What is Global Aluminum Plastic Film for Lithium Battery Market?

The Global Aluminum Plastic Film for Lithium Battery Market is a specialized segment within the broader lithium battery industry. This market focuses on the production and distribution of aluminum plastic films, which are crucial components in lithium batteries. These films serve as protective layers that encase the battery cells, providing insulation and safeguarding against external factors that could potentially damage the battery. The demand for aluminum plastic films is driven by the increasing adoption of lithium batteries in various applications, such as consumer electronics, electric vehicles, and energy storage systems. As the world shifts towards renewable energy and electric mobility, the need for efficient and reliable battery technologies becomes paramount. Aluminum plastic films play a vital role in enhancing the performance and safety of lithium batteries, making them indispensable in the quest for sustainable energy solutions. The market is characterized by continuous innovation and technological advancements, as manufacturers strive to develop films with improved properties, such as higher thermal stability and better mechanical strength. This dynamic landscape presents numerous opportunities for growth and development, as companies seek to capitalize on the rising demand for lithium batteries across the globe.

Thickness 88μm, Thickness 113μm, Thickness 152μm, Others in the Global Aluminum Plastic Film for Lithium Battery Market:

In the Global Aluminum Plastic Film for Lithium Battery Market, the thickness of the film is a critical factor that influences its performance and suitability for different applications. The thickness of the film is measured in micrometers (μm), and it determines the film's mechanical properties, such as strength, flexibility, and thermal resistance. Films with a thickness of 88μm are typically used in applications where lightweight and flexibility are prioritized. These films are often employed in consumer electronics, where the compact size and weight of the battery are crucial considerations. The 88μm films provide adequate protection and insulation while maintaining a slim profile, making them ideal for devices like smartphones, tablets, and laptops. On the other hand, films with a thickness of 113μm offer a balance between strength and flexibility. They are commonly used in power lithium batteries, which require a higher level of durability and thermal stability. These batteries are often found in electric vehicles and other high-performance applications, where the battery must withstand demanding conditions and deliver consistent power output. The 113μm films provide the necessary protection and support to ensure the battery's longevity and reliability. For applications that demand even greater strength and thermal resistance, films with a thickness of 152μm are utilized. These films are typically used in energy storage systems, where the batteries are subjected to prolonged cycles of charging and discharging. The 152μm films offer superior protection against mechanical stress and thermal fluctuations, ensuring the stability and efficiency of the energy storage system. In addition to these standard thicknesses, there are also other variations available in the market, catering to specific requirements and niche applications. Manufacturers continuously innovate and develop new film thicknesses to meet the evolving needs of the industry. This diversity in film thicknesses allows for greater flexibility and customization, enabling manufacturers to tailor their products to suit different applications and performance criteria. As the demand for lithium batteries continues to grow, the importance of selecting the appropriate film thickness becomes increasingly significant. The right choice of film thickness can enhance the battery's performance, safety, and lifespan, ultimately contributing to the overall success of the application.

3C Consumer Lithium Battery, Power Lithium Battery, Energy Storage Lithium Battery in the Global Aluminum Plastic Film for Lithium Battery Market:

The Global Aluminum Plastic Film for Lithium Battery Market finds its usage in various areas, including 3C Consumer Lithium Batteries, Power Lithium Batteries, and Energy Storage Lithium Batteries. In the realm of 3C Consumer Lithium Batteries, aluminum plastic films are essential components that ensure the safety and efficiency of batteries used in consumer electronics. These batteries power a wide range of devices, such as smartphones, tablets, laptops, and wearable gadgets. The aluminum plastic film acts as a protective barrier, preventing external factors like moisture and dust from compromising the battery's integrity. Additionally, it provides insulation and thermal management, which are crucial for maintaining the battery's performance and preventing overheating. As consumer electronics continue to evolve and demand for portable devices increases, the role of aluminum plastic films in enhancing battery safety and performance becomes even more critical. In Power Lithium Batteries, which are commonly used in electric vehicles and other high-performance applications, aluminum plastic films play a vital role in ensuring the battery's durability and reliability. These batteries are subjected to rigorous conditions, including high temperatures and mechanical stress, making the protective properties of the aluminum plastic film indispensable. The film provides a robust barrier that shields the battery cells from external impacts and thermal fluctuations, thereby extending the battery's lifespan and ensuring consistent power delivery. As the automotive industry shifts towards electric mobility, the demand for power lithium batteries and, consequently, aluminum plastic films is expected to rise significantly. Energy Storage Lithium Batteries, used in renewable energy systems and grid storage applications, also rely on aluminum plastic films for optimal performance. These batteries are designed to store and release energy over extended periods, making them crucial for balancing energy supply and demand. The aluminum plastic film provides the necessary protection against environmental factors and mechanical stress, ensuring the stability and efficiency of the energy storage system. As the world moves towards sustainable energy solutions, the importance of energy storage systems and the role of aluminum plastic films in enhancing their performance cannot be overstated. In summary, the Global Aluminum Plastic Film for Lithium Battery Market plays a pivotal role in various applications, contributing to the safety, efficiency, and longevity of lithium batteries across different sectors.

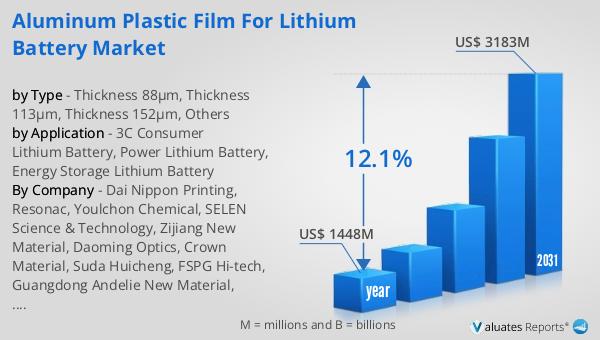

Global Aluminum Plastic Film for Lithium Battery Market Outlook:

The global market for Aluminum Plastic Film for Lithium Battery was valued at $1,448 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $3,183 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 12.1% over the forecast period. This impressive growth can be attributed to several factors, including the increasing demand for lithium batteries across various industries, such as consumer electronics, electric vehicles, and renewable energy systems. As the world continues to embrace sustainable energy solutions and electric mobility, the need for efficient and reliable battery technologies becomes more pronounced. Aluminum plastic films, being a critical component of lithium batteries, are poised to benefit from this trend. The market's expansion is also driven by continuous innovation and technological advancements, as manufacturers strive to develop films with enhanced properties, such as improved thermal stability and mechanical strength. This dynamic landscape presents numerous opportunities for growth and development, as companies seek to capitalize on the rising demand for lithium batteries globally. The projected growth of the Aluminum Plastic Film for Lithium Battery Market underscores the increasing importance of this component in the broader context of energy storage and electric mobility.

| Report Metric | Details |

| Report Name | Aluminum Plastic Film for Lithium Battery Market |

| Accounted market size in year | US$ 1448 million |

| Forecasted market size in 2031 | US$ 3183 million |

| CAGR | 12.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dai Nippon Printing, Resonac, Youlchon Chemical, SELEN Science & Technology, Zijiang New Material, Daoming Optics, Crown Material, Suda Huicheng, FSPG Hi-tech, Guangdong Andelie New Material, PUTAILAI, Jiangsu Leeden, HANGZHOU FIRST, WAZAM, Jangsu Huagu, SEMCORP, Tonytech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |