What is Global Hand-Torn Soft Cloth Abrasive Belt Market?

The Global Hand-Torn Soft Cloth Abrasive Belt Market is a specialized segment within the broader abrasive materials industry. These belts are crafted from soft cloth materials that can be easily torn by hand, making them highly versatile and user-friendly. They are primarily used for sanding and finishing applications across various industries. The unique feature of being hand-torn allows for quick adjustments and customization on the job, which is particularly beneficial in settings where precision and adaptability are crucial. These abrasive belts are available in different grit sizes, catering to a wide range of surface finishing needs, from coarse to fine. The market for these products is driven by their efficiency in providing smooth finishes and their ability to conform to different shapes and surfaces. As industries continue to demand high-quality finishes and efficient processes, the Global Hand-Torn Soft Cloth Abrasive Belt Market is expected to grow, offering innovative solutions to meet these needs. The ease of use, combined with the ability to deliver consistent results, makes these abrasive belts a preferred choice in various industrial applications.

Coarse Sand Belt, Medium Sand Belt, Fine Sand Belt in the Global Hand-Torn Soft Cloth Abrasive Belt Market:

In the Global Hand-Torn Soft Cloth Abrasive Belt Market, the products are categorized into Coarse Sand Belt, Medium Sand Belt, and Fine Sand Belt, each serving distinct purposes based on their grit size and application. Coarse Sand Belts are designed for heavy-duty tasks that require significant material removal. They are typically used in initial stages of sanding where the goal is to strip away old finishes, rust, or to shape rough surfaces. These belts are essential in industries like metalworking and woodworking, where robust and aggressive sanding is necessary to prepare surfaces for further processing. The coarse grit ensures that the material is removed quickly and efficiently, saving time and labor costs. Medium Sand Belts, on the other hand, serve as a bridge between coarse and fine sanding. They are used for intermediate sanding tasks, where the surface needs to be smoothed out after the initial rough sanding. These belts are ideal for preparing surfaces for painting or finishing, as they help in eliminating scratches left by coarse sanding. In the woodworking industry, medium sand belts are often used to smooth out wooden surfaces, ensuring that they are ready for staining or varnishing. In metalworking, they help in refining the surface after the initial shaping, making it ready for finer sanding or polishing. Fine Sand Belts are used for the final stages of sanding, where the goal is to achieve a smooth and polished finish. These belts have a high grit number, which means they remove very little material, focusing instead on refining the surface to a high degree of smoothness. Fine sand belts are crucial in applications where the appearance of the final product is of utmost importance. In the automotive industry, for instance, they are used to prepare surfaces for painting, ensuring that the paint adheres well and the finish is flawless. In the electronics industry, fine sand belts are used to polish components, ensuring that they meet the precise specifications required for high-tech applications. Each type of sand belt plays a critical role in the manufacturing and finishing processes across various industries. The choice of belt depends on the specific requirements of the task at hand, including the type of material being worked on and the desired finish. The versatility and efficiency of these belts make them indispensable tools in achieving high-quality results in industrial applications. As industries continue to evolve and demand more precise and efficient finishing solutions, the Global Hand-Torn Soft Cloth Abrasive Belt Market is poised to meet these challenges with innovative products that cater to a wide range of needs.

Metalworking Industry, Woodworking Industry, Automotive Industry, Electronics Industry, Others in the Global Hand-Torn Soft Cloth Abrasive Belt Market:

The Global Hand-Torn Soft Cloth Abrasive Belt Market finds extensive usage across several industries, each benefiting from the unique properties of these versatile tools. In the Metalworking Industry, these abrasive belts are indispensable for tasks such as deburring, surface preparation, and finishing. The ability to quickly and efficiently remove material makes them ideal for shaping and smoothing metal surfaces. Whether it's preparing a surface for welding or achieving a polished finish on a metal component, these belts provide the precision and control needed to meet the industry's high standards. In the Woodworking Industry, hand-torn soft cloth abrasive belts are used for sanding and finishing wooden surfaces. They are particularly useful in furniture making, where smooth finishes are essential for both aesthetic and functional purposes. These belts allow craftsmen to achieve a high level of detail and smoothness, enhancing the natural beauty of the wood. The ability to easily tear the belts by hand also allows for quick adjustments, making them a convenient choice for intricate woodworking tasks. The Automotive Industry relies on these abrasive belts for a variety of applications, including surface preparation and finishing. They are used to sand down body panels, remove old paint, and prepare surfaces for new coatings. The precision and control offered by these belts ensure that the surfaces are perfectly smooth, which is crucial for achieving a high-quality paint job. In addition, they are used in the finishing of interior components, ensuring that every part of the vehicle meets the industry's rigorous standards for quality and appearance. In the Electronics Industry, the demand for precision and high-quality finishes makes these abrasive belts an essential tool. They are used to polish and finish electronic components, ensuring that they meet the exacting specifications required for high-tech applications. The ability to achieve a smooth and polished finish is crucial in this industry, where even the smallest imperfections can affect the performance of electronic devices. Beyond these industries, the Global Hand-Torn Soft Cloth Abrasive Belt Market also serves a variety of other sectors, including aerospace, construction, and manufacturing. In each of these areas, the belts are valued for their versatility, efficiency, and ability to deliver consistent results. Whether it's preparing surfaces for painting, smoothing out rough edges, or achieving a polished finish, these abrasive belts provide the tools needed to meet the diverse demands of modern industry. As technology continues to advance and industries seek more efficient and precise finishing solutions, the market for these versatile tools is expected to grow, offering innovative products that cater to a wide range of applications.

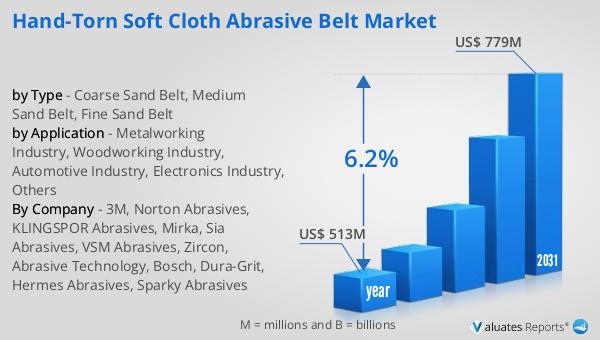

Global Hand-Torn Soft Cloth Abrasive Belt Market Outlook:

The global market for Hand-Torn Soft Cloth Abrasive Belts was valued at $513 million in 2024 and is anticipated to expand to a revised size of $779 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period. This growth trajectory underscores the increasing demand for these versatile and efficient abrasive tools across various industries. The market's expansion is driven by the need for high-quality surface finishes and the growing emphasis on efficient manufacturing processes. As industries continue to evolve and demand more precise and efficient finishing solutions, the Global Hand-Torn Soft Cloth Abrasive Belt Market is poised to meet these challenges with innovative products that cater to a wide range of needs. The ability of these belts to deliver consistent results, combined with their ease of use and adaptability, makes them a preferred choice in industrial applications. As a result, the market is expected to continue its upward trend, offering new opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Hand-Torn Soft Cloth Abrasive Belt Market |

| Accounted market size in year | US$ 513 million |

| Forecasted market size in 2031 | US$ 779 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, Norton Abrasives, KLINGSPOR Abrasives, Mirka, Sia Abrasives, VSM Abrasives, Zircon, Abrasive Technology, Bosch, Dura-Grit, Hermes Abrasives, Sparky Abrasives |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |