What is Global Food Machinery Grease Market?

The Global Food Machinery Grease Market is a specialized segment within the broader industrial lubricants industry, focusing on the production and distribution of grease specifically designed for food processing equipment. This market is crucial because it ensures that machinery used in food production operates smoothly and efficiently, minimizing downtime and maintenance costs. Food machinery grease is formulated to meet stringent safety and hygiene standards, as it comes into contact with food products. It must be non-toxic, odorless, and tasteless, ensuring that it does not contaminate the food being processed. The demand for food machinery grease is driven by the growing food and beverage industry, which requires reliable and efficient machinery to meet increasing consumer demands. Additionally, the market is influenced by regulatory requirements that mandate the use of food-grade lubricants in food processing facilities. As a result, manufacturers are continually innovating to develop greases that offer superior performance while adhering to safety standards. The market is characterized by a diverse range of products, catering to different types of machinery and processing environments, making it a dynamic and essential component of the global food production ecosystem.

H1, H3, 3H in the Global Food Machinery Grease Market:

In the context of the Global Food Machinery Grease Market, H1, H3, and 3H refer to different types of greases used in various applications within the food processing industry. H1 greases are designed for incidental food contact, meaning they can be used in areas where there is a possibility of the grease coming into contact with food. These greases are formulated to be non-toxic and safe for consumption in small quantities, adhering to strict regulatory standards. They are commonly used in equipment such as mixers, conveyors, and packaging machines, where the risk of incidental contact is higher. H3 greases, on the other hand, are used in applications where there is no possibility of food contact. These greases are typically used in equipment that does not come into direct contact with food, such as motors and gearboxes. They are formulated to provide excellent lubrication and protection against wear and tear, ensuring the longevity and efficiency of the machinery. 3H greases are used in applications where direct food contact is unavoidable. These greases are formulated to be completely safe for consumption and are used in equipment such as slicers and grinders, where the grease may come into direct contact with the food being processed. The development and use of these different types of greases are driven by the need to ensure food safety and hygiene while maintaining the efficiency and reliability of food processing equipment. Manufacturers in the Global Food Machinery Grease Market are continually innovating to develop greases that offer superior performance while adhering to safety standards. This involves the use of advanced formulations and additives that enhance the lubricating properties of the grease while ensuring that it remains safe for use in food processing environments. The market is characterized by a diverse range of products, catering to different types of machinery and processing environments. This diversity is driven by the varying needs of different segments within the food processing industry, each of which requires specific types of greases to ensure optimal performance. For example, the meat processing industry requires greases that can withstand high temperatures and heavy loads, while the confectionery industry requires greases that are resistant to sugar and other sticky substances. The Global Food Machinery Grease Market is also influenced by regulatory requirements that mandate the use of food-grade lubricants in food processing facilities. These regulations are designed to ensure that the greases used in food processing equipment do not pose a risk to consumer health. As a result, manufacturers are required to adhere to strict standards when developing and producing food machinery greases. This has led to the development of a wide range of greases that are specifically designed to meet the needs of different segments within the food processing industry. The market is also characterized by a high level of competition, with numerous manufacturers vying for market share. This competition drives innovation and ensures that manufacturers are continually developing new and improved greases that offer superior performance and safety. The Global Food Machinery Grease Market is a dynamic and essential component of the global food production ecosystem, providing the lubrication and protection needed to ensure the efficient and reliable operation of food processing equipment.

Meat Processing Machinery, Fruit and Vegetable Machinery, Confectionery and Chocolate Machinery, Alcoholic and Non-alcoholic Beverage Machinery, Animal Food Machinery, Others in the Global Food Machinery Grease Market:

The Global Food Machinery Grease Market plays a crucial role in various sectors of the food processing industry, including meat processing machinery, fruit and vegetable machinery, confectionery and chocolate machinery, alcoholic and non-alcoholic beverage machinery, animal food machinery, and others. In the meat processing sector, machinery such as slicers, grinders, and mixers require greases that can withstand high temperatures and heavy loads. These greases ensure that the equipment operates smoothly and efficiently, minimizing downtime and maintenance costs. In the fruit and vegetable processing sector, machinery such as peelers, cutters, and juicers require greases that are resistant to water and other liquids. These greases ensure that the equipment operates efficiently, even in wet environments, and helps to prevent corrosion and wear. In the confectionery and chocolate processing sector, machinery such as mixers, extruders, and enrobers require greases that are resistant to sugar and other sticky substances. These greases ensure that the equipment operates smoothly and efficiently, preventing the buildup of sticky residues that can cause equipment malfunctions. In the alcoholic and non-alcoholic beverage processing sector, machinery such as bottling lines, fillers, and cappers require greases that are resistant to liquids and provide excellent lubrication. These greases ensure that the equipment operates smoothly and efficiently, minimizing downtime and maintenance costs. In the animal food processing sector, machinery such as mixers, grinders, and pelletizers require greases that can withstand high temperatures and heavy loads. These greases ensure that the equipment operates smoothly and efficiently, minimizing downtime and maintenance costs. In other sectors of the food processing industry, such as bakery and dairy processing, machinery requires greases that are resistant to high temperatures and provide excellent lubrication. These greases ensure that the equipment operates smoothly and efficiently, minimizing downtime and maintenance costs. The Global Food Machinery Grease Market is characterized by a diverse range of products, catering to the specific needs of different sectors within the food processing industry. This diversity is driven by the varying requirements of different types of machinery and processing environments, each of which requires specific types of greases to ensure optimal performance. Manufacturers in the Global Food Machinery Grease Market are continually innovating to develop greases that offer superior performance while adhering to safety standards. This involves the use of advanced formulations and additives that enhance the lubricating properties of the grease while ensuring that it remains safe for use in food processing environments. The market is also influenced by regulatory requirements that mandate the use of food-grade lubricants in food processing facilities. These regulations are designed to ensure that the greases used in food processing equipment do not pose a risk to consumer health. As a result, manufacturers are required to adhere to strict standards when developing and producing food machinery greases. This has led to the development of a wide range of greases that are specifically designed to meet the needs of different sectors within the food processing industry. The Global Food Machinery Grease Market is a dynamic and essential component of the global food production ecosystem, providing the lubrication and protection needed to ensure the efficient and reliable operation of food processing equipment.

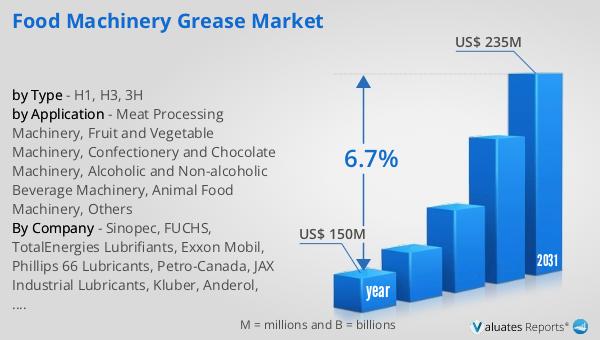

Global Food Machinery Grease Market Outlook:

In 2024, the global market for Food Machinery Grease was valued at approximately $150 million. Looking ahead, this market is anticipated to expand significantly, reaching an estimated value of $235 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.7% over the forecast period. The increasing demand for food machinery grease is driven by the expanding food and beverage industry, which requires reliable and efficient machinery to meet growing consumer demands. As the industry continues to evolve, there is a heightened focus on ensuring that machinery operates smoothly and efficiently, minimizing downtime and maintenance costs. This has led to an increased demand for high-quality food machinery greases that offer superior performance and adhere to stringent safety and hygiene standards. Additionally, regulatory requirements mandating the use of food-grade lubricants in food processing facilities have further fueled the demand for food machinery greases. Manufacturers are continually innovating to develop greases that offer enhanced lubricating properties while ensuring safety and compliance with regulatory standards. The Global Food Machinery Grease Market is characterized by a diverse range of products, catering to different types of machinery and processing environments. This diversity is driven by the varying needs of different segments within the food processing industry, each of which requires specific types of greases to ensure optimal performance. As a result, the market is expected to continue its growth trajectory, driven by the increasing demand for food machinery greases that offer superior performance and safety.

| Report Metric | Details |

| Report Name | Food Machinery Grease Market |

| Accounted market size in year | US$ 150 million |

| Forecasted market size in 2031 | US$ 235 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sinopec, FUCHS, TotalEnergies Lubrifiants, Exxon Mobil, Phillips 66 Lubricants, Petro-Canada, JAX Industrial Lubricants, Kluber, Anderol, Jet-Lube, SKF, Interflon, ITW Pro Brands, Dupont, Henkel, SUMICO, OKS Spezialschmierstoffe, BECHEM, Lubrication Engineers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |