What is Global High Frequency Induction Welder Market?

The Global High Frequency Induction Welder Market is a specialized segment within the broader welding industry that focuses on the use of high-frequency electrical currents to heat and join materials. This technology is particularly effective for welding metals, especially those that are difficult to weld using traditional methods. High-frequency induction welding involves the use of an induction coil to generate an electromagnetic field, which induces eddy currents in the workpiece. These currents generate heat due to the material's electrical resistance, causing the metal to melt and fuse together. This method is highly efficient, precise, and capable of producing strong, high-quality welds. It is widely used in various industries, including automotive, aerospace, electronics, and construction, due to its ability to handle complex shapes and materials with minimal distortion. The market for high-frequency induction welders is driven by the increasing demand for advanced welding technologies that offer improved performance, energy efficiency, and cost-effectiveness. As industries continue to evolve and adopt new materials and manufacturing processes, the need for reliable and versatile welding solutions like high-frequency induction welders is expected to grow.

Ultrasonic Welding, Friction Welding, Hot Air in the Global High Frequency Induction Welder Market:

Ultrasonic welding, friction welding, and hot air welding are three distinct methods used within the Global High Frequency Induction Welder Market, each offering unique advantages and applications. Ultrasonic welding utilizes high-frequency ultrasonic vibrations to create frictional heat at the interface of the materials being joined. This method is particularly effective for welding plastics and thin metals, making it ideal for applications in the automotive, electronics, and medical device industries. The process is fast, clean, and does not require additional materials like adhesives or solder, resulting in strong, reliable bonds. Friction welding, on the other hand, involves the generation of heat through mechanical friction between the workpieces. This method is highly effective for joining dissimilar metals and is commonly used in the aerospace, automotive, and heavy machinery industries. Friction welding produces high-strength joints with minimal material waste and is capable of joining complex geometries. Hot air welding, also known as hot gas welding, uses a stream of hot air to melt the surfaces of the materials being joined. This method is widely used for welding thermoplastics and is commonly employed in the fabrication of plastic tanks, pipes, and membranes. Hot air welding is a versatile and cost-effective method that can be used for both manual and automated welding processes. Each of these welding methods offers unique benefits and is suited to specific applications, making them valuable tools within the Global High Frequency Induction Welder Market. As industries continue to seek advanced welding solutions that offer improved performance, efficiency, and versatility, the demand for these specialized welding methods is expected to grow.

Medical Equipment, Package, Auto Parts, Fishing Gear in the Global High Frequency Induction Welder Market:

The Global High Frequency Induction Welder Market finds extensive usage in various sectors, including medical equipment, packaging, auto parts, and fishing gear. In the medical equipment industry, high-frequency induction welders are used to join components of medical devices, such as surgical instruments, diagnostic equipment, and implants. The precision and reliability of this welding method ensure that the medical devices meet stringent quality and safety standards. In the packaging industry, high-frequency induction welders are employed to seal and join packaging materials, such as plastic films and foils. This method provides strong, airtight seals that protect the contents from contamination and extend shelf life. The automotive industry also benefits from high-frequency induction welding, as it is used to join various auto parts, including exhaust systems, fuel lines, and structural components. The ability to weld complex shapes and dissimilar materials with high precision and strength makes this method ideal for automotive applications. Additionally, the fishing gear industry utilizes high-frequency induction welders to join components of fishing rods, reels, and other equipment. The strong, durable welds produced by this method ensure that the fishing gear can withstand the harsh conditions of marine environments. Overall, the versatility and efficiency of high-frequency induction welding make it a valuable tool in these diverse industries, driving the growth of the Global High Frequency Induction Welder Market.

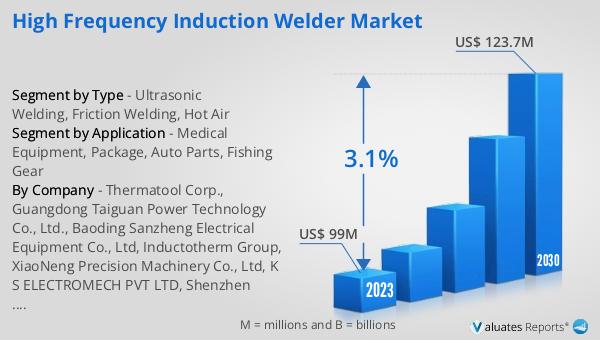

Global High Frequency Induction Welder Market Outlook:

The global High Frequency Induction Welder market was valued at US$ 99 million in 2023 and is anticipated to reach US$ 123.7 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This market growth is driven by the increasing demand for advanced welding technologies that offer improved performance, energy efficiency, and cost-effectiveness. High-frequency induction welding is particularly effective for welding metals, especially those that are difficult to weld using traditional methods. The technology involves the use of an induction coil to generate an electromagnetic field, which induces eddy currents in the workpiece, generating heat due to the material's electrical resistance. This method is highly efficient, precise, and capable of producing strong, high-quality welds. As industries continue to evolve and adopt new materials and manufacturing processes, the need for reliable and versatile welding solutions like high-frequency induction welders is expected to grow. The market for high-frequency induction welders is driven by the increasing demand for advanced welding technologies that offer improved performance, energy efficiency, and cost-effectiveness. As industries continue to evolve and adopt new materials and manufacturing processes, the need for reliable and versatile welding solutions like high-frequency induction welders is expected to grow.

| Report Metric | Details |

| Report Name | High Frequency Induction Welder Market |

| Accounted market size in 2023 | US$ 99 million |

| Forecasted market size in 2030 | US$ 123.7 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thermatool Corp., Guangdong Taiguan Power Technology Co., Ltd., Baoding Sanzheng Electrical Equipment Co., Ltd, Inductotherm Group, XiaoNeng Precision Machinery Co., Ltd, K S ELECTROMECH PVT LTD, Shenzhen double Ping Power Technology Co., Ltd, EFD Induction Inc., Forsstrom High Frequency AB, High Frequency Electronics Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |