What is Global CMP Silica Slurry Market?

The Global CMP Silica Slurry Market is a specialized segment within the semiconductor industry, focusing on the production and application of chemical mechanical planarization (CMP) silica slurry. CMP silica slurry is a critical material used in the semiconductor manufacturing process, particularly in the planarization or smoothing of silicon wafers. This slurry is composed of fine silica particles suspended in a liquid medium, which, when applied to a wafer surface, helps to remove excess material and achieve a flat, smooth surface. This process is essential for the production of integrated circuits (ICs) and other semiconductor devices, as it ensures the precision and uniformity required for high-performance electronic components. The market for CMP silica slurry is driven by the increasing demand for advanced semiconductor devices, the miniaturization of electronic components, and the need for higher efficiency and performance in electronic products. As the semiconductor industry continues to evolve, the importance of CMP silica slurry in achieving the desired level of precision and quality in wafer production remains paramount.

Colloidal Silica Slurry, Fumed Silica Slurry in the Global CMP Silica Slurry Market:

Colloidal silica slurry and fumed silica slurry are two primary types of CMP silica slurries used in the global market. Colloidal silica slurry consists of silica particles that are dispersed in a liquid medium, forming a stable colloidal suspension. These particles are typically spherical and have a uniform size distribution, which makes them highly effective in achieving a smooth and uniform surface during the CMP process. Colloidal silica slurry is known for its excellent stability, low defectivity, and high removal rate, making it a preferred choice for many semiconductor manufacturers. On the other hand, fumed silica slurry is made from fumed silica, which is produced by the flame hydrolysis of silicon tetrachloride. Fumed silica particles are characterized by their high surface area and unique morphology, which can enhance the polishing performance of the slurry. Fumed silica slurry is often used in applications where a higher level of precision and control is required, such as in the polishing of advanced semiconductor devices and high-performance integrated circuits. Both colloidal and fumed silica slurries play a crucial role in the CMP process, and their selection depends on the specific requirements of the application, including the type of wafer being polished, the desired surface finish, and the overall process efficiency. The global CMP silica slurry market is continuously evolving, with ongoing research and development efforts aimed at improving the performance and cost-effectiveness of these slurries. Innovations in slurry formulation, particle size control, and dispersion stability are driving the development of next-generation CMP silica slurries that can meet the increasingly stringent demands of the semiconductor industry. As the market grows, manufacturers are also focusing on sustainability and environmental impact, developing slurries that are not only effective but also environmentally friendly. This includes the use of renewable raw materials, reducing waste generation, and improving the recyclability of slurry components. The competition in the global CMP silica slurry market is intense, with several key players striving to gain a competitive edge through product innovation, strategic partnerships, and expansion into new markets. Companies are investing heavily in research and development to create slurries that offer superior performance, lower costs, and reduced environmental impact. Additionally, the market is witnessing a trend towards customization, with manufacturers offering tailored slurry solutions to meet the specific needs of their customers. This customer-centric approach is helping companies to build strong relationships with their clients and gain a deeper understanding of their requirements. Overall, the global CMP silica slurry market is poised for significant growth, driven by the increasing demand for advanced semiconductor devices, ongoing technological advancements, and a focus on sustainability and environmental responsibility.

Silicon Wafer Slurry, SiC Wafer Slurry, IC CMP Slurry, Others in the Global CMP Silica Slurry Market:

The usage of Global CMP Silica Slurry Market spans several critical areas, including silicon wafer slurry, SiC wafer slurry, IC CMP slurry, and others. Silicon wafer slurry is primarily used in the planarization of silicon wafers, which are the foundational substrates for most semiconductor devices. The CMP process involving silicon wafer slurry ensures that the wafer surface is smooth and free of defects, which is crucial for the subsequent layering and patterning steps in semiconductor manufacturing. This type of slurry is designed to provide a high removal rate, low defectivity, and excellent surface finish, making it ideal for the production of high-performance integrated circuits and other electronic components. SiC wafer slurry, on the other hand, is used in the polishing of silicon carbide (SiC) wafers, which are increasingly being used in power electronics and other high-performance applications. SiC wafers offer superior thermal conductivity, high breakdown voltage, and excellent chemical stability, making them suitable for use in harsh environments and high-power devices. The CMP process for SiC wafers requires a specialized slurry that can effectively remove material while minimizing surface damage and defects. IC CMP slurry is specifically formulated for the planarization of integrated circuits (ICs), which are the building blocks of modern electronic devices. This type of slurry is designed to achieve a high degree of precision and uniformity, ensuring that the ICs meet the stringent performance and reliability standards required by the semiconductor industry. IC CMP slurry is used in various stages of IC fabrication, including the polishing of metal and dielectric layers, to achieve the desired surface topography and electrical properties. Other applications of CMP silica slurry include the polishing of advanced packaging substrates, microelectromechanical systems (MEMS), and optoelectronic devices. These applications require slurries with specific properties tailored to the unique requirements of each device type. For example, advanced packaging substrates may require slurries with high selectivity and low defectivity to ensure the integrity of fine features and interconnects. MEMS devices, which are used in sensors, actuators, and other micro-scale applications, may require slurries with precise control over material removal and surface finish to achieve the desired performance characteristics. Optoelectronic devices, such as light-emitting diodes (LEDs) and laser diodes, may require slurries with specific optical properties to ensure optimal light emission and transmission. The versatility and adaptability of CMP silica slurry make it an indispensable material in the semiconductor industry, enabling the production of a wide range of high-performance electronic devices.

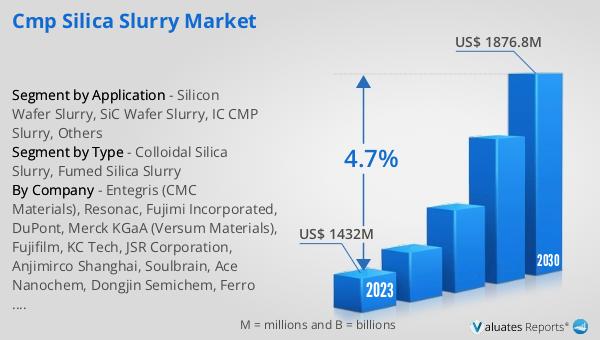

Global CMP Silica Slurry Market Outlook:

The global CMP Silica Slurry market was valued at US$ 1432 million in 2023 and is anticipated to reach US$ 1876.8 million by 2030, witnessing a CAGR of 4.7% during the forecast period 2024-2030. This growth is driven by the increasing demand for advanced semiconductor devices and the continuous advancements in CMP technology. The global market for semiconductors was estimated at US$ 579 billion in 2022 and is projected to reach US$ 790 billion by 2029, growing at a CAGR of 6% during the forecast period. The robust growth in the semiconductor market is a key driver for the CMP silica slurry market, as the demand for high-performance and miniaturized electronic components continues to rise. The increasing complexity of semiconductor devices, coupled with the need for higher efficiency and performance, is driving the adoption of advanced CMP silica slurries. These slurries play a crucial role in achieving the precision and uniformity required for the production of integrated circuits and other semiconductor devices. As the semiconductor industry continues to evolve, the importance of CMP silica slurry in achieving the desired level of precision and quality in wafer production remains paramount. The market is also witnessing a trend towards sustainability and environmental responsibility, with manufacturers focusing on developing slurries that are not only effective but also environmentally friendly. This includes the use of renewable raw materials, reducing waste generation, and improving the recyclability of slurry components. The competition in the global CMP silica slurry market is intense, with several key players striving to gain a competitive edge through product innovation, strategic partnerships, and expansion into new markets. Companies are investing heavily in research and development to create slurries that offer superior performance, lower costs, and reduced environmental impact. Additionally, the market is witnessing a trend towards customization, with manufacturers offering tailored slurry solutions to meet the specific needs of their customers. This customer-centric approach is helping companies to build strong relationships with their clients and gain a deeper understanding of their requirements. Overall, the global CMP silica slurry market is poised for significant growth, driven by the increasing demand for advanced semiconductor devices, ongoing technological advancements, and a focus on sustainability and environmental responsibility.

| Report Metric | Details |

| Report Name | CMP Silica Slurry Market |

| Accounted market size in 2023 | US$ 1432 million |

| Forecasted market size in 2030 | US$ 1876.8 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Entegris (CMC Materials), Resonac, Fujimi Incorporated, DuPont, Merck KGaA (Versum Materials), Fujifilm, KC Tech, JSR Corporation, Anjimirco Shanghai, Soulbrain, Ace Nanochem, Dongjin Semichem, Ferro (UWiZ Technology), WEC Group, SKC, Shanghai Xinanna Electronic Technology, Hubei Dinglong, Beijing Hangtian Saide |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |