What is Global High-Throughput Microbioreactor Market?

The Global High-Throughput Microbioreactor Market is a rapidly evolving sector that focuses on the development and utilization of advanced microbioreactor systems. These systems are designed to facilitate high-throughput screening and optimization of microbial cultures, which are essential in various fields such as biotechnology, pharmaceuticals, and food and beverages. High-throughput microbioreactors are small-scale bioreactors that allow researchers to conduct multiple experiments simultaneously, significantly speeding up the research and development process. They are equipped with advanced sensors and control systems that enable precise monitoring and control of environmental conditions such as temperature, pH, and dissolved oxygen levels. This precision is crucial for optimizing microbial growth and product formation. The market for these microbioreactors is driven by the increasing demand for efficient and cost-effective solutions in bioprocessing and the growing emphasis on sustainable and environmentally friendly production methods. As industries continue to seek ways to enhance productivity and reduce costs, the adoption of high-throughput microbioreactors is expected to rise, making this market a key area of interest for researchers and companies alike.

Batch, Fed-Batch, Continuous in the Global High-Throughput Microbioreactor Market:

In the Global High-Throughput Microbioreactor Market, different operational modes such as Batch, Fed-Batch, and Continuous are employed to optimize microbial processes. Each mode offers unique advantages and is chosen based on the specific requirements of the process being studied. Batch processing is the simplest and most traditional method, where all the nutrients are added at the beginning of the process, and the culture is allowed to grow until the nutrients are exhausted. This method is straightforward and easy to control, making it suitable for processes where the end product is not sensitive to changes in nutrient concentration. However, it may not be the most efficient method for processes that require constant nutrient supply or where product inhibition is a concern.

Biotechnology Research and Development, Pharmaceuticals, Food and Beverages, Others in the Global High-Throughput Microbioreactor Market:

Fed-Batch processing, on the other hand, involves the gradual addition of nutrients during the cultivation process. This method allows for better control over the growth environment and can lead to higher product yields. By controlling the feed rate, researchers can optimize the growth conditions and minimize the accumulation of inhibitory by-products. Fed-Batch is particularly useful in processes where the product formation is growth-associated, and it is widely used in the production of pharmaceuticals and biochemicals. The flexibility of this method makes it a popular choice in the high-throughput microbioreactor market, as it allows for the fine-tuning of process parameters to achieve optimal results.

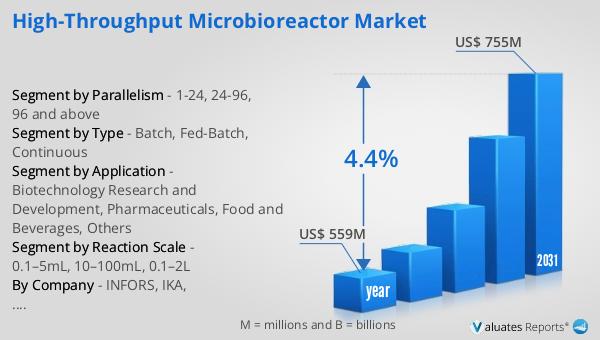

Global High-Throughput Microbioreactor Market Outlook:

Continuous processing is another approach used in the Global High-Throughput Microbioreactor Market, where fresh nutrients are continuously supplied, and culture broth is continuously removed. This method maintains a steady state of operation, allowing for constant product formation and reducing downtime between batches. Continuous processing is highly efficient and can lead to significant cost savings, especially in large-scale operations. It is ideal for processes where the product is not growth-associated and where maintaining a constant environment is crucial for product quality. However, continuous processing requires sophisticated control systems and is more complex to manage compared to batch and fed-batch methods. Despite these challenges, continuous processing is gaining popularity in the market due to its potential for high productivity and efficiency.

| Report Metric | Details |

| Report Name | High-Throughput Microbioreactor Market |

| Accounted market size in year | US$ 559 million |

| Forecasted market size in 2031 | US$ 755 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Parallelism |

|

| Segment by Reaction Scale |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | INFORS, IKA, Eppendorf, Thermo Fisher Scientific, Memmert, Shanghai Zhichu Instrumen, Being, Shiping, Minquan Instruments, Ruizhi Biology, Changzhou Jintan Jingda Instrument Manufacturing, Labfirst Scientific |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |