What is Global Brass Wire for Trolley Case Market?

The Global Brass Wire for Trolley Case Market is a niche segment within the broader market for materials used in luggage manufacturing. Brass wire is a key component in the production of trolley cases, which are a type of luggage equipped with wheels and a retractable handle for easy transportation. The use of brass wire in trolley cases is primarily due to its excellent properties, such as corrosion resistance, durability, and aesthetic appeal. These properties make brass wire an ideal material for reinforcing the structural integrity of trolley cases, ensuring they can withstand the rigors of travel. The market for brass wire in this application is influenced by factors such as the growth in global travel, increasing consumer demand for durable and stylish luggage, and advancements in manufacturing technologies. As travel becomes more accessible and frequent, the demand for high-quality trolley cases is expected to rise, thereby driving the market for brass wire used in their production. The market is characterized by a variety of brass wire types, each offering distinct properties that cater to different needs and preferences in trolley case manufacturing.

Brass Wire 230 (UNS C23000), Brass Wire 240 (UNS C24000), Brass Wire 260 (UNS C26000), Others in the Global Brass Wire for Trolley Case Market:

Brass Wire 230 (UNS C23000), Brass Wire 240 (UNS C24000), and Brass Wire 260 (UNS C26000) are specific types of brass wire used in the Global Brass Wire for Trolley Case Market, each offering unique characteristics that make them suitable for different applications. Brass Wire 230, also known as red brass, is composed of approximately 85% copper and 15% zinc. This composition gives it excellent corrosion resistance and a reddish hue, making it an attractive choice for decorative elements in trolley cases. Its high copper content also provides good electrical conductivity, which can be beneficial in cases where electronic components are integrated into the luggage. Brass Wire 240, on the other hand, contains a slightly higher zinc content, typically around 20%, which enhances its strength and hardness compared to Brass Wire 230. This makes it suitable for structural components of trolley cases that require additional durability, such as frames and handles. The increased zinc content also gives Brass Wire 240 a more yellowish appearance, which can be desirable for certain aesthetic designs. Brass Wire 260, commonly referred to as cartridge brass, contains about 30% zinc and 70% copper. This composition provides a good balance of strength, ductility, and corrosion resistance, making it a versatile choice for various components of trolley cases. Its ability to be easily formed and machined allows manufacturers to create intricate designs and shapes, enhancing the overall functionality and appeal of the luggage. Additionally, Brass Wire 260's bright gold-like appearance adds a touch of luxury to trolley cases, appealing to consumers seeking premium products. Beyond these specific types, the market also includes other brass wire variants that cater to specialized needs. These may include brass wires with additional alloying elements to enhance specific properties, such as increased tensile strength or improved resistance to specific environmental conditions. The choice of brass wire type in trolley case manufacturing depends on several factors, including the desired balance between aesthetics and functionality, cost considerations, and the specific requirements of the target consumer segment. Manufacturers often collaborate with material scientists and engineers to select the most appropriate brass wire for their products, ensuring that the final trolley cases meet the expectations of durability, style, and performance. As the market for trolley cases continues to evolve, driven by changing consumer preferences and technological advancements, the demand for high-quality brass wire is expected to remain strong. This ongoing demand underscores the importance of understanding the distinct properties and applications of different brass wire types in the Global Brass Wire for Trolley Case Market.

Men's Trolley Case, Women's Trolley Case in the Global Brass Wire for Trolley Case Market:

The usage of Global Brass Wire for Trolley Case Market in men's and women's trolley cases highlights the versatility and adaptability of this material in catering to diverse consumer needs. In men's trolley cases, brass wire is often used to enhance the structural integrity and durability of the luggage. Men typically prefer trolley cases that are robust and capable of withstanding frequent travel, whether for business or leisure. Brass wire, with its excellent strength and corrosion resistance, ensures that the frames and handles of men's trolley cases can endure the wear and tear of regular use. Additionally, the aesthetic appeal of brass wire, with its metallic sheen, adds a touch of sophistication to men's luggage, aligning with the preference for sleek and professional designs. In women's trolley cases, the use of brass wire extends beyond functionality to include decorative elements. Women often seek luggage that combines practicality with style, and brass wire offers the perfect solution. Its ability to be easily formed into intricate patterns and designs allows manufacturers to create trolley cases that are not only durable but also visually appealing. The warm tones of brass wire complement a wide range of colors and materials, enabling the creation of fashionable luggage that resonates with women's preferences. Furthermore, the lightweight nature of brass wire contributes to the overall ease of handling and maneuverability of women's trolley cases, a crucial factor for consumers who prioritize convenience during travel. The integration of brass wire in both men's and women's trolley cases also reflects the growing trend towards personalized and customizable luggage. Consumers today are increasingly looking for products that reflect their individual style and personality, and brass wire provides the flexibility needed to achieve this. Manufacturers can offer a variety of finishes, from polished to matte, and incorporate unique design elements that cater to the specific tastes of men and women. This customization potential enhances the appeal of trolley cases in the market, attracting a broader consumer base. Moreover, the use of brass wire in trolley cases aligns with the sustainability movement in the luggage industry. Brass is a recyclable material, and its durability ensures a longer lifespan for trolley cases, reducing the need for frequent replacements. This eco-friendly aspect is particularly appealing to environmentally conscious consumers, who are increasingly considering the environmental impact of their purchases. By incorporating brass wire into their products, manufacturers can position themselves as responsible and sustainable brands, further enhancing their market competitiveness. Overall, the usage of Global Brass Wire for Trolley Case Market in men's and women's trolley cases underscores the material's ability to meet the diverse demands of modern consumers. Its combination of strength, aesthetics, and sustainability makes brass wire an indispensable component in the production of high-quality luggage that caters to the evolving needs of both men and women.

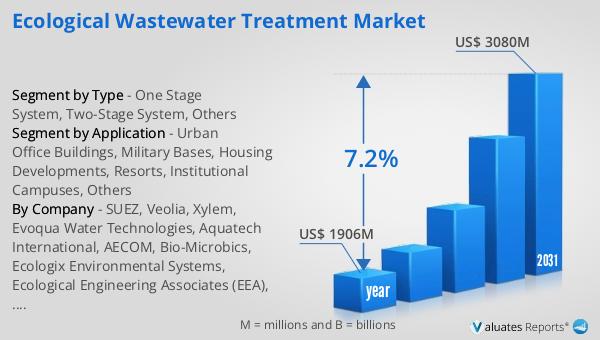

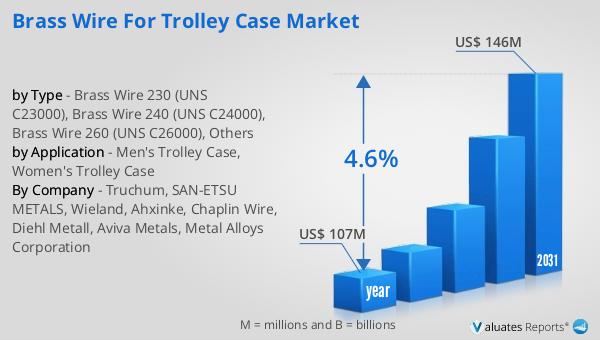

Global Brass Wire for Trolley Case Market Outlook:

The global market for Brass Wire for Trolley Case was valued at $107 million in 2024, and it is anticipated to grow to a revised size of $146 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.6% during the forecast period. This growth trajectory highlights the increasing demand for brass wire in the trolley case industry, driven by factors such as the rising popularity of travel and tourism, advancements in luggage design, and the growing consumer preference for durable and stylish luggage options. The market's expansion is also supported by the ongoing trend towards personalization and customization in the luggage industry, with consumers seeking products that reflect their individual style and preferences. As manufacturers continue to innovate and enhance the functionality and aesthetics of trolley cases, the demand for high-quality materials like brass wire is expected to remain strong. This positive market outlook underscores the importance of brass wire as a key component in the production of trolley cases, offering a combination of strength, durability, and aesthetic appeal that meets the evolving needs of modern travelers. The projected growth in the market also presents opportunities for manufacturers to expand their product offerings and capture a larger share of the global luggage market.

| Report Metric | Details |

| Report Name | Brass Wire for Trolley Case Market |

| Accounted market size in year | US$ 107 million |

| Forecasted market size in 2031 | US$ 146 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Truchum, SAN-ETSU METALS, Wieland, Ahxinke, Chaplin Wire, Diehl Metall, Aviva Metals, Metal Alloys Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |