What is Global Lump Metal Chrome Market?

The Global Lump Metal Chrome Market is a significant segment within the broader metal industry, focusing on the production and distribution of chrome in its lump form. Chrome, a critical element in various industrial applications, is primarily used for its corrosion resistance and hardness. The market for lump metal chrome is driven by its demand in sectors such as metallurgy, chemical manufacturing, and refractory materials. The extraction and processing of chrome ore into lump form involve mining, beneficiation, and refining processes, which are crucial for ensuring the quality and purity of the final product. The market is influenced by factors such as the availability of raw materials, technological advancements in processing techniques, and the economic conditions of major producing and consuming countries. Additionally, environmental regulations and sustainability practices play a role in shaping the market dynamics, as companies strive to minimize the ecological impact of chrome mining and processing. The global distribution of chrome resources, with significant deposits found in countries like South Africa, Kazakhstan, and India, also affects the market, as geopolitical factors can influence supply chains and pricing. Overall, the Global Lump Metal Chrome Market is a complex and dynamic sector, integral to various industrial processes and applications.

Purity: 98%, Purity: 98.5%, Purity: 99% in the Global Lump Metal Chrome Market:

In the Global Lump Metal Chrome Market, purity levels are a critical factor that determines the quality and applicability of the chrome produced. Purity levels such as 98%, 98.5%, and 99% are indicative of the concentration of chromium in the lump metal, with higher purity levels generally signifying a more refined and valuable product. At a purity level of 98%, the chrome is suitable for a range of industrial applications, including the production of stainless steel and other alloys where corrosion resistance and durability are essential. This level of purity ensures that the chrome can effectively enhance the properties of the metals it is combined with, providing strength and longevity. Moving to a purity level of 98.5%, the chrome becomes even more desirable for specialized applications that require a higher degree of precision and performance. This slight increase in purity can significantly impact the quality of the end product, making it suitable for more demanding industrial processes where even minor impurities could affect the outcome. Finally, at a purity level of 99%, the chrome reaches its highest standard of refinement, making it ideal for the most critical applications where maximum performance and reliability are required. This level of purity is often sought after in high-tech industries and advanced manufacturing processes, where the integrity of the materials used is paramount. The production of high-purity chrome involves advanced refining techniques and stringent quality control measures to ensure that the final product meets the necessary specifications. The demand for different purity levels in the Global Lump Metal Chrome Market is driven by the specific needs of various industries, with higher purity levels generally commanding a premium price due to the increased complexity and cost of production. As industries continue to evolve and demand more sophisticated materials, the importance of purity in the lump metal chrome market is likely to grow, influencing both production practices and market dynamics.

Steelmaking, Casting, Welding Consumables, Others in the Global Lump Metal Chrome Market:

The Global Lump Metal Chrome Market finds extensive usage across several key areas, including steelmaking, casting, welding consumables, and other industrial applications. In steelmaking, chrome is a vital component in the production of stainless steel, where it imparts corrosion resistance, hardness, and a shiny finish. The addition of chrome to steel alloys enhances their durability and performance, making them suitable for a wide range of applications, from construction and automotive manufacturing to household appliances and medical instruments. In casting, chrome is used to improve the wear resistance and strength of cast metal products. The inclusion of chrome in casting alloys helps to produce components that can withstand high temperatures and mechanical stress, making them ideal for use in demanding environments such as aerospace and heavy machinery. Welding consumables, another significant area of application, benefit from the use of chrome to enhance the properties of welding rods and wires. Chrome in welding consumables helps to produce strong, durable welds that are resistant to corrosion and wear, ensuring the longevity and reliability of welded structures. Beyond these primary applications, the Global Lump Metal Chrome Market also serves other industries, including chemical manufacturing and refractory materials. In chemical manufacturing, chrome is used as a catalyst and in the production of various compounds, while in refractory materials, it provides heat resistance and structural integrity to products used in high-temperature environments. The versatility and effectiveness of chrome in these diverse applications underscore its importance in the global market, driving demand and influencing production and distribution strategies. As industries continue to innovate and seek materials that offer superior performance and sustainability, the role of chrome in these applications is likely to expand, further solidifying its position in the market.

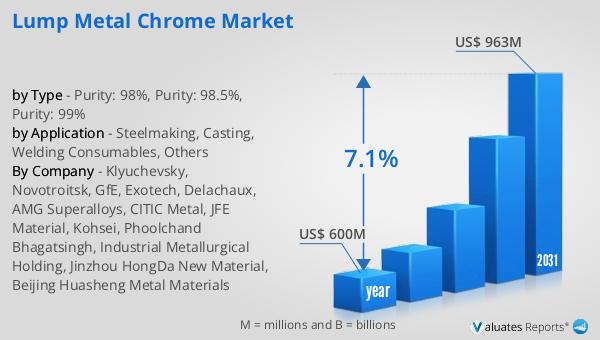

Global Lump Metal Chrome Market Outlook:

The global market for Lump Metal Chrome was valued at approximately 600 million US dollars in 2024. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach a revised size of around 963 million US dollars by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.1% during the forecast period. The increasing demand for chrome in various industrial applications, such as steelmaking, casting, and welding consumables, is a key driver of this growth. As industries continue to evolve and seek materials that offer enhanced performance and sustainability, the demand for high-quality chrome is expected to rise. Additionally, advancements in mining and refining technologies are likely to improve the efficiency and cost-effectiveness of chrome production, further supporting market expansion. The global distribution of chrome resources, along with geopolitical factors, will also play a role in shaping the market dynamics, influencing supply chains and pricing. As the market continues to grow, companies operating in the Lump Metal Chrome sector will need to adapt to changing conditions and capitalize on emerging opportunities to maintain their competitive edge.

| Report Metric | Details |

| Report Name | Lump Metal Chrome Market |

| Accounted market size in year | US$ 600 million |

| Forecasted market size in 2031 | US$ 963 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Klyuchevsky, Novotroitsk, GfE, Exotech, Delachaux, AMG Superalloys, CITIC Metal, JFE Material, Kohsei, Phoolchand Bhagatsingh, Industrial Metallurgical Holding, Jinzhou HongDa New Material, Beijing Huasheng Metal Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |