What is Global Metal Anti-rust and Anti-corrosion Coating Market?

The Global Metal Anti-rust and Anti-corrosion Coating Market is a specialized segment within the broader coatings industry, focusing on products designed to protect metal surfaces from rust and corrosion. These coatings are essential in extending the lifespan of metal structures and components by preventing the oxidative processes that lead to rust and corrosion. The market encompasses a variety of coating types, each formulated to address specific environmental and operational challenges. These coatings are used across numerous industries, including construction, automotive, marine, and manufacturing, where metal components are exposed to harsh conditions. The demand for these coatings is driven by the need to maintain the integrity and functionality of metal structures, reduce maintenance costs, and comply with stringent environmental regulations. The market is characterized by continuous innovation, with manufacturers developing advanced formulations that offer improved performance, durability, and environmental compliance.

Epoxy, Polyester, Polyurethane, Vinyl Ester, Others in the Global Metal Anti-rust and Anti-corrosion Coating Market:

Epoxy, polyester, polyurethane, vinyl ester, and other coatings play crucial roles in the Global Metal Anti-rust and Anti-corrosion Coating Market, each offering unique properties and benefits. Epoxy coatings are known for their excellent adhesion, chemical resistance, and durability, making them ideal for industrial applications where metal surfaces are exposed to harsh chemicals and mechanical wear. They are commonly used in the marine, oil and gas, and manufacturing sectors. Polyester coatings, on the other hand, are valued for their flexibility, UV resistance, and aesthetic appeal. These coatings are often used in architectural applications, where both protection and appearance are important. Polyurethane coatings offer a balance of flexibility, toughness, and chemical resistance, making them suitable for a wide range of applications, including automotive and aerospace industries. Vinyl ester coatings are known for their superior resistance to chemicals and moisture, making them ideal for use in environments where metal surfaces are exposed to aggressive chemicals and high humidity. Other coatings in this market include acrylics, alkyds, and fluoropolymers, each offering specific advantages depending on the application requirements. Acrylic coatings, for example, are known for their fast-drying properties and UV resistance, making them suitable for outdoor applications. Alkyd coatings offer good adhesion and durability, making them a cost-effective option for general-purpose applications. Fluoropolymer coatings, on the other hand, provide exceptional resistance to chemicals, heat, and weathering, making them ideal for high-performance applications in harsh environments. The choice of coating depends on various factors, including the type of metal, the environmental conditions, and the specific performance requirements. Manufacturers in this market are continuously innovating to develop coatings that offer improved performance, sustainability, and cost-effectiveness.

Architecture, Ship, Petrochemical, Manufacturing, Others in the Global Metal Anti-rust and Anti-corrosion Coating Market:

The usage of Global Metal Anti-rust and Anti-corrosion Coating Market spans across various sectors, including architecture, shipbuilding, petrochemical, manufacturing, and others. In architecture, these coatings are used to protect structural steel and metal components from rust and corrosion, ensuring the longevity and safety of buildings and infrastructure. They are applied to bridges, skyscrapers, and other structures exposed to the elements, where they provide a protective barrier against moisture, pollutants, and other corrosive agents. In the shipbuilding industry, anti-rust and anti-corrosion coatings are essential for protecting the hulls and other metal components of ships from the harsh marine environment. These coatings help prevent the degradation of metal surfaces caused by saltwater, humidity, and marine organisms, thereby extending the service life of vessels and reducing maintenance costs. In the petrochemical industry, these coatings are used to protect pipelines, storage tanks, and other metal equipment from the corrosive effects of chemicals and hydrocarbons. They help maintain the integrity of critical infrastructure, ensuring safe and efficient operations. In the manufacturing sector, anti-rust and anti-corrosion coatings are applied to machinery, equipment, and metal parts to prevent rust and corrosion, thereby enhancing their durability and performance. These coatings are also used in the automotive industry to protect car bodies and components from rust and corrosion, ensuring the longevity and aesthetic appeal of vehicles. Other applications of these coatings include aerospace, where they are used to protect aircraft components from corrosion, and the energy sector, where they are applied to wind turbines, solar panels, and other metal structures exposed to harsh environmental conditions. Overall, the usage of anti-rust and anti-corrosion coatings is critical in various industries to protect metal surfaces, extend the lifespan of assets, and reduce maintenance costs.

Global Metal Anti-rust and Anti-corrosion Coating Market Outlook:

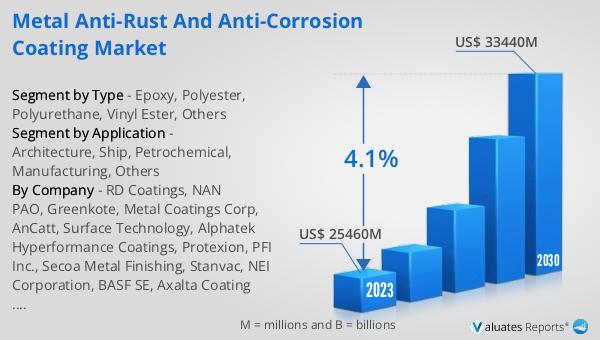

The global Metal Antirust and Anticorrosion Coating market was valued at US$ 25,460 million in 2023 and is anticipated to reach US$ 33,440 million by 2030, witnessing a CAGR of 4.1% during the forecast period from 2024 to 2030. This market growth reflects the increasing demand for protective coatings across various industries, driven by the need to enhance the durability and longevity of metal structures and components. The rising awareness about the benefits of anti-rust and anti-corrosion coatings, coupled with stringent environmental regulations, is also contributing to the market's expansion. Manufacturers are focusing on developing advanced coatings that offer superior performance, sustainability, and cost-effectiveness to meet the evolving needs of end-users. The market is characterized by continuous innovation, with companies investing in research and development to create new formulations that provide enhanced protection against rust and corrosion. The growing adoption of these coatings in emerging economies, where industrialization and infrastructure development are on the rise, is further fueling market growth. Overall, the global Metal Antirust and Anticorrosion Coating market is poised for significant growth in the coming years, driven by the increasing demand for high-performance coatings that protect metal surfaces from rust and corrosion.

| Report Metric | Details |

| Report Name | Metal Anti-rust and Anti-corrosion Coating Market |

| Accounted market size in 2023 | US$ 25460 million |

| Forecasted market size in 2030 | US$ 33440 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | RD Coatings, NAN PAO, Greenkote, Metal Coatings Corp, AnCatt, Surface Technology, Alphatek Hyperformance Coatings, Protexion, PFI Inc., Secoa Metal Finishing, Stanvac, NEI Corporation, BASF SE, Axalta Coating Systems LLC, EonCoat, Hempel A/S, Jotun, Nippon Paint Holdings Co. Ltd, Sika AG, The Sherwin-Williams Company, Akzo Nobel NV |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |