What is Global Steel Anticorrosive Coating Market?

The Global Steel Anticorrosive Coating Market is a specialized segment within the broader coatings industry, focusing on products designed to protect steel structures from corrosion. Corrosion is a natural process that deteriorates metal when it reacts with environmental elements like moisture, oxygen, and chemicals. This market encompasses a variety of coatings that are applied to steel surfaces to prevent or slow down this degradation process. These coatings are essential in extending the lifespan of steel structures, reducing maintenance costs, and ensuring safety. The market includes various types of coatings, each with unique properties and applications, tailored to meet the specific needs of different industries such as construction, marine, petrochemical, and manufacturing. The demand for these coatings is driven by the need to protect valuable infrastructure and equipment from the damaging effects of corrosion, which can lead to significant financial losses and safety hazards if not properly managed. The market is characterized by continuous innovation and development of new formulations to enhance performance, durability, and environmental compliance.

Fluorocarbon Topcoat, Acrylic Amino Polyurethane, Epoxy Anti-rust Paint, Inorganic Anti-corrosion Coating, Others in the Global Steel Anticorrosive Coating Market:

Fluorocarbon Topcoat is a high-performance coating known for its excellent resistance to weathering, chemicals, and UV radiation. It forms a durable, glossy finish that not only protects steel surfaces but also enhances their aesthetic appeal. This type of coating is often used in environments where long-term durability and appearance are critical, such as in architectural structures and high-end industrial applications. Acrylic Amino Polyurethane is another popular choice in the Global Steel Anticorrosive Coating Market. It combines the flexibility and durability of polyurethane with the quick-drying properties of acrylics, making it suitable for a wide range of applications. This coating provides excellent resistance to abrasion, chemicals, and weathering, making it ideal for use in harsh industrial environments. Epoxy Anti-rust Paint is a widely used coating known for its strong adhesion and excellent resistance to moisture, chemicals, and abrasion. It forms a tough, protective barrier on steel surfaces, making it ideal for use in marine, industrial, and infrastructure applications. Inorganic Anti-corrosion Coating, on the other hand, offers superior heat resistance and durability. These coatings are often used in high-temperature environments and provide long-lasting protection against corrosion. They are commonly used in petrochemical plants, power plants, and other industrial facilities where extreme conditions are prevalent. Other types of coatings in the market include zinc-rich primers, which provide sacrificial protection to steel surfaces, and hybrid coatings that combine the benefits of different coating technologies to offer enhanced performance. Each type of coating has its unique advantages and is selected based on the specific requirements of the application, such as the environmental conditions, the type of steel, and the desired lifespan of the coating. The continuous development of new formulations and technologies in the Global Steel Anticorrosive Coating Market ensures that there are always new solutions available to meet the evolving needs of various industries.

Architecture, Ship, Petrochemical, Manufacturing, Others in the Global Steel Anticorrosive Coating Market:

The usage of Global Steel Anticorrosive Coating Market spans across various sectors, each with its unique requirements and challenges. In architecture, these coatings are essential for protecting steel structures such as bridges, buildings, and monuments from the damaging effects of weathering and pollution. The coatings not only enhance the durability and lifespan of these structures but also improve their aesthetic appeal by providing a smooth, glossy finish. In the shipbuilding industry, anticorrosive coatings are crucial for protecting vessels from the harsh marine environment. The constant exposure to saltwater, humidity, and varying temperatures can cause severe corrosion, leading to structural damage and increased maintenance costs. These coatings provide a protective barrier that prevents rust and corrosion, ensuring the longevity and safety of the ships. In the petrochemical industry, steel anticorrosive coatings are used to protect pipelines, storage tanks, and other equipment from the corrosive effects of chemicals and extreme temperatures. The coatings help in maintaining the integrity of the infrastructure, preventing leaks and spills that can have catastrophic environmental and financial consequences. In the manufacturing sector, these coatings are applied to machinery, tools, and other steel components to protect them from wear and tear, chemical exposure, and environmental factors. This not only extends the lifespan of the equipment but also ensures smooth and efficient operations. Other areas where these coatings are used include automotive, aerospace, and energy sectors, where the protection of steel components is critical for safety, performance, and cost-efficiency. The versatility and effectiveness of steel anticorrosive coatings make them an indispensable part of various industries, helping to protect valuable assets and infrastructure from the damaging effects of corrosion.

Global Steel Anticorrosive Coating Market Outlook:

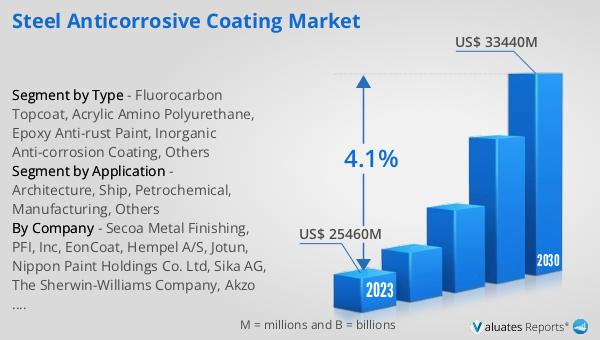

The global Steel Anticorrosive Coating market, valued at US$ 25,460 million in 2023, is projected to grow significantly, reaching an estimated US$ 33,440 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. This upward trend highlights the increasing demand for effective corrosion protection solutions across various industries. The rising awareness about the economic and safety implications of corrosion, coupled with the need to extend the lifespan of steel structures and equipment, is driving the market's expansion. Innovations in coating technologies and the development of environmentally friendly formulations are also contributing to the market's growth. As industries continue to invest in infrastructure and equipment, the demand for high-performance anticorrosive coatings is expected to rise, ensuring the market's steady growth in the coming years.

| Report Metric | Details |

| Report Name | Steel Anticorrosive Coating Market |

| Accounted market size in 2023 | US$ 25460 million |

| Forecasted market size in 2030 | US$ 33440 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Secoa Metal Finishing, PFI, Inc, EonCoat, Hempel A/S, Jotun, Nippon Paint Holdings Co. Ltd, Sika AG, The Sherwin-Williams Company, Akzo Nobel NV, RD Coatings, NAN PAO, Metal Coatings Corp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |