What is Global CoPolyester Hot Melt Adhesives Market?

The Global CoPolyester Hot Melt Adhesives Market is a dynamic and evolving sector within the broader adhesives industry. CoPolyester hot melt adhesives are a type of thermoplastic adhesive that becomes tacky upon heating and solidifies upon cooling, providing a strong bond. These adhesives are particularly valued for their versatility, as they can be used in a wide range of applications across various industries. They are known for their excellent adhesion properties, resistance to chemicals and moisture, and ability to bond with different substrates, including plastics, metals, and textiles. The market for these adhesives is driven by the increasing demand for sustainable and eco-friendly products, as CoPolyester adhesives are often more environmentally friendly compared to traditional solvent-based adhesives. Additionally, the growing emphasis on lightweight and durable materials in industries such as automotive and packaging further propels the demand for CoPolyester hot melt adhesives. As industries continue to innovate and seek more efficient bonding solutions, the Global CoPolyester Hot Melt Adhesives Market is expected to witness significant growth, adapting to the changing needs of manufacturers and consumers alike.

Granulat, Power in the Global CoPolyester Hot Melt Adhesives Market:

Granulat and powder forms of CoPolyester hot melt adhesives play a crucial role in the Global CoPolyester Hot Melt Adhesives Market, offering unique advantages and applications. Granulat, or granular form, is often preferred for its ease of handling and precise application. These granules can be easily melted and applied using standard hot melt equipment, making them ideal for automated production lines. The granular form ensures consistent melting and bonding, which is essential for maintaining the quality and reliability of the adhesive bond. This form is particularly popular in industries where precision and efficiency are paramount, such as in the automotive and electronics sectors. On the other hand, powder-based CoPolyester hot melt adhesives offer distinct benefits, especially in applications requiring a more controlled and uniform distribution of adhesive. The powder form allows for even coating over large surfaces, making it suitable for textile and packaging applications where a smooth and consistent adhesive layer is necessary. Powder adhesives can be applied using various techniques, including electrostatic spraying and fluidized bed coating, providing flexibility in application methods. This versatility makes powder-based adhesives an attractive choice for manufacturers looking to optimize their production processes. Both granulat and powder forms of CoPolyester hot melt adhesives are designed to meet the specific needs of different industries, offering tailored solutions that enhance product performance and manufacturing efficiency. The choice between granulat and powder forms often depends on the specific requirements of the application, such as the type of substrate, desired bond strength, and production environment. As the demand for high-performance adhesives continues to grow, manufacturers are increasingly focusing on developing innovative formulations and application techniques to meet the evolving needs of their customers. This includes advancements in adhesive technology that improve bonding strength, reduce application time, and enhance the overall durability of the adhesive bond. The Global CoPolyester Hot Melt Adhesives Market is characterized by ongoing research and development efforts aimed at expanding the range of applications and improving the performance of these adhesives. This includes exploring new raw materials and formulations that offer enhanced properties, such as increased heat resistance, improved flexibility, and greater environmental sustainability. As industries continue to seek more efficient and sustainable bonding solutions, the demand for granulat and powder-based CoPolyester hot melt adhesives is expected to rise, driving innovation and growth in the market. The ability to provide customized adhesive solutions that meet the specific needs of different industries is a key factor contributing to the success and expansion of the Global CoPolyester Hot Melt Adhesives Market.

Packing, Textile, Automotive, Others in the Global CoPolyester Hot Melt Adhesives Market:

The usage of Global CoPolyester Hot Melt Adhesives Market spans across various industries, each benefiting from the unique properties and advantages of these adhesives. In the packaging industry, CoPolyester hot melt adhesives are widely used for sealing cartons, boxes, and other packaging materials. Their quick-setting nature and strong bonding capabilities make them ideal for high-speed packaging lines, ensuring that products are securely sealed and protected during transportation and storage. Additionally, these adhesives offer excellent resistance to temperature fluctuations and moisture, which is crucial for maintaining the integrity of packaged goods. In the textile industry, CoPolyester hot melt adhesives are used for bonding fabrics and other materials, providing a durable and flexible bond that withstands repeated washing and wear. They are commonly used in the production of garments, footwear, and home textiles, where a strong yet flexible adhesive is required. The automotive industry also benefits from the use of CoPolyester hot melt adhesives, particularly in applications where lightweight and durable bonding solutions are needed. These adhesives are used for bonding interior components, such as upholstery and trim, as well as for attaching exterior parts like emblems and moldings. Their ability to bond with a variety of substrates, including plastics and metals, makes them a versatile choice for automotive manufacturers looking to improve vehicle performance and reduce weight. Beyond these industries, CoPolyester hot melt adhesives find applications in a range of other sectors, including electronics, woodworking, and construction. In electronics, they are used for encapsulating components and providing insulation, while in woodworking, they offer strong and reliable bonding for furniture and cabinetry. The construction industry utilizes these adhesives for bonding insulation materials and other building components, where a strong and durable adhesive is essential. The versatility and performance of CoPolyester hot melt adhesives make them a valuable tool for manufacturers across different industries, providing reliable and efficient bonding solutions that enhance product quality and performance.

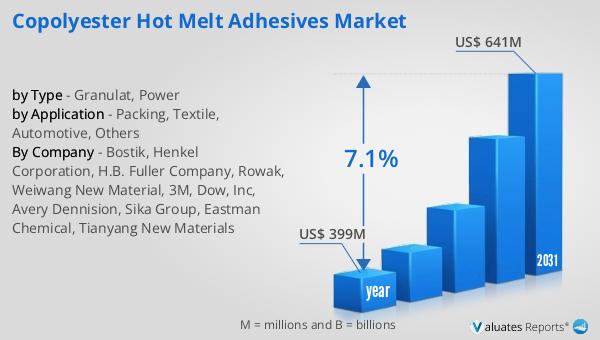

Global CoPolyester Hot Melt Adhesives Market Outlook:

The global market for CoPolyester Hot Melt Adhesives was valued at approximately $399 million in 2024, and it is anticipated to grow significantly, reaching an estimated $641 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.1% over the forecast period. This upward trajectory is indicative of the increasing demand for CoPolyester hot melt adhesives across various industries, driven by their superior bonding properties and environmental benefits. As industries continue to prioritize sustainable and efficient manufacturing processes, the demand for high-performance adhesives like CoPolyester hot melts is expected to rise. The market's growth is also fueled by advancements in adhesive technology, which are expanding the range of applications and improving the performance of these adhesives. Manufacturers are investing in research and development to create innovative adhesive solutions that meet the evolving needs of their customers, further driving market expansion. The projected growth of the Global CoPolyester Hot Melt Adhesives Market underscores the importance of these adhesives in modern manufacturing and highlights their potential to contribute to more sustainable and efficient production processes. As the market continues to evolve, it is expected to offer new opportunities for manufacturers and consumers alike, fostering innovation and growth in the adhesives industry.

| Report Metric | Details |

| Report Name | CoPolyester Hot Melt Adhesives Market |

| Accounted market size in year | US$ 399 million |

| Forecasted market size in 2031 | US$ 641 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Bostik, Henkel Corporation, H.B. Fuller Company, Rowak, Weiwang New Material, 3M, Dow, Inc, Avery Dennision, Sika Group, Eastman Chemical, Tianyang New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |