What is Global Hydrophobic Coating for Medical Devices Market?

The Global Hydrophobic Coating for Medical Devices Market is a specialized segment within the broader medical device industry, focusing on the application of hydrophobic coatings to various medical devices. These coatings are designed to repel water, thereby reducing friction and enhancing the performance and longevity of medical devices. Hydrophobic coatings are particularly valuable in medical applications where moisture control is critical, such as in surgical instruments, diagnostic equipment, and implantable devices. By minimizing the interaction with bodily fluids, these coatings help in maintaining the sterility and functionality of medical devices. The market for hydrophobic coatings is driven by the increasing demand for minimally invasive surgical procedures, which require highly reliable and efficient medical devices. Additionally, advancements in coating technologies have led to the development of more durable and effective hydrophobic coatings, further propelling market growth. The global market is characterized by a diverse range of products and applications, catering to various medical needs and requirements. As healthcare systems worldwide continue to evolve, the demand for advanced medical devices with enhanced performance characteristics is expected to rise, thereby boosting the market for hydrophobic coatings.

Polymers Substrate, Glass/Ceramics Substrate, Nanoparticles Substrate, Other in the Global Hydrophobic Coating for Medical Devices Market:

In the Global Hydrophobic Coating for Medical Devices Market, substrates play a crucial role in determining the effectiveness and application of the coatings. Polymers, glass/ceramics, nanoparticles, and other substrates each offer unique properties that make them suitable for specific medical applications. Polymers are widely used as substrates due to their versatility, lightweight nature, and cost-effectiveness. They are commonly found in disposable medical devices and equipment, where hydrophobic coatings can enhance their performance by reducing friction and preventing moisture accumulation. The flexibility of polymers allows for easy integration with various coating technologies, making them a popular choice in the medical industry. Glass and ceramics substrates, on the other hand, are known for their durability and resistance to high temperatures and chemical reactions. These properties make them ideal for use in medical devices that require sterilization and long-term use, such as surgical instruments and diagnostic equipment. Hydrophobic coatings on glass and ceramics help maintain clarity and prevent fogging, ensuring optimal performance during medical procedures. Nanoparticles substrates represent a more advanced and innovative approach in the hydrophobic coating market. By incorporating nanoparticles into the coating process, manufacturers can achieve superior water-repellent properties and enhanced durability. This technology is particularly beneficial for implantable devices, where long-term performance and biocompatibility are critical. The use of nanoparticles also opens up possibilities for multifunctional coatings that can provide additional benefits, such as antimicrobial properties. Other substrates, including metals and composites, also play a role in the hydrophobic coating market. Metals are often used in surgical tools and implants, where coatings can reduce friction and improve wear resistance. Composites, which combine different materials to achieve specific properties, offer a customizable solution for medical devices with unique requirements. The choice of substrate depends on the intended application and desired performance characteristics of the medical device. Each substrate type presents its own set of challenges and opportunities, influencing the development and adoption of hydrophobic coatings in the medical field. As technology continues to advance, the exploration of new substrates and coating techniques is expected to drive innovation and growth in the Global Hydrophobic Coating for Medical Devices Market.

Guide Wire, Catheter, Other in the Global Hydrophobic Coating for Medical Devices Market:

The usage of Global Hydrophobic Coating for Medical Devices Market is particularly prominent in areas such as guide wires, catheters, and other medical devices. Guide wires, which are essential tools in minimally invasive procedures, benefit significantly from hydrophobic coatings. These coatings reduce friction between the guide wire and the surrounding tissues, allowing for smoother navigation through the body's intricate pathways. This not only enhances the precision and efficiency of the procedure but also minimizes the risk of tissue damage and patient discomfort. In addition, hydrophobic coatings help maintain the sterility of guide wires by preventing the accumulation of bodily fluids and contaminants. Catheters, another critical component in various medical procedures, also gain from the application of hydrophobic coatings. These coatings improve the catheter's performance by reducing friction and preventing the adhesion of proteins and other substances. This is particularly important in urinary and cardiovascular catheters, where smooth and efficient operation is crucial for patient safety and comfort. Hydrophobic coatings also contribute to the longevity of catheters by protecting them from wear and tear, thereby reducing the need for frequent replacements. Beyond guide wires and catheters, hydrophobic coatings find applications in a wide range of other medical devices. Surgical instruments, for instance, benefit from these coatings by maintaining their sharpness and preventing corrosion. Diagnostic equipment, such as endoscopes and imaging devices, also utilize hydrophobic coatings to ensure clear and accurate results by preventing fogging and moisture interference. Implantable devices, including stents and pacemakers, rely on hydrophobic coatings to enhance their biocompatibility and reduce the risk of infection. The versatility and effectiveness of hydrophobic coatings make them an invaluable asset in the medical field, contributing to improved patient outcomes and the overall efficiency of healthcare systems. As the demand for advanced medical devices continues to grow, the role of hydrophobic coatings in enhancing their performance and reliability is expected to become increasingly significant.

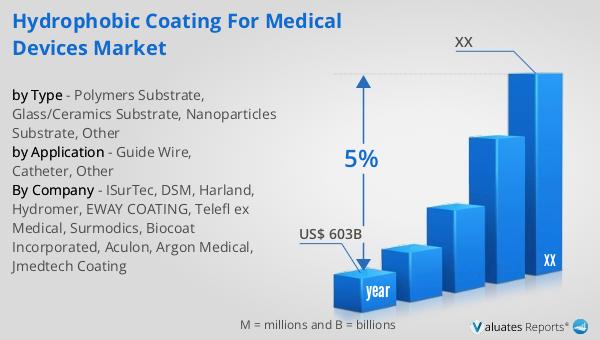

Global Hydrophobic Coating for Medical Devices Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately USD 603 billion in 2023, with an anticipated growth rate of 5% CAGR over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the rising demand for minimally invasive procedures. The medical device industry is a dynamic and rapidly evolving sector, characterized by continuous innovation and the development of new products and technologies. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the demand for efficient and reliable medical devices is expected to rise. The market for hydrophobic coatings, in particular, is poised for growth as these coatings enhance the performance and longevity of medical devices. By reducing friction, preventing moisture accumulation, and improving biocompatibility, hydrophobic coatings contribute to the overall effectiveness and safety of medical devices. As a result, manufacturers are increasingly investing in research and development to create more advanced and durable coatings that meet the evolving needs of the healthcare industry. The global market outlook for medical devices, including hydrophobic coatings, remains positive, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Hydrophobic Coating for Medical Devices Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ISurTec, DSM, Harland, Hydromer, EWAY COATING, Telefl ex Medical, Surmodics, Biocoat Incorporated, Aculon, Argon Medical, Jmedtech Coating |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |