What is Global UV and Light-curing Adhesive Market?

The Global UV and Light-curing Adhesive Market is a specialized segment within the broader adhesives industry, focusing on adhesives that cure or harden when exposed to ultraviolet (UV) light or visible light. These adhesives are known for their rapid curing times, strong bonding capabilities, and versatility across various materials. They are widely used in industries such as electronics, automotive, medical devices, and more. The market for these adhesives is driven by the increasing demand for high-performance bonding solutions that can withstand harsh environmental conditions and provide long-lasting durability. Additionally, the growing trend towards miniaturization in electronics and the need for precise and reliable bonding solutions in medical devices are further propelling the market's growth. The UV and light-curing adhesives offer several advantages, including reduced processing times, lower energy consumption, and the ability to bond a wide range of substrates, making them an attractive choice for manufacturers looking to improve efficiency and product performance.

Adhesive Tape, Double Sided Tape, Liquid Glue in the Global UV and Light-curing Adhesive Market:

Adhesive tapes, double-sided tapes, and liquid glues are integral components of the Global UV and Light-curing Adhesive Market. Adhesive tapes are versatile and easy-to-use bonding solutions that come in various forms, including single-sided and double-sided tapes. Single-sided tapes have adhesive on one side and are commonly used for applications such as sealing, masking, and surface protection. Double-sided tapes, on the other hand, have adhesive on both sides and are used for mounting, bonding, and joining applications where a strong, permanent bond is required. These tapes are often used in industries such as automotive, electronics, and construction due to their ability to provide a clean and efficient bonding solution without the need for additional tools or equipment. Liquid glues, including UV and light-curing adhesives, offer a different approach to bonding. These adhesives are applied in liquid form and cure or harden when exposed to UV light or visible light. This curing process is rapid, often taking just a few seconds to complete, making it ideal for high-speed manufacturing processes. Liquid glues are known for their strong bonding capabilities and versatility, as they can bond a wide range of materials, including metals, plastics, glass, and ceramics. In the electronics industry, UV and light-curing adhesives are used for applications such as encapsulating components, securing wires, and bonding display screens. In the automotive industry, they are used for bonding interior and exterior components, as well as for structural bonding applications. The medical industry also benefits from the use of UV and light-curing adhesives, particularly in the manufacturing of medical devices and equipment. These adhesives provide strong, reliable bonds that can withstand sterilization processes and harsh environmental conditions. They are used for applications such as assembling medical devices, bonding catheters, and securing surgical instruments. The ability to cure quickly and provide a strong bond makes them an ideal choice for medical applications where precision and reliability are critical. In addition to adhesive tapes and liquid glues, the Global UV and Light-curing Adhesive Market also includes other forms of adhesives, such as gels and pastes. These adhesives offer similar benefits in terms of rapid curing and strong bonding capabilities but are formulated to provide different handling and application characteristics. For example, gels and pastes may be used in applications where a thicker, more viscous adhesive is required to fill gaps or provide additional structural support. Overall, the Global UV and Light-curing Adhesive Market encompasses a wide range of adhesive products, each designed to meet the specific needs of different industries and applications. The versatility, rapid curing times, and strong bonding capabilities of these adhesives make them an attractive choice for manufacturers looking to improve efficiency and product performance. As industries continue to evolve and demand more advanced bonding solutions, the market for UV and light-curing adhesives is expected to grow, driven by the need for high-performance, reliable, and efficient bonding solutions.

Electronic Equipment and Components, Automotive, Medical, Plastics and Resins, Jewelry and Accessories, Others in the Global UV and Light-curing Adhesive Market:

The Global UV and Light-curing Adhesive Market finds extensive usage across various industries, including electronic equipment and components, automotive, medical, plastics and resins, jewelry and accessories, and others. In the electronics industry, these adhesives are crucial for assembling and securing components such as circuit boards, sensors, and display screens. The rapid curing times and strong bonding capabilities of UV and light-curing adhesives make them ideal for high-speed manufacturing processes, ensuring that electronic devices are assembled quickly and efficiently. Additionally, these adhesives provide excellent resistance to environmental factors such as heat, moisture, and chemicals, ensuring the longevity and reliability of electronic devices. In the automotive industry, UV and light-curing adhesives are used for a wide range of applications, including bonding interior and exterior components, securing trim and moldings, and assembling structural parts. These adhesives provide strong, durable bonds that can withstand the harsh conditions of automotive environments, such as temperature fluctuations, vibrations, and exposure to chemicals. The ability to cure quickly and provide a reliable bond makes them an attractive choice for automotive manufacturers looking to improve production efficiency and product performance. The medical industry also relies heavily on UV and light-curing adhesives for the assembly and bonding of medical devices and equipment. These adhesives are used for applications such as bonding catheters, assembling surgical instruments, and securing components in diagnostic equipment. The rapid curing times and strong bonding capabilities of UV and light-curing adhesives ensure that medical devices are assembled quickly and reliably, meeting the stringent quality and safety standards required in the medical field. Additionally, these adhesives are biocompatible and can withstand sterilization processes, making them suitable for use in medical applications. In the plastics and resins industry, UV and light-curing adhesives are used for bonding and assembling plastic components, as well as for repairing and reinforcing plastic parts. These adhesives provide strong, durable bonds that can withstand the stresses and strains of everyday use, ensuring the longevity and reliability of plastic products. The ability to bond a wide range of plastic materials, including rigid and flexible plastics, makes UV and light-curing adhesives a versatile choice for manufacturers in the plastics and resins industry. The jewelry and accessories industry also benefits from the use of UV and light-curing adhesives, particularly for applications such as bonding gemstones, securing clasps, and assembling intricate designs. These adhesives provide strong, reliable bonds that can withstand the wear and tear of everyday use, ensuring that jewelry and accessories remain intact and secure. The rapid curing times and precision application capabilities of UV and light-curing adhesives make them an ideal choice for jewelry manufacturers looking to improve production efficiency and product quality. Other industries that utilize UV and light-curing adhesives include aerospace, construction, and consumer goods. In the aerospace industry, these adhesives are used for bonding and assembling components in aircraft and spacecraft, providing strong, durable bonds that can withstand the extreme conditions of aerospace environments. In the construction industry, UV and light-curing adhesives are used for applications such as bonding glass, securing tiles, and assembling structural components. The consumer goods industry also benefits from the use of these adhesives for applications such as assembling household appliances, bonding packaging materials, and securing components in electronic devices. Overall, the Global UV and Light-curing Adhesive Market plays a crucial role in a wide range of industries, providing high-performance bonding solutions that improve efficiency, reliability, and product quality. The versatility, rapid curing times, and strong bonding capabilities of these adhesives make them an attractive choice for manufacturers looking to meet the demands of modern production processes and deliver high-quality products to consumers.

Global UV and Light-curing Adhesive Market Outlook:

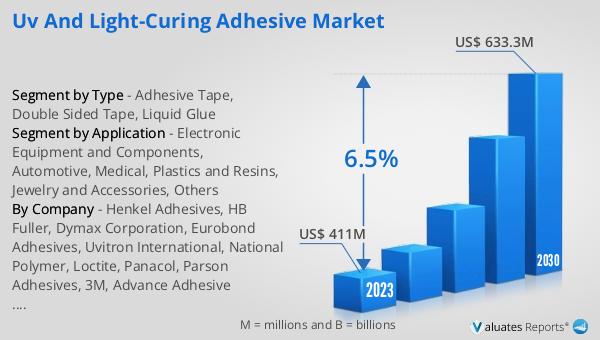

The global UV and light-curing adhesive market was valued at $411 million in 2023 and is projected to grow to $633.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance bonding solutions across various industries, including electronics, automotive, medical, and more. The rapid curing times, strong bonding capabilities, and versatility of UV and light-curing adhesives make them an attractive choice for manufacturers looking to improve efficiency and product performance. Additionally, the growing trend towards miniaturization in electronics and the need for precise and reliable bonding solutions in medical devices are further propelling the market's growth. As industries continue to evolve and demand more advanced bonding solutions, the market for UV and light-curing adhesives is expected to expand, driven by the need for high-performance, reliable, and efficient bonding solutions.

| Report Metric | Details |

| Report Name | UV and Light-curing Adhesive Market |

| Accounted market size in 2023 | US$ 411 million |

| Forecasted market size in 2030 | US$ 633.3 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel Adhesives, HB Fuller, Dymax Corporation, Eurobond Adhesives, Uvitron International, National Polymer, Loctite, Panacol, Parson Adhesives, 3M, Advance Adhesive Systems, Permabond, DeepMaterial, Hernon, Polytec PT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |