What is Global ePTFE Tubing Market?

The Global ePTFE Tubing Market is a specialized segment within the broader tubing industry, focusing on the production and distribution of expanded polytetrafluoroethylene (ePTFE) tubing. ePTFE is a unique material known for its exceptional properties, including high chemical resistance, low friction, and excellent thermal stability. These characteristics make it an ideal choice for various applications across different industries. The market for ePTFE tubing is driven by its demand in sectors such as medical, industrial, and other specialized fields where its unique properties are highly valued. The tubing is manufactured through a specialized process that expands and orients PTFE, resulting in a product that is both soft and flexible, yet incredibly durable. This makes ePTFE tubing suitable for use in environments where traditional materials might fail. As industries continue to seek materials that offer superior performance and reliability, the demand for ePTFE tubing is expected to grow, driven by its versatility and the increasing complexity of applications in which it is used. The market is characterized by continuous innovation and development, as manufacturers strive to enhance the properties of ePTFE tubing to meet the evolving needs of their customers.

≤0.5mm, >0.5mm in the Global ePTFE Tubing Market:

In the Global ePTFE Tubing Market, the size of the tubing plays a crucial role in determining its application and suitability for various uses. Tubing with a diameter of ≤0.5mm is typically used in applications that require precision and flexibility. This size is particularly favored in the medical industry, where it is used in minimally invasive surgical procedures and as part of medical devices that require small, flexible components. The small diameter allows for easy integration into complex systems and provides the necessary flexibility without compromising strength. On the other hand, tubing with a diameter of >0.5mm is often used in industrial applications where durability and robustness are more critical. This size is suitable for use in environments where the tubing may be exposed to harsh chemicals or extreme temperatures, as it can withstand such conditions without degrading. The larger diameter also allows for a higher flow rate, making it ideal for applications that require efficient fluid transfer. In both cases, the unique properties of ePTFE, such as its chemical resistance and thermal stability, make it an excellent choice for a wide range of applications. The market for ePTFE tubing is driven by the need for materials that can perform reliably in demanding conditions, and the availability of tubing in different sizes allows manufacturers to cater to the specific needs of their customers. As industries continue to evolve and the demand for high-performance materials increases, the market for ePTFE tubing is expected to grow, with manufacturers focusing on developing new products that offer enhanced performance and reliability.

Industry, Medical, Other in the Global ePTFE Tubing Market:

The Global ePTFE Tubing Market finds its usage across various sectors, including industry, medical, and other specialized fields. In the industrial sector, ePTFE tubing is valued for its durability and resistance to harsh chemicals and extreme temperatures. It is commonly used in chemical processing, where it serves as a conduit for transporting aggressive chemicals without the risk of degradation. The tubing's low friction and non-stick properties also make it ideal for use in applications where material build-up could be an issue, such as in the food processing industry. In the medical field, ePTFE tubing is used in a variety of applications, including as part of medical devices and in surgical procedures. Its flexibility and biocompatibility make it an ideal choice for use in minimally invasive surgeries, where it can be used to navigate complex anatomical structures without causing damage. The tubing is also used in the manufacture of catheters and other medical devices that require a high degree of precision and reliability. In other specialized fields, ePTFE tubing is used in applications that require a combination of flexibility, durability, and chemical resistance. This includes use in the aerospace industry, where it is used in fuel and hydraulic systems, and in the electronics industry, where it is used as insulation for wiring and cables. The versatility of ePTFE tubing makes it a valuable material in a wide range of applications, and its unique properties ensure that it can perform reliably in even the most demanding conditions.

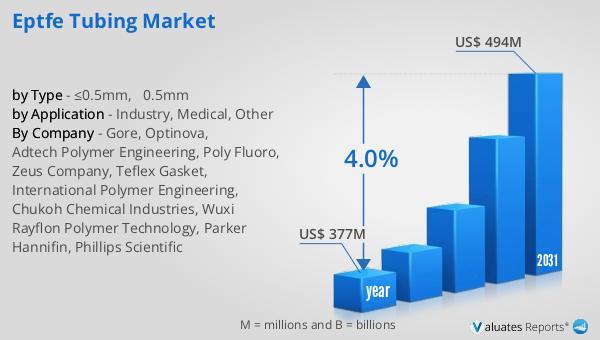

Global ePTFE Tubing Market Outlook:

The global market for ePTFE Tubing was valued at $377 million in 2024 and is anticipated to grow to a revised size of $494 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period. This growth is driven by the increasing demand for high-performance materials in various industries, as well as the unique properties of ePTFE tubing that make it an ideal choice for a wide range of applications. ePTFE tubing is produced through a specialized extrusion process that expands and orients the PTFE, resulting in a product that is both soft and flexible. This makes it suitable for use in applications where traditional materials might fail, such as in environments with harsh chemicals or extreme temperatures. The market is characterized by continuous innovation and development, as manufacturers strive to enhance the properties of ePTFE tubing to meet the evolving needs of their customers. As industries continue to seek materials that offer superior performance and reliability, the demand for ePTFE tubing is expected to grow, driven by its versatility and the increasing complexity of applications in which it is used. The market outlook for ePTFE tubing is positive, with steady growth expected over the forecast period as more industries recognize the benefits of this unique material.

| Report Metric | Details |

| Report Name | ePTFE Tubing Market |

| Accounted market size in year | US$ 377 million |

| Forecasted market size in 2031 | US$ 494 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gore, Optinova, Adtech Polymer Engineering, Poly Fluoro, Zeus Company, Teflex Gasket, International Polymer Engineering, Chukoh Chemical Industries, Wuxi Rayflon Polymer Technology, Parker Hannifin, Phillips Scientific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |