What is Global Robot Welding Torches Market?

The Global Robot Welding Torches Market refers to the worldwide industry that focuses on the production, distribution, and utilization of welding torches specifically designed for robotic welding systems. These torches are essential components in automated welding processes, which are increasingly being adopted across various industries due to their efficiency, precision, and ability to enhance productivity. The market encompasses a wide range of products, including different types of torches, accessories, and related equipment. It serves diverse sectors such as automotive, construction, general industry, and energy, among others. The growth of this market is driven by the rising demand for automation in manufacturing processes, technological advancements in welding equipment, and the need for high-quality, consistent welds. As industries continue to seek ways to improve operational efficiency and reduce labor costs, the adoption of robot welding torches is expected to increase, thereby propelling the market forward.

Air Cooled, Water Cooled in the Global Robot Welding Torches Market:

In the Global Robot Welding Torches Market, there are primarily two types of cooling mechanisms used for welding torches: air-cooled and water-cooled. Air-cooled welding torches rely on the surrounding air to dissipate the heat generated during the welding process. These torches are generally simpler in design, lighter, and more cost-effective compared to their water-cooled counterparts. They are suitable for applications where the welding duration is relatively short, and the heat generated is manageable without the need for additional cooling. Air-cooled torches are often used in light to medium-duty welding tasks and are favored for their ease of maintenance and lower operational costs. On the other hand, water-cooled welding torches use a continuous flow of water to cool the torch and the welding area. This cooling method is highly efficient and allows the torches to handle higher currents and longer welding durations without overheating. Water-cooled torches are typically used in heavy-duty welding applications where high heat is generated, such as in the automotive and construction industries. They are more complex and require a water cooling system, which adds to the initial setup cost and maintenance requirements. However, the benefits of prolonged torch life, consistent performance, and the ability to handle demanding welding tasks make water-cooled torches a preferred choice for many industrial applications. Both air-cooled and water-cooled torches play crucial roles in the Global Robot Welding Torches Market, catering to different needs and preferences based on the specific requirements of various industries.

General Industry, Construction, Automotive, Energy Industry, Others in the Global Robot Welding Torches Market:

The usage of Global Robot Welding Torches Market spans across several key industries, each benefiting from the efficiency and precision that robotic welding systems offer. In the general industry, robot welding torches are used for manufacturing a wide range of products, from household appliances to industrial machinery. The automation of welding processes in this sector helps in achieving consistent weld quality, reducing production time, and minimizing human error. In the construction industry, robot welding torches are employed in the fabrication of structural components, such as beams and columns, as well as in the assembly of prefabricated building sections. The use of robotic welding in construction enhances the speed and accuracy of welding tasks, leading to faster project completion and improved structural integrity. The automotive industry is one of the largest users of robot welding torches, utilizing them in the production of vehicle frames, exhaust systems, and other critical components. The high precision and repeatability of robotic welding ensure that automotive parts meet stringent quality standards, while also increasing production efficiency and reducing labor costs. In the energy industry, robot welding torches are used in the construction and maintenance of pipelines, power plants, and other energy infrastructure. The ability to perform high-quality welds in challenging environments, such as underwater or in hazardous areas, makes robotic welding an invaluable tool in this sector. Additionally, other industries, such as aerospace, shipbuilding, and electronics, also benefit from the use of robot welding torches. These industries require high precision and reliability in their welding processes, which robotic systems can provide. Overall, the adoption of robot welding torches across various industries highlights their versatility and the significant advantages they offer in terms of efficiency, quality, and cost savings.

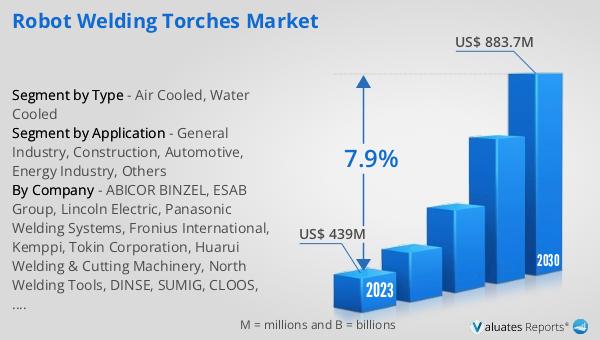

Global Robot Welding Torches Market Outlook:

The global Robot Welding Torches market was valued at US$ 439 million in 2023 and is anticipated to reach US$ 883.7 million by 2030, witnessing a CAGR of 7.9% during the forecast period 2024-2030. This significant growth reflects the increasing demand for automation in welding processes across various industries. The market's expansion is driven by the need for high-quality, consistent welds, and the desire to improve operational efficiency and reduce labor costs. As industries continue to adopt advanced technologies to stay competitive, the demand for robot welding torches is expected to rise. The market's growth is also supported by technological advancements in welding equipment, which enhance the performance and capabilities of robotic welding systems. With the ongoing trend towards automation and the continuous development of innovative welding solutions, the Global Robot Welding Torches Market is poised for substantial growth in the coming years.

| Report Metric | Details |

| Report Name | Robot Welding Torches Market |

| Accounted market size in 2023 | US$ 439 million |

| Forecasted market size in 2030 | US$ 883.7 million |

| CAGR | 7.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABICOR BINZEL, ESAB Group, Lincoln Electric, Panasonic Welding Systems, Fronius International, Kemppi, Tokin Corporation, Huarui Welding & Cutting Machinery, North Welding Tools, DINSE, SUMIG, CLOOS, Migatronic, SKS Welding Systems, Parker Torchology, EWM, Lorch |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |