What is Global Heat-conducting Plastic Market?

The global heat-conducting plastic market is an innovative sector that focuses on the development and application of plastics capable of conducting heat. These specialized plastics are engineered to offer thermal conductivity while maintaining the inherent benefits of traditional plastics, such as lightweight, corrosion resistance, and ease of processing. The demand for heat-conducting plastics is driven by their ability to replace metals in various applications, offering a cost-effective and efficient alternative. These materials are particularly valuable in industries where heat dissipation is crucial, such as electronics, automotive, and aerospace. By providing effective thermal management, heat-conducting plastics help in enhancing the performance and longevity of electronic devices, improving fuel efficiency in vehicles, and ensuring safety in aerospace components. The market is witnessing growth due to technological advancements and increasing awareness of the benefits of these materials. As industries continue to seek sustainable and efficient solutions, the role of heat-conducting plastics is expected to expand, offering new opportunities for innovation and application across various sectors. The global heat-conducting plastic market is poised to play a significant role in the future of material science and engineering, contributing to the development of more efficient and sustainable products.

PPS, PBT, PC, PP, PPSU, Other in the Global Heat-conducting Plastic Market:

Polyphenylene sulfide (PPS) is a high-performance thermoplastic known for its exceptional thermal stability, chemical resistance, and mechanical properties. In the global heat-conducting plastic market, PPS is valued for its ability to withstand high temperatures and harsh environments, making it ideal for applications in the automotive and electronics industries. PPS is often used in components such as connectors, sensors, and housings, where heat resistance and dimensional stability are critical. Polybutylene terephthalate (PBT) is another important material in this market, offering excellent electrical insulation properties, low moisture absorption, and good mechanical strength. PBT is widely used in the electronics industry for connectors, switches, and other components that require reliable performance under thermal stress. Polycarbonate (PC) is a versatile thermoplastic known for its high impact resistance and optical clarity. In the heat-conducting plastic market, PC is used in applications where transparency and heat resistance are required, such as in lighting fixtures and electronic displays. Polypropylene (PP) is a widely used thermoplastic that offers a good balance of properties, including chemical resistance, low density, and ease of processing. In the context of heat-conducting plastics, PP is often modified with fillers to enhance its thermal conductivity, making it suitable for applications in automotive and consumer electronics. Polyphenylsulfone (PPSU) is a high-performance thermoplastic known for its excellent thermal stability, toughness, and resistance to hydrolysis. PPSU is used in demanding applications where heat resistance and durability are essential, such as in medical devices and aerospace components. Other materials in the global heat-conducting plastic market include various blends and composites that are engineered to meet specific performance requirements. These materials are often tailored to provide a balance of thermal conductivity, mechanical strength, and processability, enabling their use in a wide range of applications. The development of new materials and formulations continues to drive innovation in the heat-conducting plastic market, offering solutions that meet the evolving needs of industries seeking efficient and sustainable alternatives to traditional materials. As the demand for lightweight, high-performance materials grows, the role of these specialized plastics is expected to expand, providing new opportunities for application and development.

Electronics, Automotive, Aerospace, Healthcare, Other in the Global Heat-conducting Plastic Market:

The global heat-conducting plastic market finds extensive usage across various industries, each benefiting from the unique properties of these materials. In the electronics industry, heat-conducting plastics are used to manage thermal loads in devices such as smartphones, laptops, and LED lights. These materials help in dissipating heat efficiently, ensuring the longevity and performance of electronic components. By replacing metal parts with heat-conducting plastics, manufacturers can reduce weight and improve the design flexibility of electronic devices. In the automotive sector, heat-conducting plastics are used in components such as engine covers, battery housings, and lighting systems. These materials contribute to improved fuel efficiency by reducing the overall weight of vehicles while providing effective thermal management. The use of heat-conducting plastics in automotive applications also enhances safety and reliability by preventing overheating and ensuring optimal performance of critical components. In the aerospace industry, the demand for lightweight and high-performance materials is paramount. Heat-conducting plastics offer a solution by providing the necessary thermal management while reducing the weight of aircraft components. These materials are used in applications such as avionics, cabin interiors, and structural components, where heat resistance and durability are essential. In the healthcare sector, heat-conducting plastics are used in medical devices and equipment that require precise thermal management. These materials help in maintaining the performance and safety of devices such as diagnostic equipment, surgical instruments, and implants. The use of heat-conducting plastics in healthcare applications also contributes to the development of more efficient and reliable medical technologies. Other industries, such as consumer goods and industrial equipment, also benefit from the use of heat-conducting plastics. These materials provide solutions for thermal management in products ranging from household appliances to industrial machinery, offering improved performance and energy efficiency. As industries continue to seek innovative and sustainable solutions, the role of heat-conducting plastics is expected to grow, providing new opportunities for application and development across various sectors.

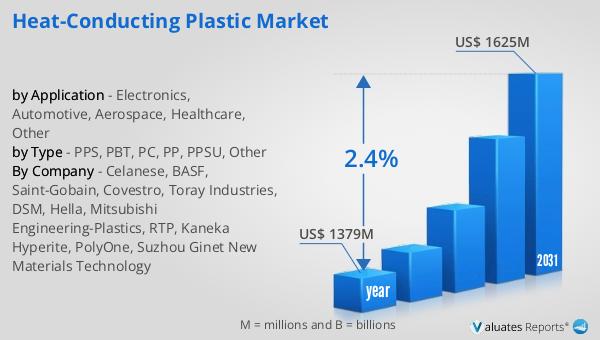

Global Heat-conducting Plastic Market Outlook:

The global market for heat-conducting plastics was valued at approximately $1,379 million in 2024. This market is anticipated to grow steadily, reaching an estimated size of $1,625 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.4% over the forecast period. The increasing demand for lightweight, efficient, and sustainable materials across various industries is a key driver of this market expansion. Heat-conducting plastics offer a unique combination of properties, including thermal conductivity, mechanical strength, and ease of processing, making them an attractive alternative to traditional materials such as metals. As industries continue to prioritize energy efficiency and sustainability, the adoption of heat-conducting plastics is expected to rise. The market's growth is also supported by ongoing advancements in material science and engineering, leading to the development of new formulations and applications. These innovations are enabling the use of heat-conducting plastics in a wider range of applications, from electronics and automotive to healthcare and aerospace. As the market continues to evolve, the role of heat-conducting plastics in providing efficient and sustainable solutions is expected to expand, offering new opportunities for growth and development.

| Report Metric | Details |

| Report Name | Heat-conducting Plastic Market |

| Accounted market size in year | US$ 1379 million |

| Forecasted market size in 2031 | US$ 1625 million |

| CAGR | 2.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Celanese, BASF, Saint-Gobain, Covestro, Toray Industries, DSM, Hella, Mitsubishi Engineering-Plastics, RTP, Kaneka Hyperite, PolyOne, Suzhou Ginet New Materials Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |