What is Global Rotary Fusion Welding Machine Market?

The Global Rotary Fusion Welding Machine Market refers to the worldwide industry focused on the production, distribution, and utilization of rotary fusion welding machines. These machines are specialized equipment used to join materials, typically metals, by applying heat and pressure in a rotational motion. The process involves melting the materials at the interface and then fusing them together to form a strong, durable bond. Rotary fusion welding machines are widely used in various industries, including automotive, aerospace, construction, and manufacturing, due to their ability to produce high-quality welds with precision and efficiency. The market encompasses a range of machine types, from manual to fully automated systems, catering to different welding needs and applications. As industries continue to advance and demand for high-performance welding solutions grows, the Global Rotary Fusion Welding Machine Market is expected to expand, driven by technological innovations and increasing adoption across various sectors.

Arc Welding, Laser Welding, Induction Welding, Oxyfuel Welding, Solid Reactant Welding in the Global Rotary Fusion Welding Machine Market:

Arc welding, laser welding, induction welding, oxyfuel welding, and solid reactant welding are various techniques used within the Global Rotary Fusion Welding Machine Market, each with its unique applications and advantages. Arc welding is one of the most common methods, utilizing an electric arc to melt and join metals. It is highly versatile and can be used on a wide range of materials and thicknesses. Laser welding, on the other hand, employs a concentrated laser beam to achieve precise and high-speed welds, making it ideal for applications requiring minimal thermal distortion and high accuracy. Induction welding uses electromagnetic induction to heat the materials, providing a clean and efficient welding process that is often used in the manufacturing of pipes and tubes. Oxyfuel welding, also known as gas welding, involves the combustion of oxygen and a fuel gas to produce a flame that melts the materials to be joined. This method is particularly useful for welding and cutting metals in various industrial applications. Solid reactant welding, or thermite welding, involves a chemical reaction between a metal oxide and aluminum powder to produce intense heat and molten metal, which is then used to join the materials. This technique is commonly used in rail welding and other heavy-duty applications where strong, durable welds are required. Each of these welding methods plays a crucial role in the Global Rotary Fusion Welding Machine Market, offering diverse solutions to meet the specific needs of different industries.

Aerospace, Hydraulic Equipments, Others in the Global Rotary Fusion Welding Machine Market:

The usage of Global Rotary Fusion Welding Machine Market in areas such as aerospace, hydraulic equipment, and others is extensive and varied. In the aerospace industry, rotary fusion welding machines are essential for manufacturing and repairing aircraft components. The precision and strength of the welds produced by these machines ensure the structural integrity and safety of critical parts such as engine components, airframes, and landing gear. The ability to create high-quality welds with minimal defects is crucial in aerospace applications, where even the smallest flaw can have significant consequences. In the hydraulic equipment sector, rotary fusion welding machines are used to fabricate and repair hydraulic cylinders, pumps, and valves. The robust and reliable welds produced by these machines ensure the proper functioning and longevity of hydraulic systems, which are vital for various industrial and construction applications. Additionally, rotary fusion welding machines are employed in other industries, including automotive, construction, and manufacturing, where they are used to join a wide range of materials and components. The versatility and efficiency of these machines make them indispensable tools for producing high-quality welds in diverse applications. As industries continue to evolve and demand for advanced welding solutions increases, the usage of rotary fusion welding machines is expected to grow, driven by their ability to meet the stringent requirements of modern manufacturing processes.

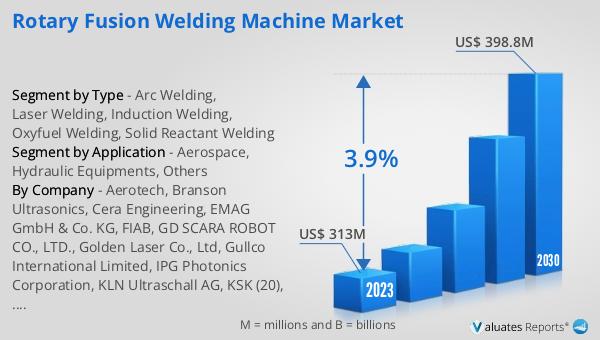

Global Rotary Fusion Welding Machine Market Outlook:

The global Rotary Fusion Welding Machine market was valued at US$ 313 million in 2023 and is anticipated to reach US$ 398.8 million by 2030, witnessing a CAGR of 3.9% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for rotary fusion welding machines across various industries. The projected growth rate indicates a positive trend, driven by factors such as technological advancements, rising industrialization, and the need for high-quality welding solutions. As industries continue to seek efficient and reliable welding methods, the adoption of rotary fusion welding machines is expected to rise, contributing to the overall expansion of the market. The increasing focus on automation and precision in manufacturing processes further supports the growth of this market, as rotary fusion welding machines offer the capability to produce consistent and accurate welds. The market's growth trajectory underscores the importance of these machines in meeting the evolving needs of industries worldwide, ensuring the production of durable and high-performance welded components.

| Report Metric | Details |

| Report Name | Rotary Fusion Welding Machine Market |

| Accounted market size in 2023 | US$ 313 million |

| Forecasted market size in 2030 | US$ 398.8 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Aerotech, Branson Ultrasonics, Cera Engineering, EMAG GmbH & Co. KG, FIAB, GD SCARA ROBOT CO., LTD., Golden Laser Co., Ltd, Gullco International Limited, IPG Photonics Corporation, KLN Ultraschall AG, KSK (20), KUKA AG, LEISTER Technologies AG, Miller Weldmaster, MSB GmbH & Co. KG, Ningbo Xinchang Machinery Co., Ltd., Prima CNC Machinery, ProByLas, Robolution, Roop Ultrasonix Ltd, Sir Meccanica S.p.A., SIRIUS ELECTRIC S.R.L., Sonics + Materials, Inc., Suzhou Suntop Laser Technology CO.,LTD, Weldlogic, Inc., WPI Taiwan, Zeltwanger Thermomanage |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |