What is Global Drug Functional Film Coating Market?

The Global Drug Functional Film Coating Market is a specialized segment within the pharmaceutical industry that focuses on the application of thin, protective layers on drug tablets and capsules. These coatings serve multiple purposes, such as enhancing the stability of the drug, controlling the release of the active ingredients, and improving the overall appearance and taste of the medication. The market is driven by the increasing demand for advanced drug delivery systems that can improve patient compliance and therapeutic outcomes. Functional film coatings are essential in ensuring that drugs are delivered effectively and safely to patients, as they can protect the drug from environmental factors like moisture and light, which can degrade the active ingredients. Additionally, these coatings can be tailored to provide specific release profiles, such as immediate, delayed, or sustained release, depending on the therapeutic needs. The market is characterized by continuous innovation and development, with pharmaceutical companies investing in research to create more efficient and patient-friendly drug delivery systems. As the global population ages and the prevalence of chronic diseases rises, the demand for functional film coatings is expected to grow, making it a vital component of the pharmaceutical manufacturing process.

Cellulose Polymer, Vinyl Derivatives, Acrylic Polymer, Others in the Global Drug Functional Film Coating Market:

Cellulose polymers, vinyl derivatives, acrylic polymers, and other materials play a crucial role in the Global Drug Functional Film Coating Market, each offering unique properties that cater to different pharmaceutical needs. Cellulose polymers, such as hydroxypropyl methylcellulose (HPMC) and ethylcellulose, are widely used due to their versatility and safety profile. They are known for their excellent film-forming capabilities, which make them ideal for creating protective coatings that enhance the stability and shelf life of drugs. These polymers can be used to produce both immediate and controlled-release formulations, providing flexibility in drug delivery. Vinyl derivatives, such as polyvinyl alcohol (PVA) and polyvinyl acetate, are valued for their strong adhesive properties and resistance to moisture. These characteristics make them suitable for coatings that require a high degree of protection against environmental factors. Vinyl derivatives are often used in combination with other polymers to achieve the desired coating performance. Acrylic polymers, including methacrylic acid copolymers, are known for their ability to form films with excellent mechanical strength and resistance to gastric fluids. This makes them particularly useful for enteric coatings, which protect drugs from being released in the acidic environment of the stomach, ensuring that they reach the intestine where absorption occurs. Acrylic polymers can also be used to create sustained-release formulations, allowing for a gradual release of the active ingredient over time. Other materials used in drug functional film coatings include natural polymers like alginates and chitosan, as well as synthetic options like polyethylene glycol (PEG). These materials are selected based on their compatibility with the active pharmaceutical ingredient (API) and the desired release profile. The choice of coating material is critical, as it can significantly impact the drug's efficacy, safety, and patient acceptability. Manufacturers must carefully consider factors such as solubility, permeability, and stability when selecting a coating material to ensure optimal performance. The development of new and improved coating materials is an ongoing area of research, with the aim of enhancing drug delivery and patient outcomes. As the pharmaceutical industry continues to evolve, the demand for innovative and effective film coating materials is expected to grow, driving advancements in this essential aspect of drug formulation.

OTC, Prescription Drugs in the Global Drug Functional Film Coating Market:

The Global Drug Functional Film Coating Market plays a significant role in the formulation of both over-the-counter (OTC) and prescription drugs, enhancing their effectiveness and patient compliance. In the realm of OTC drugs, functional film coatings are used to improve the appearance, taste, and swallowability of medications, making them more appealing to consumers. These coatings can mask the unpleasant taste of certain active ingredients, ensuring that patients are more likely to adhere to their medication regimen. Additionally, film coatings can provide a protective barrier that enhances the stability and shelf life of OTC drugs, ensuring that they remain effective throughout their intended use. For prescription drugs, functional film coatings are essential in achieving specific therapeutic outcomes. These coatings can be engineered to control the release of the active ingredient, allowing for immediate, delayed, or sustained release profiles. This is particularly important for medications that require precise dosing and timing to achieve optimal therapeutic effects. For example, sustained-release formulations can provide a steady release of the drug over an extended period, reducing the need for frequent dosing and improving patient compliance. Enteric coatings, a type of functional film coating, are used to protect drugs from the acidic environment of the stomach, ensuring that they are released in the intestine where absorption occurs. This is crucial for drugs that can be degraded by stomach acid or cause irritation to the gastric lining. The use of functional film coatings in prescription drugs also extends to the development of combination therapies, where multiple active ingredients are combined in a single dosage form. Coatings can be used to separate these ingredients, preventing interactions that could compromise the drug's efficacy or safety. The versatility and adaptability of functional film coatings make them an indispensable tool in the pharmaceutical industry, enabling the development of innovative drug delivery systems that meet the diverse needs of patients. As the demand for personalized medicine and advanced drug delivery systems continues to grow, the role of functional film coatings in both OTC and prescription drugs is expected to expand, driving further advancements in this critical area of pharmaceutical formulation.

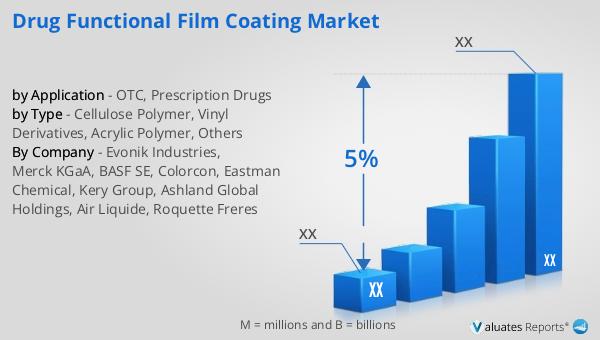

Global Drug Functional Film Coating Market Outlook:

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, demonstrating a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth reflects the increasing demand for pharmaceutical products driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development technologies. In comparison, the chemical drug market has also shown significant growth, with its value rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This increase highlights the ongoing importance of chemical drugs within the broader pharmaceutical landscape, as they continue to play a crucial role in the treatment and management of various health conditions. The growth in both the pharmaceutical and chemical drug markets underscores the need for innovative solutions, such as functional film coatings, to enhance drug delivery and patient outcomes. As the industry continues to evolve, the demand for advanced drug delivery systems and formulations is expected to drive further growth and development in the Global Drug Functional Film Coating Market. This market outlook emphasizes the critical role that functional film coatings play in the pharmaceutical industry, as they contribute to the effectiveness, safety, and patient acceptability of both OTC and prescription drugs.

| Report Metric | Details |

| Report Name | Drug Functional Film Coating Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Evonik Industries, Merck KGaA, BASF SE, Colorcon, Eastman Chemical, Kery Group, Ashland Global Holdings, Air Liquide, Roquette Freres |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |