What is Global Diaphragm Valves for Pharmaceutical Process Market?

The Global Diaphragm Valves for Pharmaceutical Process Market is a specialized segment within the broader industrial valves market, focusing on the unique needs of the pharmaceutical industry. Diaphragm valves are crucial in pharmaceutical processes due to their ability to provide a contamination-free environment, which is essential for maintaining the purity and integrity of pharmaceutical products. These valves are designed to control the flow of liquids and gases with precision, ensuring that the stringent hygiene standards required in pharmaceutical manufacturing are met. They are particularly valued for their ability to handle corrosive and abrasive fluids, which are common in pharmaceutical processes. The market for these valves is driven by the increasing demand for pharmaceuticals globally, as well as the need for advanced manufacturing processes that comply with regulatory standards. As pharmaceutical companies continue to innovate and expand their production capabilities, the demand for reliable and efficient diaphragm valves is expected to grow, making this market a critical component of the pharmaceutical supply chain.

Stainless Steel, Plastic, Others in the Global Diaphragm Valves for Pharmaceutical Process Market:

In the Global Diaphragm Valves for Pharmaceutical Process Market, materials play a crucial role in determining the performance and suitability of the valves for specific applications. Stainless steel is the most commonly used material, accounting for over 60% of the market share. This is due to its excellent corrosion resistance, durability, and ability to withstand high temperatures, making it ideal for the demanding environments of pharmaceutical manufacturing. Stainless steel diaphragm valves are often used in applications where hygiene and cleanliness are paramount, as they can be easily sterilized and do not react with the chemicals used in pharmaceutical processes. Plastic diaphragm valves, on the other hand, offer a cost-effective alternative to stainless steel. They are lightweight, resistant to corrosion, and suitable for applications where the operating conditions are less demanding. Plastics such as polypropylene and PVDF are commonly used in the construction of these valves, providing a balance between performance and cost. However, plastic valves may not be suitable for high-temperature applications or those involving aggressive chemicals. Other materials used in the construction of diaphragm valves include elastomers and composites, which offer unique properties such as flexibility and chemical resistance. These materials are often used in specialized applications where traditional materials may not perform adequately. The choice of material for diaphragm valves is influenced by several factors, including the nature of the fluid being handled, the operating conditions, and the specific requirements of the pharmaceutical process. As the pharmaceutical industry continues to evolve, the demand for diaphragm valves made from advanced materials is expected to increase, driving innovation and development in this market segment.

Pharmaceutical Water System, CIP and SIP System, Filtration and Filling, Others in the Global Diaphragm Valves for Pharmaceutical Process Market:

The usage of Global Diaphragm Valves for Pharmaceutical Process Market spans several critical areas within the pharmaceutical industry, each with its unique requirements and challenges. In pharmaceutical water systems, diaphragm valves are essential for ensuring the purity and quality of water used in drug manufacturing. These systems require valves that can handle high-purity water without introducing contaminants, making diaphragm valves an ideal choice due to their hygienic design and ability to prevent cross-contamination. In Clean-in-Place (CIP) and Steam-in-Place (SIP) systems, diaphragm valves play a crucial role in maintaining the cleanliness and sterility of pharmaceutical equipment. These systems require valves that can withstand repeated exposure to cleaning agents and high-temperature steam, ensuring that the equipment remains free from microbial contamination. Diaphragm valves are well-suited for these applications due to their robust construction and ability to provide a tight seal, preventing leaks and ensuring the integrity of the cleaning process. In filtration and filling processes, diaphragm valves are used to control the flow of liquids and gases with precision, ensuring that the correct volumes are delivered without compromising the quality of the product. These processes require valves that can handle a wide range of pressures and flow rates, making diaphragm valves an ideal choice due to their versatility and reliability. Other applications of diaphragm valves in the pharmaceutical industry include the handling of aggressive chemicals and the control of critical process parameters, where their ability to provide precise control and maintain a contamination-free environment is essential. As the pharmaceutical industry continues to grow and evolve, the demand for diaphragm valves in these and other applications is expected to increase, driving innovation and development in this market segment.

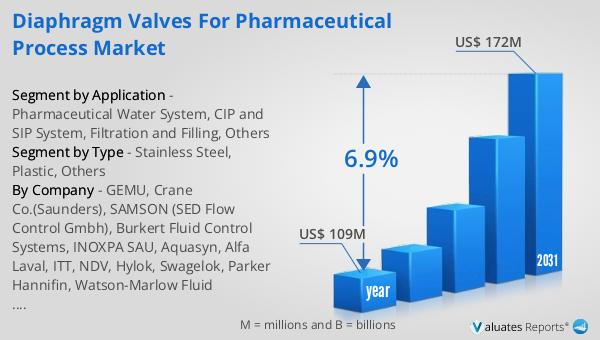

Global Diaphragm Valves for Pharmaceutical Process Market Outlook:

The global market for Diaphragm Valves for Pharmaceutical Process was valued at $109 million in 2024 and is anticipated to grow to $172 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.9% over the forecast period. Among the key players in this market, GEMU stands out, holding approximately 20% of the market share. Other significant players include Crane Co., Saunders, SAMSON, SED Flow Control GmbH, and Burkert Fluid Control Systems. In terms of materials, stainless steel dominates the market, accounting for over 60% of the total share. This preference is due to stainless steel's superior properties, such as corrosion resistance and durability, which are crucial for pharmaceutical applications. When it comes to applications, the pharmaceutical water system segment is the largest, holding more than 30% of the market share. This segment's prominence underscores the critical role of diaphragm valves in maintaining the purity and quality of water used in pharmaceutical manufacturing. As the market continues to expand, driven by the increasing demand for pharmaceuticals and the need for advanced manufacturing processes, diaphragm valves are expected to remain a vital component of the pharmaceutical supply chain.

| Report Metric | Details |

| Report Name | Diaphragm Valves for Pharmaceutical Process Market |

| Accounted market size in year | US$ 109 million |

| Forecasted market size in 2031 | US$ 172 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | GEMU, Crane Co.(Saunders), SAMSON (SED Flow Control Gmbh), Burkert Fluid Control Systems, INOXPA SAU, Aquasyn, Alfa Laval, ITT, NDV, Hylok, Swagelok, Parker Hannifin, Watson-Marlow Fluid Technology Group (ASEPCO), Steel & O'Brien, Shanghai REMY, Rodaff Fluid Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |