What is Global Aluminum Foam for Automotive Market?

The Global Aluminum Foam for Automotive Market is a niche yet rapidly evolving segment within the automotive industry. Aluminum foam is a lightweight material characterized by its unique cellular structure, which provides a combination of strength and low density. This makes it an ideal choice for automotive applications where weight reduction is crucial for improving fuel efficiency and reducing emissions. The market for aluminum foam in the automotive sector is driven by the increasing demand for lightweight materials that can enhance vehicle performance while ensuring safety and durability. Aluminum foam is used in various automotive components, including crash barriers, heat exchangers, and sound absorbers, due to its excellent energy absorption, thermal conductivity, and acoustic properties. As automakers strive to meet stringent environmental regulations and consumer demand for more efficient vehicles, the adoption of aluminum foam is expected to grow. This material not only contributes to the overall reduction of vehicle weight but also enhances safety features, making it a valuable component in modern automotive design. The global market for aluminum foam in the automotive industry is poised for significant growth as manufacturers continue to explore innovative applications and technologies to meet the evolving needs of the market.

Open-cell Aluminum Foam, Closed-cell Aluminum Foam in the Global Aluminum Foam for Automotive Market:

Open-cell and closed-cell aluminum foams are two primary types of aluminum foam used in the automotive industry, each offering distinct properties and applications. Open-cell aluminum foam is characterized by its interconnected pores, which allow fluids and gases to pass through. This type of foam is particularly useful in applications where fluid flow and filtration are required, such as in heat exchangers and sound absorbers. The open-cell structure provides excellent thermal conductivity, making it an ideal choice for dissipating heat in automotive components. Additionally, the porous nature of open-cell foam allows it to absorb sound waves, reducing noise and vibration within the vehicle cabin. This makes it a valuable material for enhancing passenger comfort and improving the overall driving experience. On the other hand, closed-cell aluminum foam features isolated pores, which provide superior strength and energy absorption capabilities. This makes it an excellent choice for crash barriers and other safety-related applications in the automotive industry. The closed-cell structure allows the foam to absorb and dissipate impact energy effectively, reducing the risk of injury to passengers during collisions. Furthermore, closed-cell aluminum foam is resistant to moisture and corrosion, ensuring long-term durability and reliability in harsh automotive environments. Both open-cell and closed-cell aluminum foams offer unique advantages that make them suitable for different automotive applications. As the demand for lightweight and high-performance materials continues to grow, the use of aluminum foam in the automotive industry is expected to expand, driven by the need for improved fuel efficiency, safety, and comfort. Manufacturers are increasingly exploring innovative ways to incorporate aluminum foam into vehicle design, leveraging its unique properties to enhance performance and meet the evolving demands of the market. The versatility of aluminum foam, combined with its lightweight and durable nature, makes it a valuable material for the automotive industry, offering a range of benefits that contribute to the development of more efficient and sustainable vehicles.

Crash Barrier, Heat Exchanger, Sound Absorber, Others in the Global Aluminum Foam for Automotive Market:

The usage of Global Aluminum Foam for Automotive Market in areas such as crash barriers, heat exchangers, sound absorbers, and others highlights the material's versatility and effectiveness in enhancing vehicle performance and safety. In crash barriers, aluminum foam is utilized for its exceptional energy absorption properties. During a collision, the foam compresses and absorbs the impact energy, reducing the force transmitted to the vehicle's occupants and minimizing the risk of injury. This makes aluminum foam an essential component in automotive safety systems, contributing to the development of safer vehicles. In heat exchangers, aluminum foam's high thermal conductivity and lightweight nature make it an ideal material for efficient heat dissipation. The open-cell structure of the foam allows for effective fluid flow, enhancing the heat exchange process and improving the overall efficiency of the vehicle's cooling system. This is particularly important in modern vehicles, where efficient thermal management is crucial for maintaining optimal performance and preventing overheating. As a sound absorber, aluminum foam's porous structure effectively reduces noise and vibration within the vehicle cabin. This enhances passenger comfort by minimizing road noise and improving the overall acoustic environment. The use of aluminum foam in sound absorption applications is particularly beneficial in electric and hybrid vehicles, where the absence of engine noise makes other sources of noise more noticeable. Additionally, aluminum foam is used in various other automotive applications, such as structural components and reinforcement panels, where its lightweight and durable nature contribute to overall vehicle weight reduction and improved fuel efficiency. The material's resistance to corrosion and environmental factors ensures long-term reliability and performance, making it a valuable asset in the development of modern vehicles. As the automotive industry continues to prioritize lightweight materials and advanced technologies, the use of aluminum foam is expected to grow, driven by the need for improved safety, efficiency, and sustainability.

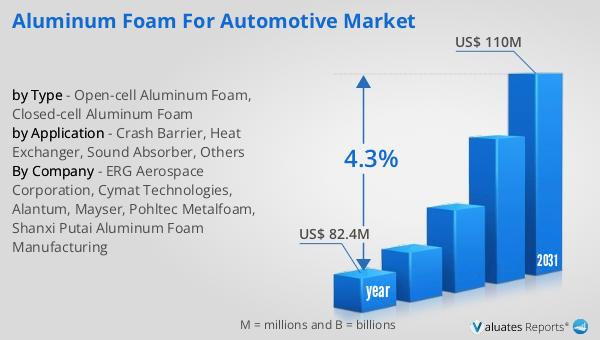

Global Aluminum Foam for Automotive Market Outlook:

The global market for aluminum foam in the automotive sector is experiencing a notable upward trajectory. In 2024, the market was valued at approximately $82.4 million. Projections indicate that by 2031, this figure is expected to reach around $110 million. This growth represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. This steady increase underscores the rising demand for lightweight and efficient materials in the automotive industry. Aluminum foam's unique properties, such as its lightweight nature, energy absorption capabilities, and thermal conductivity, make it an attractive choice for automakers seeking to enhance vehicle performance and safety. The material's ability to contribute to weight reduction and improved fuel efficiency aligns with the industry's focus on sustainability and environmental responsibility. As automakers continue to innovate and explore new applications for aluminum foam, the market is poised for continued expansion. The projected growth reflects the increasing recognition of aluminum foam's value in modern automotive design and its potential to address the evolving needs of the industry. With its combination of strength, durability, and versatility, aluminum foam is set to play a significant role in shaping the future of automotive manufacturing.

| Report Metric | Details |

| Report Name | Aluminum Foam for Automotive Market |

| Accounted market size in year | US$ 82.4 million |

| Forecasted market size in 2031 | US$ 110 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ERG Aerospace Corporation, Cymat Technologies, Alantum, Mayser, Pohltec Metalfoam, Shanxi Putai Aluminum Foam Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |