What is Global Knitted Mesh Mist Eliminators Market?

The global Knitted Mesh Mist Eliminators market is a specialized segment within the broader industrial filtration industry. Knitted mesh mist eliminators are devices used to remove liquid droplets from gas streams, ensuring that the gas is free from contaminants. These devices are essential in various industrial processes where the purity of the gas is crucial. The market for these products is driven by their widespread application in industries such as oil and gas, chemical processing, power generation, and gas processing. The demand for knitted mesh mist eliminators is growing due to the increasing need for efficient and reliable filtration systems that can handle high volumes of gas and liquid mixtures. These devices are known for their high efficiency, durability, and ability to operate under extreme conditions, making them a preferred choice in many industrial applications. The global market is characterized by a mix of established players and new entrants, all competing to offer innovative solutions to meet the evolving needs of their customers. The market is also influenced by regulatory standards and environmental concerns, which drive the adoption of advanced filtration technologies.

Metal Material, Non-Metal Material in the Global Knitted Mesh Mist Eliminators Market:

In the global Knitted Mesh Mist Eliminators market, materials play a crucial role in determining the efficiency and durability of the products. The two primary categories of materials used in these devices are metal and non-metal materials. Metal materials, such as stainless steel, nickel, and titanium, are commonly used due to their high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures. Stainless steel is particularly popular because of its excellent mechanical properties and resistance to rust and chemical corrosion. Nickel and titanium are used in more specialized applications where higher resistance to corrosion and extreme temperatures is required. These metal materials are often chosen for applications in harsh environments, such as in the oil and gas industry, where the conditions can be particularly demanding. On the other hand, non-metal materials, such as plastic and fiberglass, are also used in the production of knitted mesh mist eliminators. These materials are chosen for their lightweight properties, cost-effectiveness, and resistance to certain chemicals. Plastic materials, such as polypropylene and polyethylene, are commonly used in applications where the operating conditions are less severe, and where cost considerations are a priority. Fiberglass is another non-metal material that is valued for its high strength-to-weight ratio and resistance to a wide range of chemicals. The choice between metal and non-metal materials depends on various factors, including the specific requirements of the application, the operating environment, and the cost considerations. In some cases, a combination of metal and non-metal materials may be used to achieve the desired balance of performance and cost. The global market for knitted mesh mist eliminators is thus characterized by a diverse range of materials, each offering unique advantages and catering to different industrial needs. The ongoing advancements in material science and engineering are expected to further enhance the performance and application range of these devices, driving their adoption across various industries.

Oil & Gas, Chemical Industry, Power, Gas Processing, Others in the Global Knitted Mesh Mist Eliminators Market:

The global Knitted Mesh Mist Eliminators market finds extensive usage across several key industries, including oil and gas, chemical industry, power generation, gas processing, and others. In the oil and gas industry, these devices are crucial for removing liquid droplets from gas streams, ensuring the purity of the gas and protecting downstream equipment from corrosion and damage. They are used in various stages of oil and gas production, including drilling, refining, and transportation, where the presence of liquid contaminants can significantly impact the efficiency and safety of operations. In the chemical industry, knitted mesh mist eliminators are used to remove liquid droplets from process gases, ensuring the purity of the final product and preventing contamination. They are commonly used in processes such as distillation, absorption, and stripping, where the separation of liquid and gas phases is essential for achieving the desired product quality. In the power generation industry, these devices are used to remove liquid droplets from steam and other process gases, ensuring the efficient operation of turbines and other equipment. They help to prevent corrosion and scaling, which can reduce the efficiency and lifespan of power generation equipment. In gas processing, knitted mesh mist eliminators are used to remove liquid contaminants from natural gas and other process gases, ensuring the purity of the gas and protecting downstream equipment. They are used in various stages of gas processing, including compression, dehydration, and sweetening, where the presence of liquid contaminants can impact the efficiency and safety of operations. Other industries that use knitted mesh mist eliminators include pharmaceuticals, food and beverage, and water treatment, where the removal of liquid contaminants from gas streams is essential for achieving the desired product quality and ensuring the efficient operation of equipment. The versatility and efficiency of knitted mesh mist eliminators make them a preferred choice in a wide range of industrial applications, driving their demand in the global market.

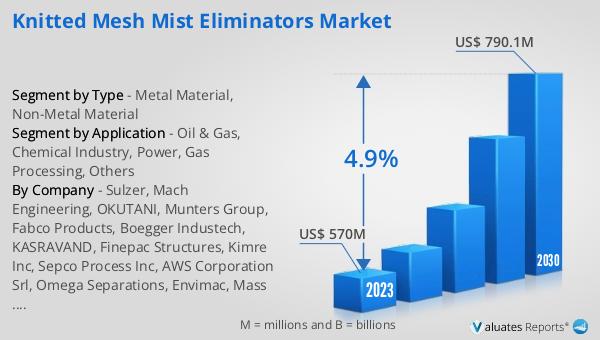

Global Knitted Mesh Mist Eliminators Market Outlook:

The global Knitted Mesh Mist Eliminators market was valued at $570 million in 2023 and is projected to reach $790.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for efficient and reliable filtration systems across various industries, including oil and gas, chemical processing, power generation, and gas processing. The market is characterized by a mix of established players and new entrants, all competing to offer innovative solutions to meet the evolving needs of their customers. The adoption of advanced filtration technologies, driven by regulatory standards and environmental concerns, is also contributing to the growth of the market. The increasing focus on improving operational efficiency and reducing maintenance costs is further driving the demand for high-performance knitted mesh mist eliminators. The market is expected to witness significant growth in the coming years, driven by the ongoing advancements in material science and engineering, which are enhancing the performance and application range of these devices. The global market for knitted mesh mist eliminators is thus poised for steady growth, driven by the increasing demand for efficient and reliable filtration systems across various industries.

| Report Metric | Details |

| Report Name | Knitted Mesh Mist Eliminators Market |

| Accounted market size in 2023 | US$ 570 million |

| Forecasted market size in 2030 | US$ 790.1 million |

| CAGR | 4.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sulzer, Mach Engineering, OKUTANI, Munters Group, Fabco Products, Boegger Industech, KASRAVAND, Finepac Structures, Kimre Inc, Sepco Process Inc, AWS Corporation Srl, Omega Separations, Envimac, Mass Transfer Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |