manufacturing.

Automotive, Electrical & Electronics, Mechanical Manufacturing, Other in the Global PA-MXD6 Market:

The Global PA-MXD6 Market finds extensive usage across various industries, including automotive, electrical and electronics, mechanical manufacturing, and others, due to its unique properties. In the automotive sector, PA-MXD6 is highly valued for its strength, durability, and resistance to chemicals and heat. These properties make it an ideal material for manufacturing components such as fuel lines, air intake manifolds, and under-the-hood parts that must withstand harsh operating conditions. The material's excellent barrier properties also contribute to its use in automotive fuel systems, where it helps prevent fuel permeation and enhances the overall efficiency and safety of vehicles. In the electrical and electronics industry, PA-MXD6 is used for producing components that require high dimensional stability and resistance to electrical and thermal stress. Its ability to maintain structural integrity under varying temperatures makes it suitable for connectors, switches, and housings that protect sensitive electronic components. Additionally, PA-MXD6's flame retardant properties are crucial for ensuring safety in electronic devices, making it a preferred choice for manufacturers seeking reliable materials that meet stringent safety standards. Mechanical manufacturing also benefits from the use of PA-MXD6, particularly in applications that demand high mechanical strength and resistance to wear and tear. The material's toughness and ability to withstand mechanical stress make it suitable for gears, bearings, and other components that experience constant motion and friction. Its resistance to oils and chemicals further enhances its suitability for industrial applications, where exposure to harsh substances is common. Beyond these industries, PA-MXD6 is also used in other sectors such as packaging, where its barrier properties are leveraged to protect products from moisture and gas permeation. This is particularly important in food packaging, where maintaining product freshness and extending shelf life are critical. The material's recyclability and environmental benefits also align with the growing demand for sustainable packaging solutions, making it an attractive option for companies looking to reduce their environmental footprint. Overall, the versatility and performance of PA-MXD6 make it a valuable material across multiple industries. Its ability to meet the diverse needs of different applications, from automotive components to electronic devices and packaging solutions, underscores its importance in the global market. As industries continue to evolve and prioritize sustainability and efficiency, the demand for PA-MXD6 is expected to grow, driven by its ability to offer reliable and cost-effective solutions that address the challenges of modern manufacturing.

Global PA-MXD6 Market Outlook:

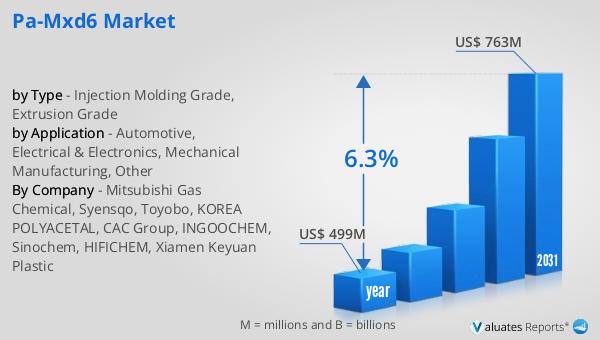

The global market for PA-MXD6 was estimated to be worth approximately $499 million in 2024. Looking ahead, it is anticipated that the market will expand to reach a revised valuation of around $763 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. The increasing demand for PA-MXD6 across various industries, driven by its unique properties and versatility, is a key factor contributing to this market expansion. As industries continue to seek materials that offer both performance and sustainability, PA-MXD6 is increasingly becoming a material of choice due to its recyclability and efficiency in reducing material waste. The global demand for PA-MXD6 is expected to grow as more sectors recognize its benefits, leading to innovations in its applications and production processes. This growth is supported by ongoing research and development efforts aimed at enhancing the properties of PA-MXD6 to meet the evolving needs of different industries. The market's growth is further supported by advancements in processing technologies that enhance the performance and efficiency of PA-MXD6, enabling manufacturers to produce high-quality products that meet the stringent demands of modern industries. Overall, the Global PA-MXD6 Market is poised for expansion as it continues to offer solutions that address the challenges of performance, sustainability, and cost-effectiveness in manufacturing.

| Report Metric | Details |

| Report Name | PA-MXD6 Market |

| Accounted market size in year | US$ 499 million |

| Forecasted market size in 2031 | US$ 763 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsubishi Gas Chemical, Syensqo, Toyobo, KOREA POLYACETAL, CAC Group, INGOOCHEM, Sinochem, HIFICHEM, Xiamen Keyuan Plastic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |