What is Global Ethylene Propylene Copolymer Market?

The global Ethylene Propylene Copolymer market is a significant segment within the broader polymer industry. Ethylene Propylene Copolymer, often abbreviated as EPC, is a type of synthetic rubber that is known for its excellent resistance to heat, oxidation, and weathering. This makes it a highly sought-after material in various industries, including automotive, construction, and manufacturing. The market for EPC is driven by its versatile applications, which range from automotive parts like hoses and seals to roofing membranes and electrical insulation. The demand for EPC is also bolstered by its eco-friendly properties, as it can be recycled and has a lower environmental impact compared to other synthetic rubbers. The market is characterized by a diverse range of products and grades, each tailored to meet specific industrial requirements. With advancements in polymer technology and increasing investments in research and development, the global Ethylene Propylene Copolymer market is poised for sustained growth.

Solution Polymerization, Suspension Polymerization in the Global Ethylene Propylene Copolymer Market:

Solution Polymerization and Suspension Polymerization are two prominent methods used in the production of Ethylene Propylene Copolymer (EPC) within the global market. Solution Polymerization involves dissolving the monomers, ethylene and propylene, in a solvent along with a catalyst to initiate the polymerization process. This method allows for better control over the molecular weight distribution and the composition of the copolymer, resulting in a more uniform product. The solvent used in this process can be easily removed, leaving behind a high-purity EPC. This method is particularly advantageous for producing high-performance EPC grades that are used in demanding applications such as automotive seals and gaskets. On the other hand, Suspension Polymerization involves dispersing the monomers in a liquid medium, usually water, along with a catalyst. The polymerization occurs within the suspended droplets, forming small polymer beads. This method is known for its simplicity and cost-effectiveness, making it suitable for large-scale production. The resulting EPC from Suspension Polymerization is often used in applications where cost is a critical factor, such as in roofing membranes and general-purpose rubber goods. Both methods have their unique advantages and are chosen based on the specific requirements of the end-use application. The choice between Solution and Suspension Polymerization also depends on factors such as production scale, cost considerations, and the desired properties of the final product. As the global demand for EPC continues to grow, manufacturers are increasingly focusing on optimizing these polymerization techniques to enhance efficiency and product quality.

Sports Flooring, Playgrounds, Others in the Global Ethylene Propylene Copolymer Market:

The usage of Ethylene Propylene Copolymer (EPC) in sports flooring, playgrounds, and other areas highlights its versatility and durability. In sports flooring, EPC is used to create surfaces that are not only resilient but also provide excellent shock absorption and traction. This makes it ideal for indoor and outdoor sports facilities, where safety and performance are paramount. The material's resistance to UV radiation and weathering ensures that the flooring remains in good condition even after prolonged exposure to the elements. In playgrounds, EPC is used to create soft, impact-absorbing surfaces that reduce the risk of injuries from falls. The material's flexibility allows it to be molded into various shapes and designs, making playgrounds more engaging and fun for children. Additionally, EPC's non-toxic and hypoallergenic properties make it a safe choice for environments where children are present. Beyond sports flooring and playgrounds, EPC finds applications in a wide range of other areas. For instance, it is used in the construction industry for roofing membranes and waterproofing solutions due to its excellent resistance to water and weathering. In the automotive industry, EPC is used to manufacture hoses, seals, and gaskets that can withstand high temperatures and harsh conditions. The electrical industry also benefits from EPC's insulating properties, using it in cable insulation and other electrical components. The material's versatility extends to consumer goods as well, where it is used in products like footwear, toys, and household items. Overall, the diverse applications of EPC across various industries underscore its importance as a multifunctional material that meets a wide range of performance and safety requirements.

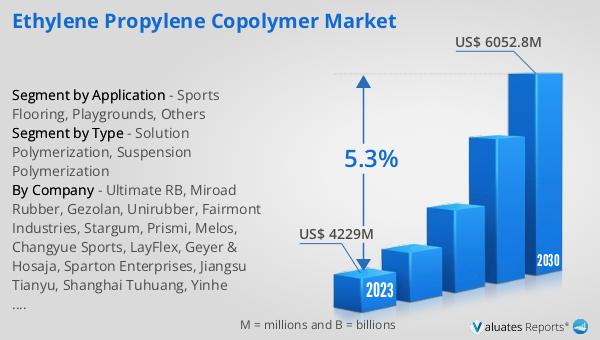

Global Ethylene Propylene Copolymer Market Outlook:

The global Ethylene Propylene Copolymer market was valued at US$ 4229 million in 2023 and is anticipated to reach US$ 6052.8 million by 2030, witnessing a CAGR of 5.3% during the forecast period from 2024 to 2030. This growth trajectory highlights the increasing demand for EPC across various industries, driven by its unique properties and versatile applications. The market's expansion is a testament to the material's ability to meet the evolving needs of industries such as automotive, construction, and consumer goods. As manufacturers continue to innovate and optimize production processes, the quality and performance of EPC are expected to improve, further boosting its adoption. The projected growth also reflects the ongoing investments in research and development aimed at enhancing the material's properties and expanding its application scope. With its combination of durability, flexibility, and environmental benefits, EPC is well-positioned to play a crucial role in the future of the polymer industry.

| Report Metric | Details |

| Report Name | Ethylene Propylene Copolymer Market |

| Accounted market size in 2023 | US$ 4229 million |

| Forecasted market size in 2030 | US$ 6052.8 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ultimate RB, Miroad Rubber, Gezolan, Unirubber, Fairmont Industries, Stargum, Prismi, Melos, Changyue Sports, LayFlex, Geyer & Hosaja, Sparton Enterprises, Jiangsu Tianyu, Shanghai Tuhuang, Yinhe Chemicals |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |