What is Global Conductive 3D Printer Filament Market?

The Global Conductive 3D Printer Filament Market is a rapidly evolving segment within the broader 3D printing industry, characterized by its unique ability to conduct electricity. This market focuses on the development and distribution of specialized filaments that are infused with conductive materials, such as carbon or metal particles, enabling them to transmit electrical currents. These filaments are essential for creating functional electronic components and devices using 3D printing technology. The demand for conductive 3D printer filaments is driven by the growing need for rapid prototyping and the production of customized electronic components across various industries, including automotive, aerospace, consumer electronics, and healthcare. As industries continue to embrace 3D printing for its efficiency and cost-effectiveness, the conductive filament market is expected to expand, offering innovative solutions for complex electronic designs. The versatility of these filaments allows for the creation of intricate circuit designs, sensors, and other electronic components, making them a valuable asset in the advancement of technology. As the market evolves, manufacturers are focusing on enhancing the conductivity, strength, and flexibility of these filaments to meet the diverse needs of different applications, ensuring their continued relevance and growth in the global market.

1.75MM, 2.85MM in the Global Conductive 3D Printer Filament Market:

In the Global Conductive 3D Printer Filament Market, filament diameters such as 1.75MM and 2.85MM play a crucial role in determining the quality and precision of 3D printed objects. The 1.75MM filament is widely popular due to its compatibility with a majority of 3D printers and its ability to produce fine details in printed objects. This diameter is particularly favored for intricate designs and applications where precision is paramount. The smaller diameter allows for a smoother flow of material through the printer nozzle, resulting in high-resolution prints with minimal layer lines. This makes the 1.75MM filament ideal for applications in electronics where detailed circuit paths and components are required. On the other hand, the 2.85MM filament, while less common, is preferred for applications that demand higher strength and durability. The larger diameter provides a more robust filament, which is beneficial for printing larger objects or components that require additional structural integrity. This makes the 2.85MM filament suitable for industrial applications where the printed parts need to withstand mechanical stress or environmental factors. Additionally, the 2.85MM filament can be advantageous in reducing print times for larger objects, as the increased material flow can fill larger volumes more quickly. Both filament diameters have their unique advantages and are chosen based on the specific requirements of the application. Manufacturers in the conductive 3D printer filament market are continually innovating to improve the properties of these filaments, such as enhancing their conductivity, flexibility, and strength. This ensures that both 1.75MM and 2.85MM filaments can meet the evolving demands of various industries, from consumer electronics to automotive and aerospace. As the market grows, the availability of high-quality conductive filaments in different diameters will provide designers and engineers with the tools they need to push the boundaries of what is possible with 3D printing technology. The choice between 1.75MM and 2.85MM filaments ultimately depends on the specific needs of the project, including the desired level of detail, strength, and speed of production. By understanding the unique characteristics of each filament diameter, users can make informed decisions that optimize the performance and functionality of their 3D printed electronic components.

Circuit Board, Sensor, Other in the Global Conductive 3D Printer Filament Market:

The Global Conductive 3D Printer Filament Market finds its applications in various areas, including circuit boards, sensors, and other electronic components. In the realm of circuit boards, conductive filaments offer a revolutionary approach to prototyping and manufacturing. Traditional circuit board production involves complex processes and significant lead times, but with conductive 3D printing, designers can quickly create and test circuit layouts. This rapid prototyping capability allows for faster iterations and innovations, reducing the time and cost associated with bringing new electronic products to market. Conductive filaments enable the printing of intricate circuit paths directly onto substrates, facilitating the creation of custom circuit boards tailored to specific applications. In the field of sensors, conductive 3D printer filaments provide a versatile solution for developing a wide range of sensor types, from pressure and temperature sensors to biosensors. The ability to print sensors with conductive filaments allows for the integration of sensing capabilities into complex geometries and structures that would be challenging to achieve with traditional manufacturing methods. This opens up new possibilities for creating smart devices and systems that can monitor and respond to environmental changes in real-time. The flexibility and adaptability of conductive filaments make them ideal for producing sensors that can be embedded into wearable technology, medical devices, and industrial equipment. Beyond circuit boards and sensors, conductive 3D printer filaments are also used in various other applications, such as creating electromagnetic shielding, antennas, and connectors. The ability to print conductive components directly into devices simplifies the manufacturing process and reduces the need for additional assembly steps. This not only streamlines production but also enhances the performance and reliability of the final product. As industries continue to explore the potential of 3D printing, the use of conductive filaments is expected to expand into new areas, driving innovation and enabling the development of next-generation electronic devices. The versatility of conductive 3D printer filaments makes them a valuable tool for engineers and designers looking to push the boundaries of what is possible with additive manufacturing. By leveraging the unique properties of these filaments, companies can create highly customized and functional electronic components that meet the specific needs of their applications.

Global Conductive 3D Printer Filament Market Outlook:

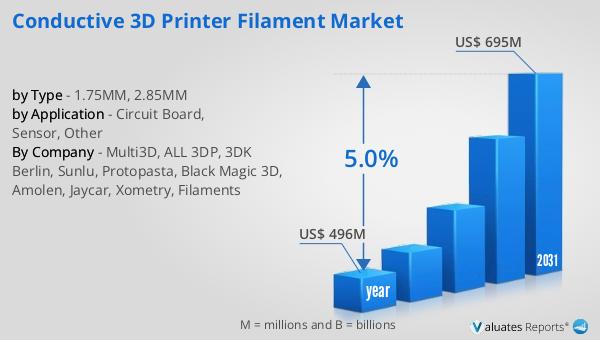

The outlook for the Global Conductive 3D Printer Filament Market indicates a promising future, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 496 million, reflecting the increasing demand for innovative 3D printing solutions in various industries. As technology continues to advance and the benefits of conductive 3D printing become more widely recognized, the market is projected to expand further. By 2031, it is expected to reach a revised size of US$ 695 million, driven by a compound annual growth rate (CAGR) of 5.0% during the forecast period. This growth can be attributed to the rising adoption of 3D printing technology for the production of electronic components, as well as the ongoing development of new and improved conductive filaments. The market's expansion is also supported by the increasing need for rapid prototyping and customization in industries such as automotive, aerospace, and consumer electronics. As more companies invest in 3D printing capabilities, the demand for high-quality conductive filaments is likely to rise, further fueling market growth. The continuous innovation in filament materials and the development of advanced 3D printing technologies are expected to enhance the performance and functionality of conductive filaments, making them an integral part of the future of manufacturing.

| Report Metric | Details |

| Report Name | Conductive 3D Printer Filament Market |

| Accounted market size in year | US$ 496 million |

| Forecasted market size in 2031 | US$ 695 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Multi3D, ALL 3DP, 3DK Berlin, Sunlu, Protopasta, Black Magic 3D, Amolen, Jaycar, Xometry, Filaments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |