What is Global Automatic Splicing Machine Market?

The Global Automatic Splicing Machine Market refers to the industry focused on the production and distribution of machines designed to join two ends of a material, such as film, tape, or paper, without stopping the production process. These machines are essential in industries where continuous production is crucial, as they help minimize downtime and increase efficiency. Automatic splicing machines are widely used in various sectors, including packaging, printing, textiles, and electronics, where they ensure seamless transitions between material rolls. The market for these machines is driven by the growing demand for automation in manufacturing processes, as companies seek to improve productivity and reduce labor costs. Technological advancements have led to the development of more sophisticated splicing machines that offer higher precision and reliability. Additionally, the increasing focus on sustainability and waste reduction has prompted manufacturers to adopt automatic splicing machines to minimize material wastage. As industries continue to evolve and embrace automation, the demand for automatic splicing machines is expected to grow, making it a vital component of modern manufacturing processes.

Code Scanning Gun Reading Code, Receiver Arm Camera Reading Code in the Global Automatic Splicing Machine Market:

In the realm of the Global Automatic Splicing Machine Market, technologies like Code Scanning Gun Reading Code and Receiver Arm Camera Reading Code play pivotal roles. These technologies are integral to the functioning of automatic splicing machines, enhancing their efficiency and accuracy. Code Scanning Gun Reading Code involves the use of handheld or mounted devices that scan barcodes or QR codes on materials being processed. This technology ensures that the correct materials are being spliced and that the process is aligned with production requirements. It helps in tracking and managing inventory, reducing errors, and ensuring that the splicing process is seamless. On the other hand, Receiver Arm Camera Reading Code involves the use of cameras mounted on the splicing machine's receiver arm. These cameras capture images of the material being processed and use image recognition software to read codes printed on the material. This technology provides an additional layer of verification, ensuring that the right materials are being used and that the splicing process is proceeding correctly. The integration of these technologies into automatic splicing machines has revolutionized the way industries manage their production processes. They offer real-time data and analytics, allowing manufacturers to monitor and optimize their operations. This level of automation and precision is particularly beneficial in industries where high volumes of materials are processed, such as packaging and textiles. By reducing the likelihood of errors and ensuring that the correct materials are used, these technologies help manufacturers maintain high standards of quality and efficiency. Furthermore, the use of Code Scanning Gun Reading Code and Receiver Arm Camera Reading Code in automatic splicing machines aligns with the broader trend of digital transformation in manufacturing. As industries increasingly adopt digital technologies to enhance their operations, the demand for advanced splicing machines equipped with these capabilities is expected to rise. These technologies not only improve the functionality of splicing machines but also contribute to the overall efficiency and competitiveness of manufacturing processes. In conclusion, the integration of Code Scanning Gun Reading Code and Receiver Arm Camera Reading Code into automatic splicing machines represents a significant advancement in the Global Automatic Splicing Machine Market. These technologies enhance the accuracy, efficiency, and reliability of splicing processes, making them indispensable tools for modern manufacturing. As industries continue to evolve and embrace digital transformation, the demand for splicing machines equipped with these advanced capabilities is likely to grow, driving further innovation and development in the market.

Consumer Electronics, Automotive Electronics, Aerospace, Others in the Global Automatic Splicing Machine Market:

The Global Automatic Splicing Machine Market finds extensive applications across various industries, including consumer electronics, automotive electronics, aerospace, and others. In the consumer electronics sector, automatic splicing machines are used to join materials such as films and tapes that are essential in the production of electronic components. These machines ensure that the production process is continuous and efficient, reducing downtime and increasing productivity. The precision and reliability offered by automatic splicing machines are crucial in maintaining the high standards of quality required in the consumer electronics industry. In the automotive electronics sector, automatic splicing machines play a vital role in the production of electronic components used in vehicles. These machines help in joining materials such as wires and cables, ensuring that the production process is seamless and efficient. The automotive industry demands high levels of precision and reliability, and automatic splicing machines help manufacturers meet these requirements. In the aerospace industry, automatic splicing machines are used to join materials such as films and tapes that are used in the production of aircraft components. The aerospace industry requires materials that are lightweight yet strong, and automatic splicing machines help in achieving this balance by ensuring that the materials are joined accurately and efficiently. The use of automatic splicing machines in the aerospace industry helps manufacturers maintain high standards of quality and safety. In addition to these industries, automatic splicing machines are also used in other sectors such as textiles, packaging, and printing. In the textiles industry, these machines are used to join fabrics and other materials, ensuring that the production process is continuous and efficient. In the packaging industry, automatic splicing machines help in joining materials such as films and tapes, ensuring that the packaging process is seamless and efficient. In the printing industry, these machines are used to join paper and other materials, ensuring that the printing process is continuous and efficient. Overall, the Global Automatic Splicing Machine Market plays a crucial role in enhancing the efficiency and productivity of various industries. The demand for these machines is driven by the need for automation and precision in manufacturing processes, as well as the increasing focus on sustainability and waste reduction. As industries continue to evolve and embrace automation, the demand for automatic splicing machines is expected to grow, making them an essential component of modern manufacturing processes.

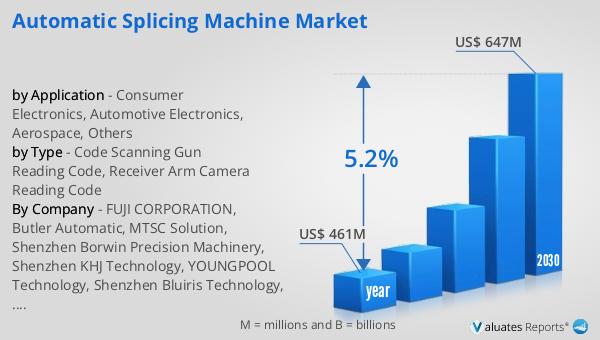

Global Automatic Splicing Machine Market Outlook:

In 2023, the global market for Automatic Splicing Machines was valued at approximately $461 million. This market is anticipated to expand significantly, reaching an estimated value of $647 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. The increasing demand for automation in manufacturing processes is a key driver of this market growth. As industries strive to enhance productivity and reduce operational costs, the adoption of automatic splicing machines is becoming more prevalent. These machines offer numerous advantages, including improved efficiency, reduced downtime, and enhanced precision, making them indispensable in various sectors such as packaging, textiles, and electronics. Additionally, technological advancements in splicing machines, such as the integration of digital technologies and advanced control systems, are further propelling market growth. These innovations enable manufacturers to optimize their production processes, reduce material wastage, and maintain high standards of quality. Furthermore, the growing emphasis on sustainability and waste reduction is encouraging industries to adopt automatic splicing machines, as they help minimize material wastage and improve overall efficiency. As a result, the global market for automatic splicing machines is poised for substantial growth in the coming years, driven by the increasing demand for automation and the continuous evolution of manufacturing processes.

| Report Metric | Details |

| Report Name | Automatic Splicing Machine Market |

| Accounted market size in year | US$ 461 million |

| Forecasted market size in 2030 | US$ 647 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | FUJI CORPORATION, Butler Automatic, MTSC Solution, Shenzhen Borwin Precision Machinery, Shenzhen KHJ Technology, YOUNGPOOL Technology, Shenzhen Bluiris Technology, Jinyao Intelligent Precision (Shenzhen), Jiedeng Intelligence, EVER-WIN Technology, Suzhou Precision Manufacture for Life, Shenzhen Zhiheng Electromechanical, Fortune Tell |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |