What is Global Flame Retardant Regenerated Cellulose Fibre Market?

The Global Flame Retardant Regenerated Cellulose Fibre Market is a specialized segment within the textile industry that focuses on producing fibers with enhanced fire-resistant properties. These fibers are derived from regenerated cellulose, a natural polymer obtained from wood pulp or cotton linters, and are treated with flame retardant chemicals to reduce their flammability. The demand for such fibers is driven by the increasing need for fire safety in various applications, including clothing, home textiles, and industrial uses. As awareness about fire hazards grows, industries are seeking materials that not only meet safety standards but also offer comfort and sustainability. Flame retardant regenerated cellulose fibers provide a balance between these requirements, making them an attractive choice for manufacturers and consumers alike. The market is characterized by continuous innovation, with companies investing in research and development to improve the efficacy and environmental impact of these fibers. As regulations around fire safety become more stringent globally, the market for flame retardant regenerated cellulose fibers is expected to expand, offering new opportunities for growth and development in the textile sector.

Phosphorus Type, Silicon Nitrogen Type, Others in the Global Flame Retardant Regenerated Cellulose Fibre Market:

In the Global Flame Retardant Regenerated Cellulose Fibre Market, different types of flame retardant treatments are used to enhance the fire-resistant properties of cellulose fibers. Among these, the Phosphorus Type, Silicon Nitrogen Type, and others play significant roles. The Phosphorus Type involves the incorporation of phosphorus-based compounds into the cellulose fibers. These compounds work by promoting char formation and reducing the release of flammable gases during combustion. Phosphorus-based flame retardants are known for their effectiveness and are widely used in various applications due to their ability to provide durable flame resistance without significantly affecting the physical properties of the fibers. On the other hand, the Silicon Nitrogen Type involves the use of silicon and nitrogen-containing compounds. These compounds create a protective barrier on the fiber surface, which helps in insulating the material from heat and oxygen, thereby slowing down the combustion process. Silicon Nitrogen flame retardants are valued for their environmental friendliness and low toxicity, making them a preferred choice for applications where human contact is frequent, such as clothing and home textiles. Besides these, there are other types of flame retardant treatments that may involve the use of halogenated compounds, mineral-based additives, or a combination of different chemical treatments. Each type of flame retardant offers unique benefits and limitations, and the choice of treatment often depends on the specific requirements of the end-use application. For instance, halogenated flame retardants are highly effective but may pose environmental and health concerns, leading to a decline in their usage in favor of more sustainable alternatives. Mineral-based additives, such as aluminum hydroxide or magnesium hydroxide, are non-toxic and environmentally benign, but they may require higher loading levels to achieve the desired flame retardancy, which can affect the mechanical properties of the fibers. The development of flame retardant regenerated cellulose fibers is a complex process that involves balancing the trade-offs between fire resistance, environmental impact, cost, and performance. Manufacturers are continuously exploring new formulations and technologies to enhance the flame retardant properties of cellulose fibers while minimizing any adverse effects on the environment and human health. This ongoing innovation is crucial for meeting the evolving demands of the market and ensuring compliance with increasingly stringent fire safety regulations. As the Global Flame Retardant Regenerated Cellulose Fibre Market continues to grow, the diversity of flame retardant types and their applications is expected to expand, offering new opportunities for innovation and development in the textile industry.

Fireproof Clothing, Home Textiles, Automotive, Aerospace, Public Interiors, Others in the Global Flame Retardant Regenerated Cellulose Fibre Market:

The Global Flame Retardant Regenerated Cellulose Fibre Market finds its applications across various sectors, each with specific requirements for fire safety and performance. In the realm of fireproof clothing, these fibers are used to manufacture garments that provide protection against fire hazards for workers in industries such as firefighting, oil and gas, and electrical utilities. The inherent flame-resistant properties of these fibers, combined with their comfort and breathability, make them ideal for protective clothing that needs to be worn for extended periods. In home textiles, flame retardant regenerated cellulose fibers are used in products such as curtains, upholstery, and bedding. These applications require materials that not only meet fire safety standards but also offer aesthetic appeal and comfort. The use of flame retardant fibers in home textiles helps in reducing the risk of fire-related accidents in residential settings, providing peace of mind to consumers. In the automotive industry, these fibers are used in the interior components of vehicles, such as seat covers, headliners, and door panels. The use of flame retardant materials in automotive interiors is crucial for enhancing passenger safety and meeting regulatory requirements. Similarly, in the aerospace sector, flame retardant regenerated cellulose fibers are used in the manufacturing of aircraft interiors, including seat covers, carpets, and wall panels. The stringent fire safety standards in the aerospace industry necessitate the use of materials that can withstand high temperatures and prevent the spread of flames. Public interiors, such as those in theaters, auditoriums, and public transportation, also benefit from the use of flame retardant regenerated cellulose fibers. These environments require materials that can provide fire safety without compromising on aesthetics and durability. In addition to these specific applications, flame retardant regenerated cellulose fibers are also used in other areas where fire safety is a concern, such as in the production of tents, awnings, and industrial fabrics. The versatility and effectiveness of these fibers make them a valuable component in a wide range of products, contributing to enhanced safety and performance across various industries. As the demand for fire-safe materials continues to grow, the Global Flame Retardant Regenerated Cellulose Fibre Market is poised to play a crucial role in meeting the needs of diverse applications, driving innovation and development in the textile sector.

Global Flame Retardant Regenerated Cellulose Fibre Market Outlook:

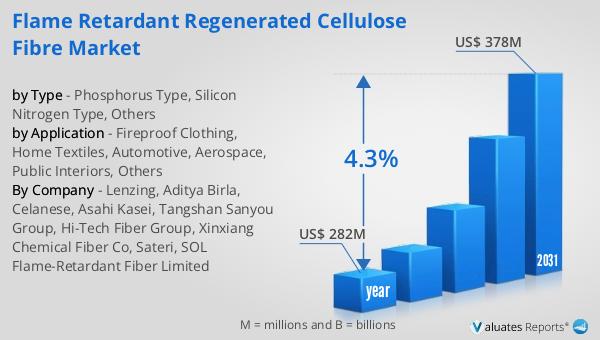

The global market for Flame Retardant Regenerated Cellulose Fibre was valued at $282 million in 2024 and is anticipated to grow to a revised size of $378 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. Lenzing, Tangshan Sanyou Group, and HiTech Fiber Group are the leading manufacturers in this market, collectively accounting for over 55% of the total market share. Geographically, the Asia Pacific region emerges as the largest producer of flame retardant regenerated cellulose fiber, holding a share of over 45%, followed by Europe and North America. This growth is driven by the increasing demand for fire-safe materials across various industries, including textiles, automotive, and aerospace. The market's expansion is further supported by the rising awareness of fire safety regulations and the need for sustainable and environmentally friendly materials. As the market continues to evolve, manufacturers are focusing on innovation and the development of new flame retardant technologies to meet the diverse needs of consumers and industries. The competitive landscape is characterized by strategic collaborations, mergers, and acquisitions, as companies seek to strengthen their market position and expand their product offerings. With the growing emphasis on safety and sustainability, the Global Flame Retardant Regenerated Cellulose Fibre Market is set to witness significant growth and transformation in the coming years.

| Report Metric | Details |

| Report Name | Flame Retardant Regenerated Cellulose Fibre Market |

| Accounted market size in year | US$ 282 million |

| Forecasted market size in 2031 | US$ 378 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lenzing, Aditya Birla, Celanese, Asahi Kasei, Tangshan Sanyou Group, Hi-Tech Fiber Group, Xinxiang Chemical Fiber Co, Sateri, SOL Flame-Retardant Fiber Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |