What is Global Glass-based Photomask Market?

The Global Glass-based Photomask Market is a crucial segment within the broader photomask industry, which plays a vital role in the manufacturing of electronic components. Photomasks are essential tools used in the photolithography process to transfer circuit patterns onto semiconductor wafers, flat panel displays, and other electronic devices. Glass-based photomasks, in particular, are made from high-quality glass substrates that provide the necessary transparency and durability required for precise patterning. These photomasks are integral to the production of semiconductors, which are the building blocks of modern electronic devices such as smartphones, computers, and televisions. The market for glass-based photomasks is driven by the increasing demand for advanced electronic devices, which require more sophisticated and miniaturized components. As technology continues to evolve, the need for high-precision photomasks becomes even more critical, fueling the growth of this market. Additionally, advancements in photomask technology, such as the development of more efficient and cost-effective manufacturing processes, are expected to further boost the market's expansion. The global glass-based photomask market is characterized by a competitive landscape with several key players striving to innovate and meet the growing demands of the electronics industry.

Synthetic Quartz Mask, Soda Lime Mask in the Global Glass-based Photomask Market:

In the realm of the Global Glass-based Photomask Market, two prominent types of masks are the Synthetic Quartz Mask and the Soda Lime Mask. Synthetic Quartz Masks are crafted from high-purity quartz glass, which offers exceptional thermal stability and optical clarity. These masks are particularly favored in applications that require high precision and durability, such as advanced semiconductor manufacturing. The superior properties of synthetic quartz, including its resistance to thermal expansion and its ability to withstand high-energy radiation, make it an ideal choice for photomasks used in cutting-edge technology production. On the other hand, Soda Lime Masks are made from soda lime glass, which is more cost-effective compared to synthetic quartz. While they may not offer the same level of thermal stability and optical performance as synthetic quartz masks, soda lime masks are still widely used in less demanding applications where cost considerations are paramount. The choice between synthetic quartz and soda lime masks often depends on the specific requirements of the manufacturing process, including factors such as resolution, durability, and budget constraints. In the semiconductor industry, where precision and reliability are critical, synthetic quartz masks are often preferred due to their superior performance characteristics. However, in applications where cost is a significant factor, soda lime masks provide a viable alternative without compromising too much on quality. The Global Glass-based Photomask Market is witnessing a growing demand for both types of masks, driven by the increasing complexity of electronic devices and the need for more sophisticated manufacturing processes. As technology continues to advance, the market is expected to see further innovations in photomask materials and designs, catering to the diverse needs of the electronics industry. The ongoing research and development efforts in this field aim to enhance the performance and cost-effectiveness of photomasks, ensuring that they can meet the ever-evolving demands of modern technology.

Semiconductor, Flat Panel Display, Others in the Global Glass-based Photomask Market:

The usage of Global Glass-based Photomask Market spans several critical areas, including semiconductors, flat panel displays, and other electronic applications. In the semiconductor industry, photomasks are indispensable tools used in the photolithography process to create intricate circuit patterns on silicon wafers. This process is fundamental to the production of integrated circuits, which are the core components of virtually all electronic devices. The precision and accuracy of glass-based photomasks are crucial in ensuring the quality and performance of semiconductors, which in turn affects the functionality of devices such as smartphones, computers, and automotive electronics. In the realm of flat panel displays, photomasks are used to pattern the thin film transistors and other components that make up the display matrix. The demand for high-resolution displays in televisions, monitors, and mobile devices has driven the need for advanced photomask technologies that can deliver the necessary precision and clarity. Glass-based photomasks provide the optical quality and durability required for these applications, enabling manufacturers to produce displays with superior image quality and performance. Beyond semiconductors and flat panel displays, glass-based photomasks find applications in other areas such as microelectromechanical systems (MEMS), optoelectronics, and printed circuit boards (PCBs). In MEMS, photomasks are used to create the intricate structures that form the basis of these miniature devices, which are used in a wide range of applications from sensors to actuators. In optoelectronics, photomasks are essential for the fabrication of components such as light-emitting diodes (LEDs) and laser diodes, which are used in lighting, communication, and display technologies. In the production of PCBs, photomasks are used to define the circuit patterns that connect electronic components, ensuring the functionality and reliability of the final product. The versatility and precision of glass-based photomasks make them a critical component in the manufacturing processes of various electronic devices, driving their demand across multiple industries.

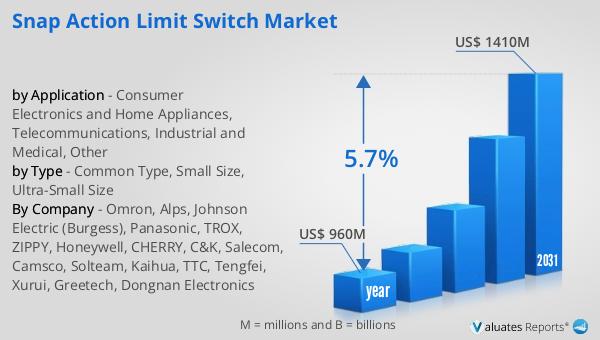

Global Glass-based Photomask Market Outlook:

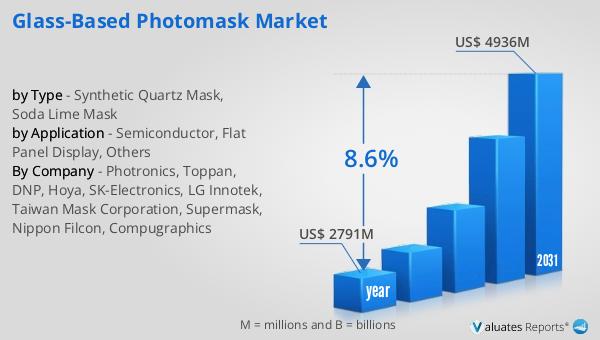

The outlook for the Global Glass-based Photomask Market is promising, with significant growth projected over the coming years. In 2024, the market was valued at approximately US$ 2,791 million, and it is anticipated to expand to a revised size of US$ 4,936 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.6% during the forecast period. This robust growth can be attributed to several factors, including the increasing demand for advanced electronic devices, the continuous evolution of semiconductor technology, and the rising adoption of high-resolution displays. As consumer electronics become more sophisticated and integrated into everyday life, the need for high-precision photomasks becomes even more critical. Additionally, the ongoing advancements in photomask manufacturing processes, such as the development of more efficient and cost-effective techniques, are expected to further drive market growth. The competitive landscape of the glass-based photomask market is characterized by the presence of several key players who are actively investing in research and development to innovate and meet the growing demands of the electronics industry. These companies are focused on enhancing the performance and cost-effectiveness of their photomask offerings, ensuring that they can cater to the diverse needs of their customers. As the market continues to evolve, it is expected to witness further innovations in photomask materials and designs, catering to the diverse needs of the electronics industry.

| Report Metric | Details |

| Report Name | Glass-based Photomask Market |

| Accounted market size in year | US$ 2791 million |

| Forecasted market size in 2031 | US$ 4936 million |

| CAGR | 8.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Photronics, Toppan, DNP, Hoya, SK-Electronics, LG Innotek, Taiwan Mask Corporation, Supermask, Nippon Filcon, Compugraphics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |