What is Global High-purity Isotopic Copper Powder Market?

The Global High-purity Isotopic Copper Powder Market is a specialized segment within the broader copper powder industry, focusing on the production and distribution of copper powders with exceptionally high isotopic purity. These powders are characterized by their precise isotopic composition, which is achieved through advanced separation and purification techniques. High-purity isotopic copper powders are essential in various high-tech applications due to their unique properties, such as enhanced electrical conductivity and thermal stability. These properties make them highly sought after in industries like electronics, where they are used in the manufacturing of semiconductors and other electronic components. Additionally, their purity levels make them suitable for use in scientific research and specialized chemical processes. The market for these powders is driven by the increasing demand for advanced materials in technology-driven sectors, as well as the ongoing advancements in isotopic separation technologies that make the production of such high-purity materials feasible and cost-effective. As industries continue to innovate and require materials with specific isotopic compositions, the demand for high-purity isotopic copper powders is expected to grow, making this market a critical component of the materials science landscape.

6N, 7N, Others in the Global High-purity Isotopic Copper Powder Market:

In the Global High-purity Isotopic Copper Powder Market, the terms 6N, 7N, and others refer to the purity levels of the copper powders, with each designation indicating the number of nines in the purity percentage. For instance, 6N copper powder has a purity of 99.9999%, while 7N copper powder boasts an even higher purity of 99.99999%. These purity levels are crucial for applications that require minimal impurities to ensure optimal performance. The production of 6N and 7N copper powders involves sophisticated purification processes, often utilizing advanced techniques such as zone refining and chemical vapor deposition. These methods help in achieving the desired isotopic composition and purity by removing trace elements and contaminants. The choice between 6N, 7N, and other purity levels depends on the specific requirements of the application. For example, in the electronics industry, where even the slightest impurity can affect the performance of semiconductors, 7N copper powder might be preferred. On the other hand, 6N copper powder could be sufficient for applications where the tolerance for impurities is slightly higher. The demand for these high-purity copper powders is influenced by the rapid advancements in technology and the increasing complexity of electronic devices, which necessitate materials with superior purity and performance characteristics. Furthermore, the production of these powders is not only about achieving high purity but also about maintaining consistency in isotopic composition, which is critical for applications in scientific research and specialized industrial processes. The market for 6N, 7N, and other high-purity isotopic copper powders is thus driven by the need for precision and reliability in high-tech applications, as well as the ongoing innovations in purification technologies that enable the production of such advanced materials. As industries continue to push the boundaries of technology, the demand for high-purity isotopic copper powders is expected to rise, making them an integral part of the materials science and technology landscape.

Electronics, Chemical Industry, Others in the Global High-purity Isotopic Copper Powder Market:

The usage of Global High-purity Isotopic Copper Powder Market spans several key areas, including electronics, the chemical industry, and other specialized sectors. In the electronics industry, high-purity isotopic copper powders are indispensable due to their superior electrical conductivity and thermal properties. They are used in the production of semiconductors, printed circuit boards, and other electronic components where precision and performance are paramount. The high purity levels of these powders ensure minimal electrical resistance and optimal thermal management, which are critical for the efficient functioning of electronic devices. As electronic devices become more compact and complex, the demand for materials that can meet these stringent requirements continues to grow. In the chemical industry, high-purity isotopic copper powders are used as catalysts in various chemical reactions. Their unique isotopic composition and high surface area make them effective in facilitating reactions that require precise control over reaction conditions and outcomes. These powders are also used in the production of specialty chemicals and materials, where their purity and isotopic composition can significantly influence the properties of the final product. Beyond electronics and chemicals, high-purity isotopic copper powders find applications in other areas such as scientific research and advanced manufacturing. In research settings, they are used in experiments that require materials with specific isotopic compositions to study fundamental processes and develop new technologies. In advanced manufacturing, these powders are used in additive manufacturing and other cutting-edge techniques that require materials with exceptional purity and performance characteristics. The versatility and unique properties of high-purity isotopic copper powders make them a valuable resource across various industries, driving innovation and enabling the development of new technologies and products. As the demand for high-performance materials continues to rise, the role of high-purity isotopic copper powders in these key areas is expected to expand, further solidifying their importance in the global market.

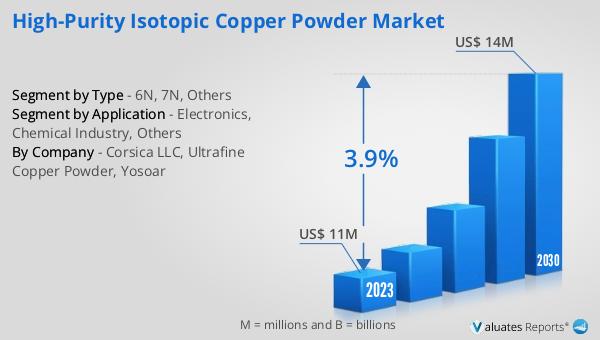

Global High-purity Isotopic Copper Powder Market Outlook:

The global market for High-purity Isotopic Copper Powder was valued at US$ 11.7 million in 2024 and is projected to reach a revised size of US$ 15.2 million by 2031, growing at a compound annual growth rate (CAGR) of 3.9% during the forecast period. This growth trajectory highlights the increasing demand for high-purity isotopic copper powders across various industries. The market's expansion is driven by the rising need for advanced materials in technology-driven sectors, where the unique properties of these powders are essential for achieving optimal performance. The electronics industry, in particular, is a significant contributor to this growth, as the demand for high-performance electronic components continues to rise. Additionally, advancements in isotopic separation technologies have made the production of high-purity isotopic copper powders more feasible and cost-effective, further fueling market growth. As industries continue to innovate and require materials with specific isotopic compositions, the demand for high-purity isotopic copper powders is expected to grow, making this market a critical component of the materials science landscape. The projected growth of the market underscores the importance of these powders in enabling technological advancements and meeting the evolving needs of various industries.

| Report Metric | Details |

| Report Name | High-purity Isotopic Copper Powder Market |

| Accounted market size in year | US$ 11.7 million |

| Forecasted market size in 2031 | US$ 15.2 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Corsica LLC, Ultrafine Copper Powder, Yosoar |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |