What is Global Meta-xylenediamine Market?

The global meta-xylenediamine market is a specialized segment within the chemical industry, focusing on the production and distribution of meta-xylenediamine, a chemical compound primarily used as a curing agent and in the production of various polymers. Meta-xylenediamine is a type of diamine, which means it contains two amine groups, and it is derived from xylene, a petrochemical compound. This market is driven by the demand for high-performance materials in industries such as automotive, construction, and electronics, where meta-xylenediamine is used to enhance the properties of epoxy resins and other polymers. The compound's ability to improve the thermal and mechanical properties of materials makes it a valuable component in the manufacturing of durable and heat-resistant products. Additionally, the market is influenced by the growing need for lightweight and fuel-efficient vehicles, which require advanced materials that can withstand high temperatures and mechanical stress. As industries continue to seek innovative solutions to improve product performance and sustainability, the global meta-xylenediamine market is expected to experience steady growth. The market's expansion is also supported by advancements in chemical synthesis and processing technologies, which enable the production of high-purity meta-xylenediamine for various applications.

Purity 99%, Purity 99.5% in the Global Meta-xylenediamine Market:

In the global meta-xylenediamine market, purity levels play a crucial role in determining the quality and performance of the final product. Purity 99% and Purity 99.5% are two common grades of meta-xylenediamine that are widely used in various industrial applications. The purity level of meta-xylenediamine is an indicator of the concentration of the desired compound in the product, with higher purity levels generally associated with better performance and fewer impurities. Purity 99% meta-xylenediamine is often used in applications where a high degree of chemical reactivity and stability is required, such as in the production of epoxy curing agents and high-performance polymers. This grade of meta-xylenediamine is known for its ability to enhance the mechanical and thermal properties of materials, making it a preferred choice for industries that demand robust and durable products. On the other hand, Purity 99.5% meta-xylenediamine is considered a premium grade, offering even higher levels of purity and performance. This grade is typically used in applications where the highest standards of quality and consistency are required, such as in the production of specialty chemicals and advanced materials. The higher purity level ensures that the final product is free from impurities that could affect its performance, making it ideal for use in critical applications where reliability and precision are paramount. The choice between Purity 99% and Purity 99.5% meta-xylenediamine depends on the specific requirements of the application and the desired performance characteristics of the final product. In the global meta-xylenediamine market, manufacturers strive to produce high-purity products to meet the stringent demands of their customers and to maintain a competitive edge in the industry. The production of high-purity meta-xylenediamine involves advanced chemical synthesis and purification processes, which require specialized equipment and expertise. As a result, the market for high-purity meta-xylenediamine is characterized by a limited number of manufacturers who possess the necessary capabilities to produce these high-quality products. The demand for Purity 99% and Purity 99.5% meta-xylenediamine is driven by the growing need for advanced materials in various industries, including automotive, electronics, and construction. These industries require materials that can withstand extreme conditions and provide superior performance, making high-purity meta-xylenediamine an essential component in their production processes. As the global economy continues to evolve and industries seek to improve their products and processes, the demand for high-purity meta-xylenediamine is expected to increase, driving further growth in the market. The ability to produce and supply high-purity meta-xylenediamine is a key factor in the success of manufacturers in this market, as it enables them to meet the diverse needs of their customers and to capitalize on emerging opportunities in the industry.

Epoxy Curing Agent, Nylon MXD6, Resin Raw Materials, Agrochemicals, Others in the Global Meta-xylenediamine Market:

Meta-xylenediamine is a versatile chemical compound with a wide range of applications in various industries. One of its primary uses is as an epoxy curing agent, where it plays a crucial role in the production of epoxy resins. Epoxy resins are widely used in the construction, automotive, and electronics industries due to their excellent adhesive properties, chemical resistance, and mechanical strength. Meta-xylenediamine acts as a hardener in the epoxy curing process, facilitating the cross-linking of polymer chains and resulting in a rigid and durable material. This makes it an essential component in the production of high-performance coatings, adhesives, and composites. In the field of polymer production, meta-xylenediamine is used in the synthesis of Nylon MXD6, a type of nylon known for its exceptional barrier properties and high mechanical strength. Nylon MXD6 is commonly used in the packaging industry for the production of films and containers that require excellent gas barrier properties to preserve the freshness and quality of food products. The use of meta-xylenediamine in the production of Nylon MXD6 enhances the material's performance, making it suitable for demanding applications where durability and resistance to environmental factors are critical. Additionally, meta-xylenediamine serves as a key raw material in the production of various resins, which are used in the manufacturing of coatings, adhesives, and sealants. The compound's ability to improve the thermal and mechanical properties of resins makes it a valuable ingredient in the formulation of high-performance materials that can withstand harsh conditions and provide long-lasting protection. In the agrochemical industry, meta-xylenediamine is used in the synthesis of active ingredients for pesticides and herbicides. Its chemical properties make it an effective building block for the development of compounds that can target specific pests and weeds, providing farmers with efficient solutions for crop protection. The use of meta-xylenediamine in agrochemicals contributes to the development of sustainable agricultural practices by enabling the production of more effective and environmentally friendly products. Beyond these applications, meta-xylenediamine is also used in other industries, such as textiles and pharmaceuticals, where its unique chemical properties are leveraged to enhance product performance and quality. In the textile industry, for example, meta-xylenediamine is used in the production of fibers and fabrics that require high strength and resistance to wear and tear. In the pharmaceutical industry, it serves as an intermediate in the synthesis of active pharmaceutical ingredients, contributing to the development of new and innovative drugs. The diverse applications of meta-xylenediamine in various industries highlight its importance as a versatile and valuable chemical compound. As industries continue to seek advanced materials and solutions to meet the evolving demands of consumers and regulatory requirements, the use of meta-xylenediamine is expected to grow, driving further innovation and development in the market.

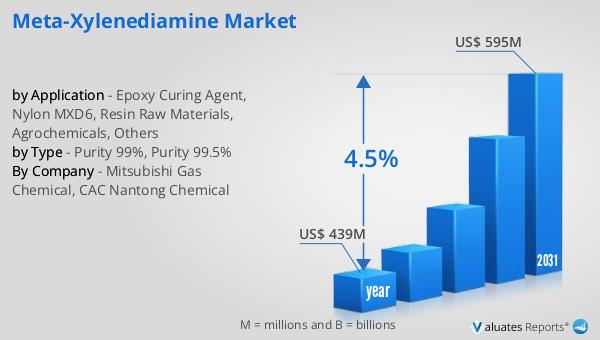

Global Meta-xylenediamine Market Outlook:

The global market for meta-xylenediamine was valued at approximately $439 million in 2024 and is anticipated to expand to a revised size of $595 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth trajectory underscores the increasing demand for meta-xylenediamine across various industries, driven by its essential role in enhancing the performance of materials used in high-demand sectors such as automotive, construction, and electronics. Mitsubishi Gas Chemical stands out as the leading manufacturer in the global meta-xylenediamine market, commanding over 90% of the market share. This dominance is attributed to the company's advanced production capabilities, extensive distribution network, and commitment to quality and innovation. Other notable manufacturers in the market include CAC Nantong Chemical, which also contributes to the supply of meta-xylenediamine, albeit on a smaller scale compared to Mitsubishi Gas Chemical. The market's growth is further supported by technological advancements in chemical synthesis and processing, enabling the production of high-purity meta-xylenediamine that meets the stringent quality standards required by various industries. As the demand for high-performance materials continues to rise, the global meta-xylenediamine market is poised for sustained growth, offering opportunities for manufacturers to expand their product offerings and capture new market segments. The competitive landscape of the market is characterized by a focus on innovation, quality, and customer satisfaction, with leading manufacturers investing in research and development to enhance their product portfolios and maintain their competitive edge. As industries continue to evolve and seek advanced materials to meet the changing needs of consumers and regulatory requirements, the global meta-xylenediamine market is expected to play a pivotal role in driving innovation and development across various sectors.

| Report Metric | Details |

| Report Name | Meta-xylenediamine Market |

| Accounted market size in year | US$ 439 million |

| Forecasted market size in 2031 | US$ 595 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsubishi Gas Chemical, CAC Nantong Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |