What is Global Coatings for Automotive Lighting Market?

The Global Coatings for Automotive Lighting Market is a specialized segment within the broader automotive industry that focuses on the development and application of coatings specifically designed for automotive lighting components. These coatings are crucial for enhancing the performance, durability, and aesthetic appeal of lighting systems in vehicles. Automotive lighting includes headlights, taillights, fog lights, and interior lighting, all of which require coatings to protect against environmental factors such as UV radiation, moisture, and temperature fluctuations. The coatings also play a significant role in improving the light transmission and clarity of the lighting components, ensuring optimal visibility and safety for drivers. As the automotive industry continues to evolve with advancements in technology and design, the demand for high-quality coatings that can meet the stringent requirements of modern vehicles is on the rise. This market is driven by factors such as the increasing production of vehicles, the growing emphasis on vehicle safety and aesthetics, and the need for energy-efficient lighting solutions. Manufacturers in this market are continually innovating to develop coatings that offer superior performance, sustainability, and cost-effectiveness, catering to the diverse needs of automotive manufacturers and consumers worldwide.

Water Borne Coatings, Oil Borne Coatings in the Global Coatings for Automotive Lighting Market:

Water Borne Coatings and Oil Borne Coatings are two primary types of coatings used in the Global Coatings for Automotive Lighting Market, each with distinct characteristics and applications. Water Borne Coatings are formulated using water as the primary solvent, making them an environmentally friendly option due to their low volatile organic compound (VOC) emissions. These coatings are gaining popularity in the automotive industry as they align with the increasing regulatory pressures to reduce environmental impact. Water Borne Coatings offer excellent adhesion, corrosion resistance, and durability, making them suitable for various automotive lighting applications. They are particularly effective in providing a clear, protective layer that enhances the longevity and performance of lighting components. Additionally, advancements in waterborne technology have led to improved drying times and application processes, making them a viable alternative to traditional solvent-based coatings. On the other hand, Oil Borne Coatings, also known as solvent-based coatings, use organic solvents as the primary medium. These coatings have been traditionally favored for their superior finish, durability, and resistance to harsh environmental conditions. Oil Borne Coatings are known for their ability to provide a high-gloss finish and excellent protection against UV radiation, moisture, and temperature extremes, which are critical for maintaining the performance and appearance of automotive lighting systems. Despite their advantages, the use of Oil Borne Coatings is being scrutinized due to their higher VOC emissions, which contribute to air pollution and pose health risks. As a result, there is a growing shift towards more sustainable alternatives, such as Water Borne Coatings, in the automotive industry. The choice between Water Borne and Oil Borne Coatings in the automotive lighting market depends on various factors, including regulatory requirements, environmental considerations, performance needs, and cost implications. Manufacturers are increasingly investing in research and development to enhance the properties of Water Borne Coatings, aiming to match or exceed the performance of traditional Oil Borne Coatings. This includes improving their resistance to chemicals, abrasion, and weathering, as well as optimizing their application processes to ensure efficiency and cost-effectiveness. Furthermore, the development of hybrid coatings that combine the benefits of both waterborne and solvent-based technologies is an emerging trend in the market, offering a balanced solution that meets the diverse needs of automotive manufacturers. In conclusion, both Water Borne and Oil Borne Coatings play a vital role in the Global Coatings for Automotive Lighting Market, each offering unique benefits and challenges. As the industry continues to evolve, the focus is increasingly on developing sustainable, high-performance coatings that meet the stringent demands of modern automotive lighting systems. This shift is driven by the need to balance environmental responsibility with the performance and aesthetic requirements of automotive manufacturers and consumers. As a result, the market is witnessing a dynamic transformation, with innovative solutions emerging to address the complex challenges of automotive lighting coatings.

Passenger Vehicle, Commercial Vehicle in the Global Coatings for Automotive Lighting Market:

The usage of Global Coatings for Automotive Lighting Market in passenger vehicles and commercial vehicles is integral to ensuring the safety, efficiency, and aesthetic appeal of these vehicles. In passenger vehicles, automotive lighting plays a crucial role in enhancing visibility and safety for drivers and passengers. Coatings for automotive lighting in passenger vehicles are designed to provide a clear, protective layer that enhances the performance and longevity of lighting components such as headlights, taillights, and interior lights. These coatings help in maintaining the clarity and brightness of the lights, ensuring optimal visibility in various driving conditions. Additionally, the aesthetic appeal of passenger vehicles is significantly influenced by the quality and appearance of their lighting systems. Coatings that offer a high-gloss finish and resistance to environmental factors such as UV radiation and moisture are essential in maintaining the visual appeal of passenger vehicles. In commercial vehicles, the requirements for automotive lighting coatings are slightly different due to the nature of their usage. Commercial vehicles, such as trucks, buses, and delivery vans, often operate in more demanding environments and are subject to harsher conditions compared to passenger vehicles. As a result, the coatings used for automotive lighting in commercial vehicles need to offer superior durability, resistance to abrasion, and protection against harsh weather conditions. These coatings ensure that the lighting systems in commercial vehicles remain functional and effective, providing the necessary visibility and safety for drivers and other road users. Furthermore, the efficiency and reliability of lighting systems in commercial vehicles are critical for minimizing downtime and maintenance costs, making high-performance coatings a valuable investment for fleet operators. The choice of coatings for automotive lighting in both passenger and commercial vehicles is influenced by factors such as regulatory requirements, environmental considerations, and cost-effectiveness. Manufacturers are increasingly adopting sustainable coating solutions that reduce environmental impact while meeting the performance and aesthetic demands of modern vehicles. This includes the use of Water Borne Coatings, which offer low VOC emissions and excellent performance characteristics, making them a preferred choice for environmentally conscious manufacturers. Additionally, advancements in coating technologies are enabling the development of coatings that offer enhanced resistance to chemicals, abrasion, and weathering, ensuring the longevity and reliability of automotive lighting systems in both passenger and commercial vehicles. In summary, the Global Coatings for Automotive Lighting Market plays a vital role in the automotive industry by providing solutions that enhance the safety, efficiency, and aesthetic appeal of both passenger and commercial vehicles. The coatings used in automotive lighting systems are essential for maintaining the performance and longevity of these components, ensuring optimal visibility and safety for drivers and passengers. As the industry continues to evolve, the focus is increasingly on developing sustainable, high-performance coatings that meet the diverse needs of automotive manufacturers and consumers. This dynamic market is witnessing continuous innovation, with new solutions emerging to address the complex challenges of automotive lighting coatings in both passenger and commercial vehicles.

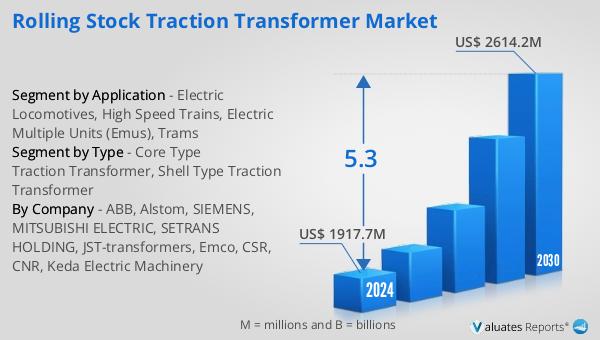

Global Coatings for Automotive Lighting Market Outlook:

The global market for Coatings for Automotive Lighting was valued at approximately $1,302 million in 2024, and it is anticipated to grow to a revised size of around $1,695 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.9% over the forecast period. The steady increase in market size reflects the rising demand for advanced coatings that enhance the performance and durability of automotive lighting systems. As the automotive industry continues to innovate and evolve, the need for high-quality coatings that can withstand environmental challenges and improve the aesthetic appeal of vehicles is becoming increasingly important. This market growth is driven by factors such as the increasing production of vehicles, the growing emphasis on vehicle safety and aesthetics, and the need for energy-efficient lighting solutions. Manufacturers in this market are continually innovating to develop coatings that offer superior performance, sustainability, and cost-effectiveness, catering to the diverse needs of automotive manufacturers and consumers worldwide. The projected growth in the market size underscores the importance of coatings in the automotive industry and highlights the ongoing efforts to develop innovative solutions that meet the evolving demands of modern vehicles.

| Report Metric | Details |

| Report Name | Coatings for Automotive Lighting Market |

| Accounted market size in year | US$ 1302 million |

| Forecasted market size in 2031 | US$ 1695 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BASF, Axalta, PPG Industries, Nippon Paint, AkzoNobel, Sherwin Williams, Kansai Paint, Xiangjiang Kansai Paint, Specialty Coating Systems (SCS) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |