What is Global Non-woven Unidirectional Carbon Fiber Cloth Market?

The Global Non-woven Unidirectional Carbon Fiber Cloth Market is a specialized segment within the broader carbon fiber industry, focusing on materials that are engineered for high-performance applications. Non-woven unidirectional carbon fiber cloth is a type of fabric where carbon fibers are aligned in a single direction, providing exceptional strength and stiffness. This alignment allows for the efficient transfer of loads along the fiber's length, making it ideal for applications requiring high tensile strength and lightweight properties. The non-woven aspect refers to the manufacturing process, where fibers are bonded together without weaving, resulting in a fabric that is both strong and flexible. This market is driven by the increasing demand for lightweight and durable materials in industries such as aerospace, automotive, and wind energy. As these industries continue to seek materials that can enhance performance while reducing weight, the demand for non-woven unidirectional carbon fiber cloth is expected to grow. The market is characterized by technological advancements and innovations aimed at improving the performance characteristics of these materials, making them more accessible and cost-effective for a wider range of applications.

Weft Free Unidirectional Cloth, Sewing Unidirectional Fabric Cloth, Other in the Global Non-woven Unidirectional Carbon Fiber Cloth Market:

Weft Free Unidirectional Cloth, Sewing Unidirectional Fabric Cloth, and other variations within the Global Non-woven Unidirectional Carbon Fiber Cloth Market each serve unique purposes and are tailored to specific applications. Weft Free Unidirectional Cloth is designed to maximize the strength and stiffness of carbon fibers by aligning them in a single direction without any cross-weaving. This type of cloth is particularly beneficial in applications where the primary load is in one direction, such as in the construction of aircraft wings or wind turbine blades. The absence of weft fibers reduces the weight of the fabric and enhances its mechanical properties, making it an ideal choice for high-performance applications where weight savings are critical. On the other hand, Sewing Unidirectional Fabric Cloth incorporates stitching to hold the fibers in place, providing additional stability and ease of handling during the manufacturing process. This type of cloth is often used in applications where complex shapes are required, as the stitching helps maintain the alignment of the fibers during molding and curing. The stitching can also improve the fabric's resistance to delamination, a common issue in composite materials. Other variations in the market include hybrid fabrics that combine carbon fibers with other materials, such as glass or aramid fibers, to achieve specific performance characteristics. These hybrid fabrics can offer a balance of properties, such as improved impact resistance or cost-effectiveness, making them suitable for a broader range of applications. The choice between these different types of unidirectional carbon fiber cloth depends on the specific requirements of the application, including factors such as load direction, environmental conditions, and cost constraints. As the market continues to evolve, manufacturers are investing in research and development to create new fabric configurations that meet the diverse needs of their customers. This includes exploring new bonding techniques, fiber treatments, and fabric architectures that can enhance the performance and versatility of non-woven unidirectional carbon fiber cloth. The ongoing innovation in this field is expected to drive the adoption of these materials across various industries, as they offer a compelling combination of strength, weight savings, and design flexibility.

Wind Energy, Automotive, Other in the Global Non-woven Unidirectional Carbon Fiber Cloth Market:

The Global Non-woven Unidirectional Carbon Fiber Cloth Market finds extensive usage in several key areas, including wind energy, automotive, and other industries. In the wind energy sector, non-woven unidirectional carbon fiber cloth is used in the construction of wind turbine blades. The high strength-to-weight ratio of carbon fiber makes it an ideal material for these applications, as it allows for the production of longer and more efficient blades without significantly increasing their weight. This results in improved energy capture and overall efficiency of wind turbines. Additionally, the durability and resistance to environmental factors such as UV radiation and moisture make carbon fiber cloth a reliable choice for wind energy applications, where components are exposed to harsh conditions over long periods. In the automotive industry, non-woven unidirectional carbon fiber cloth is used to reduce the weight of vehicles while maintaining structural integrity and safety. The lightweight nature of carbon fiber contributes to improved fuel efficiency and reduced emissions, aligning with the industry's goals of sustainability and environmental responsibility. Components such as body panels, chassis, and interior parts can be manufactured using carbon fiber cloth, offering a combination of strength, stiffness, and aesthetic appeal. The use of carbon fiber in automotive applications is particularly prevalent in high-performance and luxury vehicles, where the benefits of weight reduction and enhanced performance are most pronounced. Beyond wind energy and automotive, non-woven unidirectional carbon fiber cloth is also used in other industries such as aerospace, sports equipment, and construction. In aerospace, the material is used in the production of aircraft components, where its lightweight and high-strength properties contribute to fuel efficiency and performance. In sports equipment, carbon fiber cloth is used to manufacture items such as bicycles, tennis rackets, and golf clubs, where the combination of strength and lightness enhances performance and user experience. In construction, carbon fiber cloth is used for structural reinforcement and retrofitting, providing additional strength to buildings and infrastructure without adding significant weight. The versatility and performance characteristics of non-woven unidirectional carbon fiber cloth make it a valuable material across a wide range of applications, driving its demand in the global market.

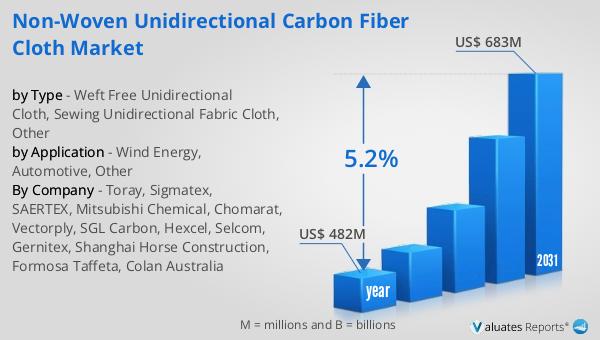

Global Non-woven Unidirectional Carbon Fiber Cloth Market Outlook:

The global market for Non-woven Unidirectional Carbon Fiber Cloth was valued at $482 million in 2024 and is anticipated to grow to a revised size of $683 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% over the forecast period. This growth trajectory underscores the increasing demand for high-performance materials across various industries, driven by the need for lightweight, durable, and efficient solutions. The market's expansion is fueled by advancements in manufacturing technologies and the continuous development of new applications for carbon fiber cloth. As industries such as aerospace, automotive, and wind energy continue to prioritize sustainability and performance, the adoption of non-woven unidirectional carbon fiber cloth is expected to rise. The projected growth also highlights the material's versatility and its ability to meet the evolving needs of different sectors. With ongoing research and development efforts, the market is poised to offer innovative solutions that enhance the performance and efficiency of products across a wide range of applications. The anticipated growth in market size reflects the material's potential to contribute significantly to the advancement of industries seeking to optimize their products and processes.

| Report Metric | Details |

| Report Name | Non-woven Unidirectional Carbon Fiber Cloth Market |

| Accounted market size in year | US$ 482 million |

| Forecasted market size in 2031 | US$ 683 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, Sigmatex, SAERTEX, Mitsubishi Chemical, Chomarat, Vectorply, SGL Carbon, Hexcel, Selcom, Gernitex, Shanghai Horse Construction, Formosa Taffeta, Colan Australia |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |