What is Global Low Melt Polyester Fiber Market?

The Global Low Melt Polyester Fiber Market is a specialized segment within the broader polyester fiber industry, focusing on fibers that have a lower melting point compared to standard polyester fibers. These fibers are engineered to melt at lower temperatures, making them ideal for applications that require bonding or fusing without the need for high heat. This unique property allows them to be used in a variety of industries, including textiles, automotive, and furniture, where they serve as a bonding agent or adhesive. The market for low melt polyester fibers is driven by their versatility and the growing demand for more efficient and environmentally friendly manufacturing processes. As industries seek to reduce energy consumption and improve product performance, low melt polyester fibers offer a compelling solution. They are particularly valued for their ability to enhance the durability and quality of end products while also contributing to cost savings in production. The market is characterized by a diverse range of products, each tailored to meet specific industry needs, and is supported by ongoing research and development efforts aimed at expanding their applications and improving their performance.

Melting Point Below 130℃, Melting Point Above 130℃ in the Global Low Melt Polyester Fiber Market:

In the Global Low Melt Polyester Fiber Market, the melting point of the fibers is a critical factor that determines their suitability for various applications. Fibers with a melting point below 130℃ are particularly advantageous in applications where low-temperature bonding is required. These fibers can be used in processes that involve delicate materials or where energy efficiency is a priority. For instance, in the textile industry, low melt fibers with a melting point below 130℃ can be used to create nonwoven fabrics that require minimal heat for bonding, thus preserving the integrity of other materials involved. This characteristic is also beneficial in the automotive industry, where components may need to be bonded without exposing them to high temperatures that could cause damage or deformation. On the other hand, fibers with a melting point above 130℃ are used in applications that require more robust bonding or where higher temperatures are not a concern. These fibers are often employed in the production of durable goods that need to withstand higher levels of stress or wear. In the furniture industry, for example, fibers with a higher melting point can be used to create strong, resilient upholstery that maintains its shape and appearance over time. The choice between low and high melting point fibers depends largely on the specific requirements of the application, including the materials involved, the desired properties of the final product, and the manufacturing processes used. As the market for low melt polyester fibers continues to grow, manufacturers are increasingly focusing on developing products that offer a balance between performance and cost-effectiveness, catering to the diverse needs of industries around the world. The ongoing advancements in fiber technology are expected to further expand the range of applications for both low and high melting point fibers, driving innovation and growth in the market.

Textile, Automobile, Furniture, Others in the Global Low Melt Polyester Fiber Market:

The Global Low Melt Polyester Fiber Market finds extensive usage across various industries, each leveraging the unique properties of these fibers to enhance product quality and manufacturing efficiency. In the textile industry, low melt polyester fibers are used to produce nonwoven fabrics, which are essential for creating a wide range of products, from clothing to industrial textiles. These fibers provide excellent bonding capabilities, allowing manufacturers to produce fabrics that are both durable and lightweight. The ability to bond at lower temperatures also helps in preserving the quality of other materials used in textile production, making them an ideal choice for high-performance fabrics. In the automotive industry, low melt polyester fibers are used in the production of interior components such as seat covers, headliners, and door panels. Their ability to bond materials without the need for high heat makes them suitable for use with delicate components that could be damaged by excessive temperatures. This not only improves the durability and appearance of automotive interiors but also contributes to energy savings during the manufacturing process. In the furniture industry, these fibers are used to create upholstery and padding materials that offer superior comfort and resilience. The low melting point allows for efficient bonding of layers, resulting in furniture that maintains its shape and comfort over time. Additionally, the use of low melt polyester fibers in furniture production can lead to cost savings by reducing the need for additional adhesives or bonding agents. Beyond these industries, low melt polyester fibers are also used in various other applications, including filtration, construction, and packaging. Their versatility and performance make them a valuable material for any industry looking to improve product quality and manufacturing efficiency. As the demand for sustainable and efficient manufacturing processes continues to grow, the Global Low Melt Polyester Fiber Market is poised to play a crucial role in meeting these needs.

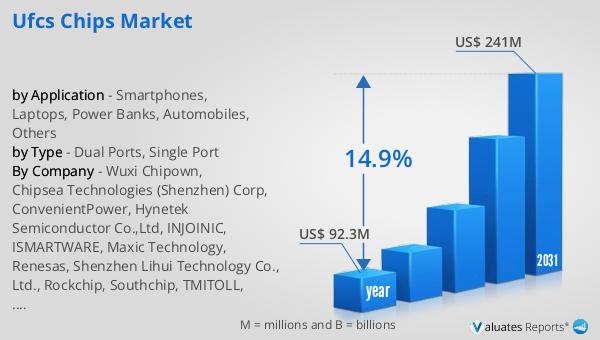

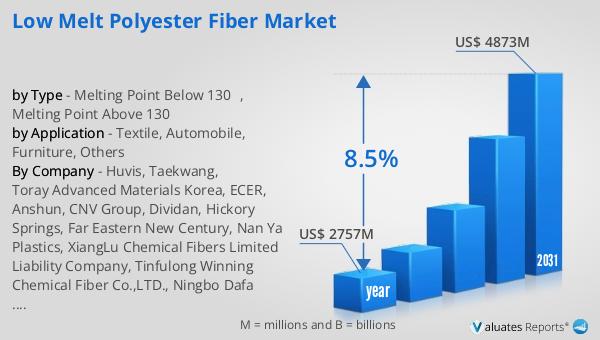

Global Low Melt Polyester Fiber Market Outlook:

The global market for Low Melt Polyester Fiber was valued at approximately $2,757 million in 2024, with projections indicating a significant growth trajectory. By 2031, the market is expected to reach a revised size of around $4,873 million, reflecting a compound annual growth rate (CAGR) of 8.5% over the forecast period. This robust growth is indicative of the increasing demand for low melt polyester fibers across various industries, driven by their unique properties and the advantages they offer in manufacturing processes. The market is dominated by the top three companies, which collectively hold a market share exceeding 40%. This concentration of market power highlights the competitive landscape and the importance of innovation and product development in maintaining a leading position. As industries continue to seek materials that offer both performance and sustainability, low melt polyester fibers are well-positioned to meet these demands. The ongoing advancements in fiber technology and the expanding range of applications are expected to further drive market growth, offering opportunities for both established players and new entrants. The market outlook suggests a promising future for low melt polyester fibers, with their role in enhancing product quality and manufacturing efficiency becoming increasingly recognized across the globe.

| Report Metric | Details |

| Report Name | Low Melt Polyester Fiber Market |

| Accounted market size in year | US$ 2757 million |

| Forecasted market size in 2031 | US$ 4873 million |

| CAGR | 8.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Huvis, Taekwang, Toray Advanced Materials Korea, ECER, Anshun, CNV Group, Dividan, Hickory Springs, Far Eastern New Century, Nan Ya Plastics, XiangLu Chemical Fibers Limited Liability Company, Tinfulong Winning Chemical Fiber Co.,LTD., Ningbo Dafa Chemical Fiber Co., Ltd, Shyam Fibers, Sinopec Yizheng Chemical Fiber Co.,LTD |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |