What is Global HJT Low Temperature Silver Paste Market?

The Global HJT Low Temperature Silver Paste Market is a specialized segment within the broader silver paste industry, focusing on the production and application of silver pastes that operate efficiently at low temperatures. These pastes are crucial in the manufacturing of heterojunction technology (HJT) solar cells, which are known for their high efficiency and performance. The low-temperature aspect is significant because it allows for the use of less energy during the manufacturing process, reducing costs and environmental impact. This market is driven by the increasing demand for renewable energy sources and the need for more efficient solar technologies. As countries worldwide strive to meet their renewable energy targets, the demand for HJT solar cells, and consequently low-temperature silver pastes, is expected to grow. The market is characterized by continuous innovation and development, with companies investing in research to improve the performance and cost-effectiveness of their products. The global reach of this market is evident as it caters to solar panel manufacturers across various regions, each with its unique energy needs and regulatory environments. The growth of this market is a testament to the ongoing shift towards sustainable energy solutions.

Front Side Silver Paste, Back Side Silver Paste in the Global HJT Low Temperature Silver Paste Market:

Front Side Silver Paste and Back Side Silver Paste are integral components of the Global HJT Low Temperature Silver Paste Market, each serving distinct roles in the production of HJT solar cells. Front Side Silver Paste is primarily used on the front side of solar cells, where it plays a critical role in forming the electrical contacts that collect and transport the generated electricity. This paste must possess excellent conductivity and adhesion properties to ensure efficient energy transfer and long-term durability. It is formulated to withstand the environmental conditions that solar panels are exposed to, such as UV radiation and temperature fluctuations. The paste's low-temperature curing capability is particularly important as it minimizes thermal stress on the solar cells, preserving their efficiency and lifespan. On the other hand, Back Side Silver Paste is applied to the rear side of the solar cells. Its primary function is to form a conductive layer that facilitates the flow of electricity from the cell to the external circuit. This paste also needs to exhibit high conductivity and strong adhesion to the cell's surface. Additionally, it must be compatible with the cell's materials to prevent any adverse chemical reactions that could degrade performance. The development of both Front Side and Back Side Silver Pastes involves a delicate balance of chemistry and engineering. Manufacturers must consider factors such as particle size, binder composition, and solvent systems to optimize the paste's performance. Innovations in these areas can lead to significant improvements in the efficiency and cost-effectiveness of HJT solar cells. As the demand for renewable energy continues to rise, the importance of high-quality silver pastes in solar cell manufacturing cannot be overstated. Companies in this market are constantly exploring new formulations and production techniques to meet the evolving needs of the solar industry. The competition in this market is fierce, with players striving to offer products that deliver superior performance at competitive prices. This drive for innovation is not only beneficial for the companies involved but also for the broader goal of advancing solar technology and increasing the adoption of clean energy solutions worldwide.

Photovoltaic(PV), Building Integrated Photovoltaic(BIPV) in the Global HJT Low Temperature Silver Paste Market:

The usage of Global HJT Low Temperature Silver Paste Market in the areas of Photovoltaic (PV) and Building Integrated Photovoltaic (BIPV) is pivotal in advancing solar energy technologies. In the realm of Photovoltaic (PV) applications, HJT low-temperature silver paste is essential for the production of high-efficiency solar cells. These cells are at the heart of solar panels, converting sunlight into electricity. The low-temperature curing capability of the silver paste is crucial in this context, as it allows for the production of solar cells with minimal thermal stress, thereby enhancing their efficiency and longevity. The paste's excellent conductivity ensures that the electricity generated by the solar cells is efficiently collected and transported, maximizing the overall energy output of the solar panels. This is particularly important in large-scale solar farms, where even small improvements in efficiency can lead to significant increases in energy production. In Building Integrated Photovoltaic (BIPV) applications, the role of HJT low-temperature silver paste is equally significant. BIPV involves the integration of solar cells into building materials, such as windows, facades, and roofs, allowing buildings to generate their own electricity. The use of low-temperature silver paste in BIPV applications is advantageous because it enables the production of solar cells that can be seamlessly integrated into various building materials without compromising their structural integrity. This is achieved through the paste's ability to cure at low temperatures, which reduces the risk of damaging sensitive building materials during the manufacturing process. Moreover, the high conductivity of the silver paste ensures that the electricity generated by the integrated solar cells is efficiently harnessed, contributing to the building's overall energy efficiency. The adoption of BIPV is growing as more architects and builders recognize the benefits of integrating renewable energy sources into building designs. The use of HJT low-temperature silver paste in both PV and BIPV applications underscores its importance in the transition towards sustainable energy solutions. As the demand for clean energy continues to rise, the development and application of advanced materials like low-temperature silver paste will play a crucial role in meeting global energy needs. The ongoing research and innovation in this field are expected to lead to further improvements in the performance and cost-effectiveness of solar technologies, driving their adoption across various sectors.

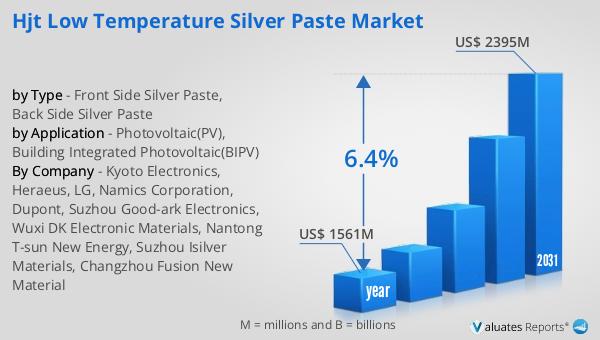

Global HJT Low Temperature Silver Paste Market Outlook:

The global market for HJT Low Temperature Silver Paste is on a growth trajectory, with its value estimated at US$ 1561 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of US$ 2395 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 6.4% over the forecast period. This upward trend reflects the increasing demand for efficient and cost-effective solar technologies, driven by the global push towards renewable energy sources. The market's expansion is supported by advancements in HJT solar cell technology, which require high-performance silver pastes to achieve optimal efficiency. The low-temperature curing capability of these pastes is a key factor in their growing popularity, as it reduces energy consumption during the manufacturing process and enhances the durability of the solar cells. The market's growth is also fueled by the rising adoption of solar energy in various regions, as countries strive to meet their renewable energy targets and reduce their carbon footprint. As the market continues to evolve, companies are investing in research and development to improve the performance and cost-effectiveness of their silver paste products. This focus on innovation is expected to drive further growth in the market, as manufacturers seek to meet the increasing demand for high-quality solar technologies. The global HJT Low Temperature Silver Paste Market is poised for significant expansion, reflecting the broader trend towards sustainable energy solutions and the ongoing efforts to combat climate change.

| Report Metric | Details |

| Report Name | HJT Low Temperature Silver Paste Market |

| Accounted market size in year | US$ 1561 million |

| Forecasted market size in 2031 | US$ 2395 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kyoto Electronics, Heraeus, LG, Namics Corporation, Dupont, Suzhou Good-ark Electronics, Wuxi DK Electronic Materials, Nantong T-sun New Energy, Suzhou Isilver Materials, Changzhou Fusion New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |