What is Global Torch Cleaning Station Market?

The Global Torch Cleaning Station Market refers to the industry focused on the production, distribution, and utilization of torch cleaning stations. These stations are essential tools used in various industries to maintain and clean welding torches. Welding torches are prone to accumulating spatter and debris during the welding process, which can affect their performance and longevity. Torch cleaning stations help in removing these unwanted materials, ensuring that the torches function efficiently and have a longer lifespan. The market for these stations is driven by the increasing demand for high-quality welding processes in industries such as automotive, construction, and general manufacturing. As industries continue to seek ways to improve productivity and reduce downtime, the importance of maintaining clean and efficient welding equipment becomes paramount. This has led to a growing adoption of torch cleaning stations globally, making it a significant segment within the broader welding equipment market.

Manual Type, Automatic Type in the Global Torch Cleaning Station Market:

In the Global Torch Cleaning Station Market, there are primarily two types of stations: Manual and Automatic. Manual torch cleaning stations require the operator to physically handle the cleaning process. These stations are typically more affordable and are suitable for smaller operations or workshops where the volume of welding is not excessively high. They provide a straightforward solution for maintaining welding torches, though they can be labor-intensive and time-consuming. On the other hand, Automatic torch cleaning stations are designed to streamline the cleaning process with minimal human intervention. These stations use advanced technologies such as pneumatic or hydraulic systems to clean the torches efficiently. They are equipped with sensors and control systems that ensure precise cleaning, reducing the risk of human error. Automatic stations are ideal for large-scale industrial operations where the volume of welding is high, and efficiency is crucial. They help in reducing downtime and increasing productivity by ensuring that the torches are cleaned quickly and effectively. While they are more expensive than manual stations, the investment is often justified by the increased operational efficiency and reduced labor costs. Both types of torch cleaning stations play a vital role in maintaining the quality and efficiency of welding processes across various industries.

General Industry, Construction, Automotive, Energy Industry, Others in the Global Torch Cleaning Station Market:

The usage of Global Torch Cleaning Station Market spans across several key industries, including General Industry, Construction, Automotive, Energy Industry, and others. In the General Industry, torch cleaning stations are used to maintain welding torches that are employed in the manufacturing of various products. This ensures that the welding processes are efficient and the final products are of high quality. In the Construction industry, welding is a critical process used in building structures, bridges, and other infrastructure projects. Torch cleaning stations help in maintaining the welding equipment, ensuring that the welds are strong and reliable. In the Automotive industry, welding is used extensively in the manufacturing of vehicles. Clean and well-maintained welding torches are essential for producing high-quality welds that meet the stringent safety and performance standards of the automotive industry. The Energy Industry, which includes sectors such as oil and gas, power generation, and renewable energy, also relies heavily on welding processes. Torch cleaning stations help in maintaining the welding equipment used in the construction and maintenance of energy infrastructure. Other industries that use torch cleaning stations include aerospace, shipbuilding, and heavy machinery manufacturing. In all these industries, the primary benefit of using torch cleaning stations is the improved efficiency and longevity of welding equipment, which translates to better productivity and reduced operational costs.

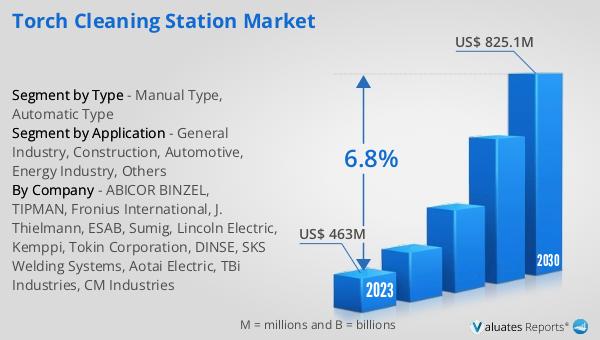

Global Torch Cleaning Station Market Outlook:

The global Torch Cleaning Station market was valued at US$ 463 million in 2023 and is anticipated to reach US$ 825.1 million by 2030, witnessing a CAGR of 6.8% during the forecast period 2024-2030. This significant growth is driven by the increasing demand for efficient and reliable welding processes across various industries. As companies continue to seek ways to improve productivity and reduce downtime, the adoption of torch cleaning stations is expected to rise. The market's growth is also supported by advancements in technology, which have led to the development of more efficient and user-friendly torch cleaning stations. These advancements have made it easier for industries to integrate these stations into their operations, further driving their adoption. Additionally, the growing focus on quality and safety in welding processes is expected to contribute to the market's growth. As industries continue to prioritize the maintenance of their welding equipment, the demand for torch cleaning stations is likely to increase, supporting the market's positive outlook.

| Report Metric | Details |

| Report Name | Torch Cleaning Station Market |

| Accounted market size in 2023 | US$ 463 million |

| Forecasted market size in 2030 | US$ 825.1 million |

| CAGR | 6.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABICOR BINZEL, TIPMAN, Fronius International, J. Thielmann, ESAB, Sumig, Lincoln Electric, Kemppi, Tokin Corporation, DINSE, SKS Welding Systems, Aotai Electric, TBi Industries, CM Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |