What is Global Heat Preservation Concrete Pipe Market?

The Global Heat Preservation Concrete Pipe Market is a specialized segment within the construction and infrastructure industry that focuses on the development and distribution of concrete pipes designed to maintain temperature consistency. These pipes are essential in various applications where temperature control is crucial, such as in heating systems, industrial processes, and municipal infrastructure. The primary function of these pipes is to minimize heat loss, thereby improving energy efficiency and reducing operational costs. This market has gained significant attention due to the increasing demand for energy-efficient solutions and the growing emphasis on sustainable construction practices. The pipes are typically made from high-quality concrete materials that are enhanced with insulating properties, ensuring durability and effective heat preservation. As urbanization and industrialization continue to rise globally, the need for efficient heat preservation solutions is expected to grow, driving the demand for these specialized concrete pipes. The market is characterized by a diverse range of products tailored to meet specific requirements, including variations in size, insulation thickness, and installation methods. Overall, the Global Heat Preservation Concrete Pipe Market plays a crucial role in supporting sustainable development and energy conservation efforts worldwide.

Direct Burial Heat Preservation Pipe, Overhead Heat Preservation Pipe in the Global Heat Preservation Concrete Pipe Market:

Direct Burial Heat Preservation Pipes and Overhead Heat Preservation Pipes are two primary types of products within the Global Heat Preservation Concrete Pipe Market, each serving distinct purposes and applications. Direct Burial Heat Preservation Pipes are designed to be installed underground, providing a robust solution for maintaining temperature consistency in buried systems. These pipes are particularly useful in applications where space constraints or aesthetic considerations necessitate underground installation. They are constructed with layers of insulation materials that protect against heat loss, ensuring that the temperature of the fluid or gas being transported remains stable. This type of pipe is commonly used in district heating systems, where hot water or steam is distributed from a central location to residential or commercial buildings. The underground installation helps in minimizing heat loss to the surrounding environment, thereby enhancing energy efficiency and reducing operational costs. Additionally, the use of concrete as a primary material provides these pipes with excellent durability and resistance to external pressures, making them suitable for long-term use in various environmental conditions. On the other hand, Overhead Heat Preservation Pipes are installed above ground and are often used in situations where underground installation is not feasible or practical. These pipes are typically used in industrial settings, where they transport heated fluids or gases across large facilities. The overhead installation allows for easy access and maintenance, which is crucial in industrial environments where regular inspections and repairs may be necessary. Like their underground counterparts, Overhead Heat Preservation Pipes are designed with insulating materials that prevent heat loss, ensuring that the transported medium maintains its desired temperature. This is particularly important in industrial processes where temperature control is critical to maintaining product quality and process efficiency. The use of concrete in these pipes provides additional benefits, such as resistance to corrosion and mechanical damage, which are common challenges in industrial settings. Moreover, the overhead installation can help in optimizing space utilization within industrial facilities, as it allows for the transportation of fluids or gases without interfering with ground-level operations. Both Direct Burial and Overhead Heat Preservation Pipes are integral components of the Global Heat Preservation Concrete Pipe Market, catering to different needs and applications. The choice between these two types of pipes depends on various factors, including the specific requirements of the project, environmental conditions, and budget constraints. For instance, projects that require minimal visual impact or have limited space for above-ground installations may opt for Direct Burial Pipes. In contrast, industrial facilities that prioritize ease of access and maintenance may prefer Overhead Pipes. Regardless of the type, both categories of heat preservation pipes contribute significantly to energy conservation efforts by minimizing heat loss and improving the overall efficiency of heating systems. As the demand for sustainable and energy-efficient solutions continues to grow, the market for these specialized concrete pipes is expected to expand, offering a wide range of options to meet the diverse needs of different industries and applications.

Municipal Engineering, Industrial, Agricultural Irrigation System in the Global Heat Preservation Concrete Pipe Market:

The Global Heat Preservation Concrete Pipe Market finds extensive usage across various sectors, including municipal engineering, industrial applications, and agricultural irrigation systems, each benefiting from the unique properties of these specialized pipes. In municipal engineering, heat preservation concrete pipes are crucial for the efficient distribution of heating and cooling systems within urban areas. These pipes are often used in district heating networks, where they transport hot water or steam from a central plant to residential and commercial buildings. The ability of these pipes to minimize heat loss ensures that the energy generated at the central plant is effectively utilized, reducing the overall energy consumption and operational costs for municipalities. Additionally, the durability and longevity of concrete pipes make them a cost-effective solution for municipal infrastructure projects, as they require less frequent maintenance and replacement compared to other materials. In industrial applications, heat preservation concrete pipes play a vital role in maintaining temperature consistency in various processes. Industries such as chemical manufacturing, oil and gas, and food processing rely on these pipes to transport heated fluids or gases across their facilities. The insulating properties of the pipes help in maintaining the desired temperature of the transported medium, which is crucial for ensuring product quality and process efficiency. For instance, in the chemical industry, precise temperature control is essential for chemical reactions to occur as intended, and any deviation can lead to suboptimal results or even safety hazards. Similarly, in the food processing industry, maintaining the correct temperature is vital for preserving the quality and safety of food products. The use of heat preservation concrete pipes in these settings not only enhances operational efficiency but also contributes to energy conservation by reducing heat loss. Agricultural irrigation systems also benefit from the use of heat preservation concrete pipes, particularly in regions where temperature control is necessary for optimal crop growth. These pipes can be used to transport heated water to irrigation systems, ensuring that the water temperature is suitable for the crops being cultivated. This is especially important in colder climates, where cold water can shock plants and hinder their growth. By maintaining a consistent water temperature, farmers can improve crop yields and reduce the risk of damage caused by temperature fluctuations. Moreover, the durability and resistance to environmental factors offered by concrete pipes make them a reliable choice for agricultural applications, where they are often exposed to harsh conditions. Overall, the Global Heat Preservation Concrete Pipe Market serves a wide range of applications across different sectors, each benefiting from the energy-efficient and durable nature of these pipes. As the demand for sustainable and efficient solutions continues to grow, the market for heat preservation concrete pipes is expected to expand, offering innovative solutions to meet the diverse needs of municipal, industrial, and agricultural applications. The versatility and effectiveness of these pipes make them an essential component in efforts to improve energy efficiency and sustainability across various industries.

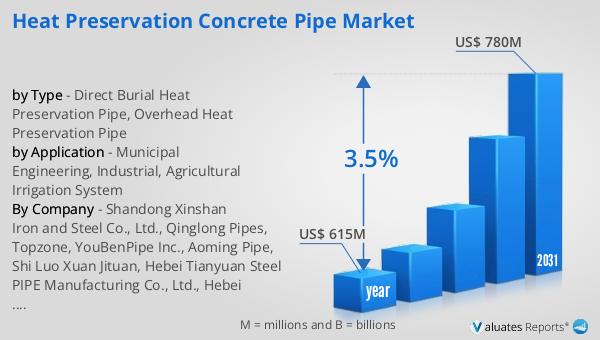

Global Heat Preservation Concrete Pipe Market Outlook:

In 2024, the global market for Heat Preservation Concrete Pipes was valued at approximately $615 million. This market is anticipated to grow steadily, reaching an estimated value of $780 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.5% over the forecast period. The steady increase in market size reflects the rising demand for energy-efficient and sustainable infrastructure solutions across various sectors. As industries and municipalities continue to prioritize energy conservation and cost reduction, the adoption of heat preservation concrete pipes is expected to rise. These pipes offer significant advantages in terms of minimizing heat loss and enhancing the efficiency of heating and cooling systems, making them an attractive option for a wide range of applications. The projected growth in the market underscores the importance of these pipes in supporting sustainable development efforts and meeting the evolving needs of industries and communities worldwide. As the market continues to expand, manufacturers and suppliers are likely to focus on innovation and product development to cater to the diverse requirements of different sectors, further driving the growth of the Global Heat Preservation Concrete Pipe Market.

| Report Metric | Details |

| Report Name | Heat Preservation Concrete Pipe Market |

| Accounted market size in year | US$ 615 million |

| Forecasted market size in 2031 | US$ 780 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Shandong Xinshan Iron and Steel Co., Ltd., Qinglong Pipes, Topzone, YouBenPipe Inc., Aoming Pipe, Shi Luo Xuan Jituan, Hebei Tianyuan Steel PIPE Manufacturing Co., Ltd., Hebei Zhuowei Steel Pipe Manufacturing, Cangzhou Hengtai Pipe Pipe Manufacturing, Hebei Longdu Pipeline Manufacturing Co. Ltd., Hebei Taofa Steel Pipe Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |