What is Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market?

The Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market is a specialized segment within the electronics manufacturing industry that focuses on the precise placement of solder balls onto semiconductor packages. These packages, such as Ball Grid Array (BGA), Chip Scale Package (CSP), and Flip Chip Ball Grid Array (FCBGA), are essential components in modern electronic devices, providing the necessary connections between the chip and the circuit board. The automatic solder ball mounter machines are designed to enhance the efficiency and accuracy of this process, ensuring that each solder ball is placed correctly to maintain the integrity and functionality of the electronic device. This market is driven by the increasing demand for miniaturized and high-performance electronic devices, which require advanced packaging solutions. As technology continues to evolve, the need for more sophisticated and reliable solder ball mounting solutions is expected to grow, making this market a critical component of the global electronics manufacturing landscape. The precision and automation offered by these machines not only improve production efficiency but also reduce the likelihood of defects, thereby enhancing the overall quality of electronic products.

Fully Automatic, Semi-Automatic in the Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market:

In the Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market, machines are categorized into two main types: fully automatic and semi-automatic. Fully automatic solder ball mounters are designed to operate with minimal human intervention, offering high-speed and high-precision placement of solder balls. These machines are equipped with advanced sensors and software that allow them to accurately position solder balls on semiconductor packages, ensuring consistent quality and reducing the risk of errors. The automation of this process not only increases production efficiency but also allows manufacturers to meet the growing demand for complex and miniaturized electronic components. Fully automatic machines are particularly beneficial in large-scale production environments where speed and precision are paramount. They are capable of handling a wide range of package sizes and types, making them versatile tools in the electronics manufacturing industry. On the other hand, semi-automatic solder ball mounters require some level of human intervention, typically in the setup and monitoring stages. These machines offer a balance between automation and manual control, allowing operators to make adjustments as needed to accommodate different package types and production requirements. While they may not match the speed and precision of fully automatic machines, semi-automatic mounters provide flexibility and are often more cost-effective for smaller production runs or specialized applications. They are ideal for manufacturers who need to maintain a degree of manual oversight while still benefiting from the efficiencies of automation. Both fully automatic and semi-automatic solder ball mounters play a crucial role in the electronics manufacturing process, each offering unique advantages depending on the specific needs of the production environment. As the demand for advanced electronic devices continues to rise, the importance of these machines in ensuring the quality and reliability of semiconductor packages cannot be overstated. Manufacturers must carefully consider their production requirements and choose the appropriate type of solder ball mounter to optimize their operations and meet market demands.

Substrate, Chip, Wafer in the Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market:

The Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market finds significant applications in the areas of substrates, chips, and wafers, each playing a crucial role in the electronics manufacturing process. Substrates serve as the foundational layer for semiconductor devices, providing the necessary support and electrical connections for the chip. In this context, automatic solder ball mounters are used to accurately place solder balls on the substrate, ensuring a reliable connection between the chip and the circuit board. The precision offered by these machines is essential in maintaining the integrity of the substrate and preventing defects that could compromise the performance of the electronic device. In chip applications, solder ball mounters are used to attach solder balls directly to the semiconductor chip, facilitating the connection to the substrate or circuit board. This process is critical in the production of advanced packaging solutions such as BGA and CSP, where the miniaturization of components requires precise and reliable solder ball placement. The use of automatic solder ball mounters in chip applications ensures that each solder ball is positioned accurately, reducing the risk of electrical failures and enhancing the overall performance of the device. In wafer applications, solder ball mounters are employed in the final stages of semiconductor manufacturing, where solder balls are placed on the wafer to create the necessary connections for packaging. This process is particularly important in the production of flip-chip packages, where the chip is mounted directly onto the circuit board. The use of automatic solder ball mounters in wafer applications ensures that each solder ball is placed with the utmost precision, maintaining the integrity of the wafer and ensuring the reliability of the final product. The versatility and precision of automatic solder ball mounters make them indispensable tools in the electronics manufacturing industry, enabling the production of high-performance and reliable electronic devices.

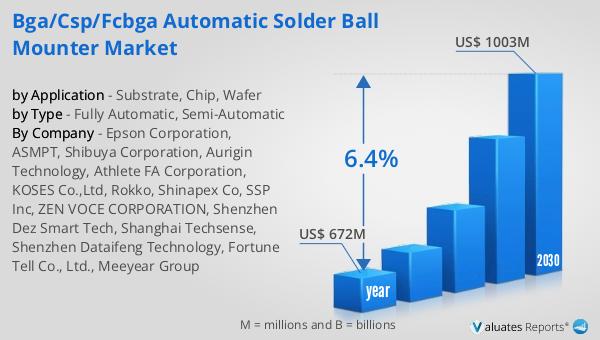

Global BGA/CSP/FCBGA Automatic Solder Ball Mounter Market Outlook:

The global market for BGA/CSP/FCBGA Automatic Solder Ball Mounters was valued at approximately $672 million in 2023. This market is anticipated to expand significantly, reaching an estimated size of $1,003 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 6.4% over the forecast period. This upward trend is indicative of the increasing demand for advanced electronic devices that require sophisticated packaging solutions. The precision and efficiency offered by automatic solder ball mounters are crucial in meeting the needs of modern electronics manufacturing, where miniaturization and high performance are key drivers. As technology continues to advance, the demand for reliable and efficient solder ball mounting solutions is expected to rise, further fueling the growth of this market. The projected growth in the market underscores the importance of these machines in the electronics manufacturing industry, highlighting their role in ensuring the quality and reliability of semiconductor packages. Manufacturers are likely to invest in advanced solder ball mounter technologies to enhance their production capabilities and meet the evolving demands of the market. This growth also reflects the broader trends in the electronics industry, where innovation and technological advancements continue to drive the need for more sophisticated manufacturing solutions.

| Report Metric | Details |

| Report Name | BGA/CSP/FCBGA Automatic Solder Ball Mounter Market |

| Accounted market size in year | US$ 672 million |

| Forecasted market size in 2030 | US$ 1003 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Epson Corporation, ASMPT, Shibuya Corporation, Aurigin Technology, Athlete FA Corporation, KOSES Co.,Ltd, Rokko, Shinapex Co, SSP Inc, ZEN VOCE CORPORATION, Shenzhen Dez Smart Tech, Shanghai Techsense, Shenzhen Dataifeng Technology, Fortune Tell Co., Ltd., Meeyear Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |