What is Global Panel Mount Solid State Relays (SSR) Market?

The Global Panel Mount Solid State Relays (SSR) Market is a specialized segment within the broader electronics and electrical components industry. Solid State Relays (SSRs) are electronic switching devices that use semiconductor properties to switch on or off when an external voltage is applied. Unlike traditional electromechanical relays, SSRs have no moving parts, which makes them more reliable and longer-lasting. The panel mount type refers to SSRs that are designed to be mounted on panels, making them suitable for various industrial and commercial applications. These relays are used in situations where high reliability and fast switching are required, such as in industrial automation, HVAC systems, and power distribution. The market for these devices is driven by the increasing demand for energy-efficient and reliable switching solutions across different sectors. As industries continue to automate and seek more efficient ways to manage electrical loads, the demand for panel mount SSRs is expected to grow. The market is characterized by technological advancements, with manufacturers focusing on developing SSRs that offer better performance, higher load capacities, and enhanced durability.

AC Solid State Relays, DC Solid State Relays in the Global Panel Mount Solid State Relays (SSR) Market:

AC Solid State Relays and DC Solid State Relays are two primary types of SSRs used in the Global Panel Mount Solid State Relays Market. AC Solid State Relays are designed to control AC loads. They are commonly used in applications where alternating current is the primary power source. These relays are ideal for controlling high-power AC loads such as motors, heaters, and lighting systems. AC SSRs offer several advantages over traditional mechanical relays, including faster switching times, longer lifespan, and reduced electromagnetic interference. They are often used in industrial automation, HVAC systems, and lighting control systems. On the other hand, DC Solid State Relays are used to control DC loads. They are suitable for applications where direct current is used, such as in battery-powered systems, solar power systems, and DC motor control. DC SSRs provide precise control over DC loads, making them ideal for applications that require accurate and reliable switching. They are commonly used in renewable energy systems, automotive applications, and telecommunications equipment. Both AC and DC SSRs are integral to the Global Panel Mount Solid State Relays Market, providing reliable and efficient switching solutions for a wide range of applications. The choice between AC and DC SSRs depends on the specific requirements of the application, including the type of load, power source, and desired performance characteristics. As technology continues to advance, manufacturers are developing SSRs with enhanced features, such as higher load capacities, improved thermal management, and advanced protection mechanisms. These advancements are driving the growth of the Global Panel Mount Solid State Relays Market, as industries seek more efficient and reliable switching solutions to meet their evolving needs.

Industrial Equipment, Home Appliance, Building Automation, Power & Energy, Others in the Global Panel Mount Solid State Relays (SSR) Market:

The Global Panel Mount Solid State Relays (SSR) Market finds extensive usage across various sectors, including industrial equipment, home appliances, building automation, power and energy, and others. In the industrial equipment sector, SSRs are used to control and manage electrical loads in machinery and equipment. They provide reliable and efficient switching solutions for motors, heaters, and other high-power devices, ensuring smooth and uninterrupted operation. In home appliances, SSRs are used to control heating elements, motors, and other components, providing precise and reliable switching for improved performance and energy efficiency. In building automation, SSRs are used to control lighting, HVAC systems, and other electrical loads, providing efficient and reliable switching solutions for improved energy management and comfort. In the power and energy sector, SSRs are used in renewable energy systems, power distribution, and other applications, providing reliable and efficient switching solutions for improved performance and energy efficiency. In other sectors, SSRs are used in telecommunications equipment, automotive applications, and other areas where reliable and efficient switching solutions are required. The versatility and reliability of SSRs make them an ideal choice for a wide range of applications, driving the growth of the Global Panel Mount Solid State Relays Market. As industries continue to seek more efficient and reliable switching solutions, the demand for SSRs is expected to grow, further driving the growth of the market.

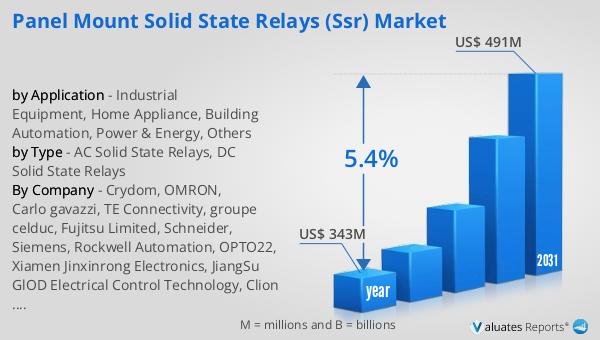

Global Panel Mount Solid State Relays (SSR) Market Outlook:

The global market for Panel Mount Solid State Relays (SSR) was valued at approximately $343 million in 2024. It is anticipated to expand to a revised size of around $491 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. This growth is indicative of the increasing demand for reliable and efficient switching solutions across various industries. The market's expansion is driven by technological advancements and the growing need for energy-efficient solutions in industrial automation, building automation, and other sectors. As industries continue to automate and seek more efficient ways to manage electrical loads, the demand for panel mount SSRs is expected to grow. The market is characterized by technological advancements, with manufacturers focusing on developing SSRs that offer better performance, higher load capacities, and enhanced durability. The increasing adoption of renewable energy systems and the growing demand for energy-efficient solutions are also contributing to the growth of the market. As the market continues to evolve, manufacturers are focusing on developing SSRs with enhanced features, such as higher load capacities, improved thermal management, and advanced protection mechanisms, to meet the evolving needs of industries.

| Report Metric | Details |

| Report Name | Panel Mount Solid State Relays (SSR) Market |

| Accounted market size in year | US$ 343 million |

| Forecasted market size in 2031 | US$ 491 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Crydom, OMRON, Carlo gavazzi, TE Connectivity, groupe celduc, Fujitsu Limited, Schneider, Siemens, Rockwell Automation, OPTO22, Xiamen Jinxinrong Electronics, JiangSu GlOD Electrical Control Technology, Clion Electric, Bright Toward, Wuxi Tianhao Electronics, Suzhou No.1 Radio Component, COSMO, Shaanxi Qunli, Wuxi Solid, Suzhou Integrated Technology, FOTEK, Wuxi KangYu Electric Element |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |