What is Global Ceramic Injection Molding Materials Market?

The Global Ceramic Injection Molding (CIM) Materials Market is a specialized segment within the broader materials industry, focusing on the production and application of ceramic components through injection molding techniques. This market is driven by the unique properties of ceramics, such as high strength, wear resistance, and thermal stability, which make them ideal for various industrial applications. Ceramic injection molding is a process that combines the versatility of plastic injection molding with the superior material properties of ceramics. This technique allows for the mass production of complex ceramic parts with high precision and minimal waste. The market encompasses a range of materials, including oxide ceramics, non-oxide ceramics, and composite materials, each offering distinct advantages depending on the application. The demand for ceramic injection molding materials is growing across various sectors, including medical, automotive, and electronics, due to their ability to enhance product performance and durability. As industries continue to seek materials that offer both performance and cost-effectiveness, the Global Ceramic Injection Molding Materials Market is poised for steady growth, driven by technological advancements and increasing adoption across diverse applications.

Oxide Ceramics, Non-oxide Ceramics, Composite Materials in the Global Ceramic Injection Molding Materials Market:

Oxide ceramics, non-oxide ceramics, and composite materials are the primary categories within the Global Ceramic Injection Molding Materials Market, each offering unique properties and applications. Oxide ceramics, such as alumina and zirconia, are known for their excellent thermal and chemical stability, making them suitable for high-temperature applications and environments where chemical resistance is crucial. Alumina, for instance, is widely used in electrical insulators and wear-resistant components due to its hardness and insulating properties. Zirconia, on the other hand, is valued for its toughness and is often used in dental implants and cutting tools. Non-oxide ceramics, including silicon carbide and silicon nitride, offer exceptional mechanical strength and thermal conductivity. These materials are ideal for applications requiring high wear resistance and thermal shock resistance, such as in automotive engine components and industrial machinery. Silicon carbide is particularly noted for its hardness and is used in abrasive and cutting applications, while silicon nitride is favored in high-temperature applications due to its thermal stability and resistance to oxidation. Composite materials in the ceramic injection molding market combine the properties of different ceramics or ceramics with other materials to enhance performance characteristics. These composites can be tailored to meet specific application requirements, offering a balance of strength, toughness, and thermal properties. For example, ceramic matrix composites are used in aerospace and defense applications where lightweight and high-strength materials are essential. The versatility of composite materials allows for innovation and customization in product design, making them increasingly popular in industries seeking advanced material solutions. Overall, the diversity of materials within the Global Ceramic Injection Molding Materials Market enables manufacturers to select the most appropriate material for their specific needs, driving innovation and efficiency across various sectors.

Medical and Dental, Textile Industry, Automotive, Electrical, Household Appliances, Other in the Global Ceramic Injection Molding Materials Market:

The Global Ceramic Injection Molding Materials Market finds extensive usage across several industries, each benefiting from the unique properties of ceramic materials. In the medical and dental fields, ceramic injection molding materials are used to produce components such as dental implants, surgical instruments, and prosthetic devices. The biocompatibility, strength, and wear resistance of ceramics make them ideal for medical applications where precision and durability are paramount. In the textile industry, ceramics are used in components like thread guides and yarn carriers, where their wear resistance and low friction properties enhance the efficiency and longevity of textile machinery. The automotive industry utilizes ceramic injection molding materials in engine components, sensors, and exhaust systems, where their thermal stability and resistance to wear and corrosion improve vehicle performance and reliability. In the electrical sector, ceramics are used in insulators, capacitors, and other components that require excellent electrical insulation and thermal management. Household appliances also benefit from ceramic materials, with applications in heating elements, seals, and bearings, where their durability and thermal resistance contribute to product longevity and efficiency. Beyond these industries, ceramic injection molding materials are used in various other applications, including aerospace, defense, and consumer electronics, where their unique properties offer solutions to complex engineering challenges. The versatility and performance of ceramic materials continue to drive their adoption across diverse sectors, highlighting their importance in modern manufacturing and product development.

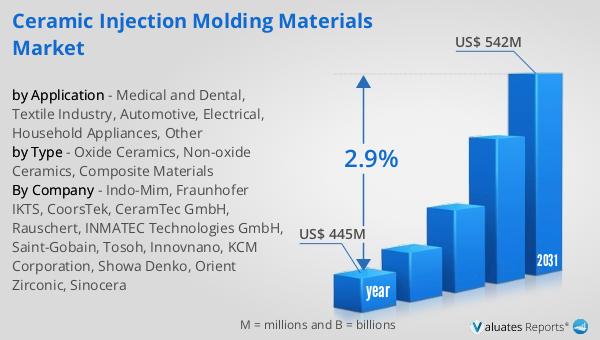

Global Ceramic Injection Molding Materials Market Outlook:

The global market for Ceramic Injection Molding Materials, initially valued at $445 million in 2024, is anticipated to expand to a revised valuation of $542 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 2.9% over the forecast period. This steady growth is indicative of the increasing demand for ceramic materials across various industries, driven by their superior properties and the technological advancements in injection molding techniques. The market's expansion is fueled by the rising need for high-performance materials that can withstand extreme conditions and offer enhanced durability and efficiency. As industries such as automotive, medical, and electronics continue to evolve, the demand for ceramic injection molding materials is expected to rise, supporting the market's growth. The projected increase in market size reflects the ongoing innovation and adoption of ceramic materials in new and existing applications, underscoring their critical role in modern manufacturing. This growth also highlights the importance of continued research and development in ceramic materials to meet the evolving needs of various industries and maintain the market's upward trajectory.

| Report Metric | Details |

| Report Name | Ceramic Injection Molding Materials Market |

| Accounted market size in year | US$ 445 million |

| Forecasted market size in 2031 | US$ 542 million |

| CAGR | 2.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Indo-Mim, Fraunhofer IKTS, CoorsTek, CeramTec GmbH, Rauschert, INMATEC Technologies GmbH, Saint-Gobain, Tosoh, Innovnano, KCM Corporation, Showa Denko, Orient Zirconic, Sinocera |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |