What is Global Aluminum Plastic Film for 3C Electronics Market?

The Global Aluminum Plastic Film for 3C Electronics Market is a specialized segment within the broader electronics materials industry. This market focuses on the production and application of aluminum plastic films, which are essential components in the manufacturing of 3C electronics—computers, communications, and consumer electronics. These films are primarily used as packaging materials for lithium-ion batteries, which power a wide range of electronic devices. The aluminum plastic film acts as a protective layer, ensuring the safety and efficiency of the batteries by providing excellent insulation and resistance to external factors such as moisture and temperature fluctuations. The demand for these films is driven by the increasing production of electronic devices, as well as the growing need for lightweight, durable, and efficient battery packaging solutions. As technology advances and the consumer electronics market expands, the role of aluminum plastic films becomes even more critical, making this market a key area of interest for manufacturers and investors alike. The market is characterized by continuous innovation, with companies striving to develop films that offer better performance, sustainability, and cost-effectiveness. This dynamic environment presents numerous opportunities for growth and development in the coming years.

88μm, 113μm, Others in the Global Aluminum Plastic Film for 3C Electronics Market:

In the Global Aluminum Plastic Film for 3C Electronics Market, the thickness of the film plays a crucial role in determining its application and performance. The most common thicknesses are 88μm and 113μm, with other variations available to meet specific requirements. The 88μm aluminum plastic film is typically used in applications where flexibility and lightweight properties are essential. This thickness is ideal for small to medium-sized batteries, often found in portable electronic devices such as smartphones and wearable gadgets. The thinner film allows for a more compact design, which is crucial in devices where space is at a premium. Additionally, the 88μm film provides adequate protection and insulation, ensuring the safety and longevity of the battery without adding unnecessary bulk. On the other hand, the 113μm aluminum plastic film is used in applications that require more robust protection and durability. This thicker film is suitable for larger batteries, such as those used in laptops and other high-capacity electronic devices. The increased thickness provides enhanced mechanical strength and better resistance to external factors, making it ideal for devices that are subject to more rigorous use and environmental conditions. The 113μm film also offers superior insulation properties, which are crucial for maintaining the performance and safety of larger batteries over extended periods. Apart from the standard 88μm and 113μm thicknesses, the market also offers other variations to cater to specific needs and applications. These custom thicknesses are developed based on the unique requirements of different electronic devices and their respective battery designs. Manufacturers often work closely with electronics companies to develop films that meet the precise specifications needed for optimal performance. This collaboration ensures that the aluminum plastic films not only provide the necessary protection and insulation but also contribute to the overall efficiency and sustainability of the electronic devices. The choice of film thickness is influenced by several factors, including the type of device, the size and capacity of the battery, and the specific performance requirements. For instance, in high-performance devices that require rapid charging and discharging cycles, a thicker film may be preferred to ensure stability and safety. Conversely, in ultra-portable devices where weight and size are critical, a thinner film may be more suitable. The versatility of aluminum plastic films in terms of thickness allows manufacturers to tailor their products to meet the diverse needs of the 3C electronics market. In conclusion, the thickness of aluminum plastic films is a key consideration in the Global Aluminum Plastic Film for 3C Electronics Market. The availability of different thicknesses, such as 88μm, 113μm, and others, provides manufacturers with the flexibility to address the specific needs of various electronic devices. This adaptability is essential in a market characterized by rapid technological advancements and evolving consumer demands. As the market continues to grow, the development of innovative film solutions that offer improved performance, sustainability, and cost-effectiveness will remain a priority for manufacturers and stakeholders.

Smartphones, Laptops, Wearable Devices, Others in the Global Aluminum Plastic Film for 3C Electronics Market:

The Global Aluminum Plastic Film for 3C Electronics Market plays a significant role in the production and functionality of various electronic devices, including smartphones, laptops, wearable devices, and others. In smartphones, aluminum plastic films are primarily used in the packaging of lithium-ion batteries. These films provide essential protection and insulation, ensuring the safety and efficiency of the batteries. The lightweight and flexible nature of the films allows for the compact design of smartphones, which is crucial in meeting consumer demands for sleek and portable devices. Additionally, the films contribute to the overall durability and longevity of the batteries, enhancing the performance and reliability of smartphones. In laptops, aluminum plastic films are used in the packaging of larger lithium-ion batteries that require more robust protection. The films provide excellent insulation and resistance to external factors such as temperature fluctuations and moisture, which are critical in maintaining the performance and safety of laptop batteries. The use of aluminum plastic films in laptops also contributes to the overall weight reduction of the devices, making them more portable and user-friendly. As laptops continue to evolve with more advanced features and capabilities, the demand for high-quality aluminum plastic films is expected to increase. Wearable devices, such as smartwatches and fitness trackers, also rely on aluminum plastic films for their battery packaging. The compact and lightweight nature of these devices necessitates the use of thin and flexible films that can accommodate the small battery sizes without compromising on protection and insulation. The films ensure the safety and efficiency of the batteries, allowing wearable devices to deliver consistent performance and reliability. As the market for wearable technology continues to grow, the role of aluminum plastic films in enhancing the functionality and durability of these devices becomes increasingly important. Beyond smartphones, laptops, and wearable devices, aluminum plastic films are used in a variety of other electronic devices. These include tablets, digital cameras, and portable gaming consoles, among others. In each of these applications, the films provide essential protection and insulation for the batteries, ensuring their safety and efficiency. The versatility of aluminum plastic films in terms of thickness and performance allows manufacturers to tailor their products to meet the specific needs of different devices, contributing to the overall advancement and innovation in the 3C electronics market. In summary, the Global Aluminum Plastic Film for 3C Electronics Market is integral to the production and functionality of a wide range of electronic devices. The films provide essential protection and insulation for lithium-ion batteries, ensuring their safety, efficiency, and longevity. As technology continues to advance and consumer demands evolve, the role of aluminum plastic films in enhancing the performance and reliability of electronic devices will remain crucial. Manufacturers and stakeholders in the market are likely to focus on developing innovative film solutions that offer improved performance, sustainability, and cost-effectiveness to meet the growing needs of the 3C electronics industry.

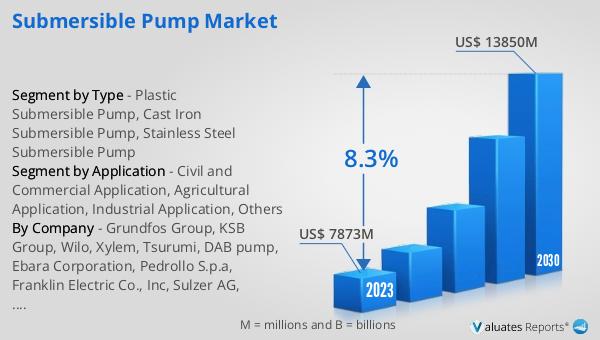

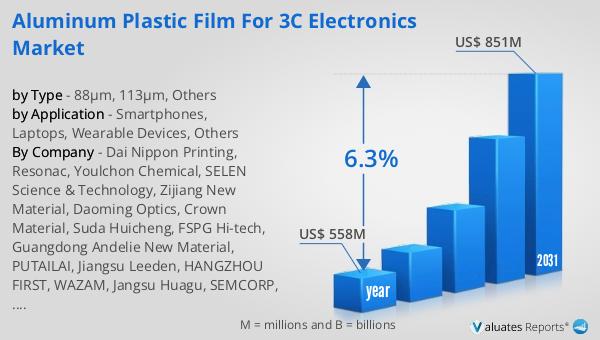

Global Aluminum Plastic Film for 3C Electronics Market Outlook:

In 2024, the global market for Aluminum Plastic Film for 3C Electronics was valued at approximately $558 million. This market is anticipated to grow significantly, reaching an estimated size of $851 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. The increasing demand for electronic devices, coupled with the need for efficient and reliable battery packaging solutions, is driving this market expansion. As technology continues to evolve and consumer preferences shift towards more advanced and portable devices, the demand for high-quality aluminum plastic films is expected to rise. These films play a crucial role in ensuring the safety, efficiency, and longevity of lithium-ion batteries, which are essential components in a wide range of electronic devices. The market's growth is also supported by continuous innovation and development in film technology, with manufacturers striving to create products that offer better performance, sustainability, and cost-effectiveness. As a result, the Global Aluminum Plastic Film for 3C Electronics Market presents numerous opportunities for growth and development, making it an attractive area for investment and exploration. The dynamic nature of this market, characterized by rapid technological advancements and evolving consumer demands, underscores the importance of staying ahead of trends and innovations to capitalize on emerging opportunities.

| Report Metric | Details |

| Report Name | Aluminum Plastic Film for 3C Electronics Market |

| Accounted market size in year | US$ 558 million |

| Forecasted market size in 2031 | US$ 851 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dai Nippon Printing, Resonac, Youlchon Chemical, SELEN Science & Technology, Zijiang New Material, Daoming Optics, Crown Material, Suda Huicheng, FSPG Hi-tech, Guangdong Andelie New Material, PUTAILAI, Jiangsu Leeden, HANGZHOU FIRST, WAZAM, Jangsu Huagu, SEMCORP, Tonytech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |