What is Global Vibration Friction Machine Market?

The Global Vibration Friction Machine Market refers to the industry that manufactures and sells machines designed to join materials through vibration and friction. These machines are widely used in various sectors such as automotive, electronics, and home appliances. The process involves generating heat through friction, which melts the materials at the interface, allowing them to fuse together when cooled. This method is highly efficient and provides strong, durable bonds without the need for additional adhesives or fasteners. The market for these machines is growing due to the increasing demand for lightweight and high-strength materials in various industries. Additionally, advancements in technology have led to the development of more sophisticated and efficient machines, further driving market growth. The global market is characterized by a mix of established players and new entrants, all competing to offer innovative solutions to meet the evolving needs of their customers.

Free or Natural Vibration, Forced Vibration, Damped Vibration in the Global Vibration Friction Machine Market:

In the context of the Global Vibration Friction Machine Market, vibrations can be categorized into three main types: Free or Natural Vibration, Forced Vibration, and Damped Vibration. Free or Natural Vibration occurs when a system oscillates due to an initial disturbance and continues to do so without any external force acting on it. This type of vibration is inherent to the system's properties, such as its mass and stiffness. For example, when a tuning fork is struck, it vibrates at its natural frequency until the energy dissipates. In the case of vibration friction machines, understanding natural vibration is crucial for designing systems that can handle the stresses and strains during the welding process. Forced Vibration, on the other hand, occurs when an external force drives the system to oscillate. This is common in many industrial applications where machines are subjected to periodic forces, such as motors or other mechanical devices. In vibration friction machines, forced vibration is often used to achieve the desired frictional heat for welding. The external force, usually in the form of mechanical oscillations, ensures that the materials being joined reach the necessary temperature for bonding. Damped Vibration involves the presence of a damping mechanism that reduces the amplitude of oscillations over time. This is essential in many practical applications to prevent excessive vibrations that could lead to mechanical failure or reduced efficiency. In vibration friction machines, damping mechanisms are often incorporated to control the vibration levels, ensuring that the welding process is stable and consistent. By understanding and controlling these different types of vibrations, manufacturers can optimize the performance and reliability of vibration friction machines, making them more effective for various industrial applications.

Automobile, Home Appliances, Others in the Global Vibration Friction Machine Market:

The Global Vibration Friction Machine Market finds extensive usage in several key areas, including the automobile industry, home appliances, and other sectors. In the automobile industry, these machines are used for welding various components such as fuel tanks, air intake manifolds, and instrument panels. The ability to create strong, durable bonds without adding extra weight is particularly valuable in automotive manufacturing, where reducing vehicle weight is crucial for improving fuel efficiency and performance. Additionally, vibration friction welding is used to join dissimilar materials, which is increasingly important as manufacturers look to combine different materials to optimize vehicle performance. In the realm of home appliances, vibration friction machines are employed to assemble parts of products like washing machines, refrigerators, and dishwashers. The precision and strength of the bonds created by these machines ensure the durability and reliability of household appliances, which are subjected to frequent use and various stresses. The ability to join plastic components without the need for adhesives or fasteners also simplifies the manufacturing process and reduces production costs. Beyond automobiles and home appliances, vibration friction machines are used in other industries such as electronics, medical devices, and aerospace. In electronics, these machines are used to assemble components like battery packs and connectors, where reliable and precise bonding is essential. In the medical field, vibration friction welding is used to manufacture devices such as surgical instruments and implants, where the integrity of the bond is critical for patient safety. In aerospace, the ability to join lightweight materials without compromising strength is particularly valuable, as it contributes to the overall performance and efficiency of aircraft. Overall, the versatility and efficiency of vibration friction machines make them indispensable in a wide range of applications, driving their demand across various industries.

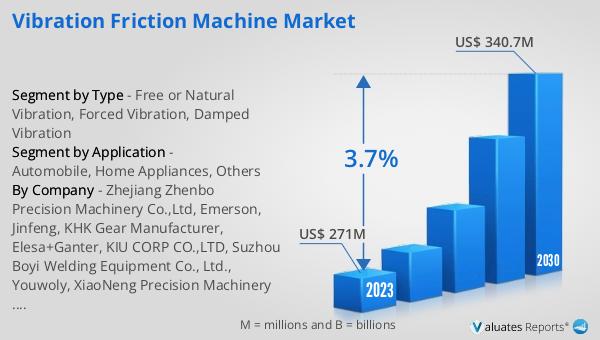

Global Vibration Friction Machine Market Outlook:

The global Vibration Friction Machine market was valued at US$ 271 million in 2023 and is anticipated to reach US$ 340.7 million by 2030, witnessing a CAGR of 3.7% during the forecast period 2024-2030. This growth can be attributed to several factors, including the increasing demand for lightweight and high-strength materials in various industries, advancements in technology, and the need for efficient and reliable bonding solutions. The market is characterized by a mix of established players and new entrants, all competing to offer innovative solutions to meet the evolving needs of their customers. As industries continue to seek ways to improve efficiency and performance, the demand for vibration friction machines is expected to grow, driving further advancements and innovations in the market.

| Report Metric | Details |

| Report Name | Vibration Friction Machine Market |

| Accounted market size in 2023 | US$ 271 million |

| Forecasted market size in 2030 | US$ 340.7 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zhejiang Zhenbo Precision Machinery Co.,Ltd, Emerson, Jinfeng, KHK Gear Manufacturer, Elesa+Ganter, KIU CORP CO.,LTD, Suzhou Boyi Welding Equipment Co., Ltd., Youwoly, XiaoNeng Precision Machinery Co., Ltd, Dukane, SOAIMC, TesT GmbH, Suzhou Keber Precision Machinery Co.,Ltd, Connie |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |