What is Global Fully Automatic BGA Solder Ball Mounter Market?

The Global Fully Automatic BGA Solder Ball Mounter Market is a specialized segment within the electronics manufacturing industry, focusing on the automated placement of solder balls onto Ball Grid Array (BGA) packages. These machines are crucial in the assembly of electronic components, ensuring precision and efficiency in the soldering process. BGA packages are widely used in various electronic devices, including smartphones, computers, and other consumer electronics, due to their ability to provide high-density connections. The fully automatic BGA solder ball mounters are designed to handle the intricate task of placing tiny solder balls onto the BGA substrates with high accuracy and speed. This automation reduces the risk of human error, enhances production efficiency, and ensures consistent quality in the final products. The market for these machines is driven by the increasing demand for miniaturized electronic devices and the need for advanced packaging solutions that can support higher performance and functionality. As technology continues to evolve, the demand for fully automatic BGA solder ball mounters is expected to grow, driven by advancements in semiconductor manufacturing and the ongoing trend towards smaller, more powerful electronic devices.

Ball Planting Accuracy ±0.015mm, Ball Planting Accuracy ±0.025mm, Ball Planting Accuracy ±0.030mm in the Global Fully Automatic BGA Solder Ball Mounter Market:

Ball planting accuracy is a critical parameter in the Global Fully Automatic BGA Solder Ball Mounter Market, as it directly impacts the performance and reliability of electronic components. The accuracy levels, such as ±0.015mm, ±0.025mm, and ±0.030mm, refer to the precision with which solder balls are placed on the BGA substrates. A higher accuracy level, such as ±0.015mm, indicates a more precise placement, which is essential for high-performance applications where even the slightest deviation can lead to significant issues. This level of precision is particularly important in advanced semiconductor applications, where the components are densely packed, and the margin for error is minimal. On the other hand, ±0.025mm and ±0.030mm accuracies are suitable for applications where the requirements are less stringent, but still demand a high level of precision to ensure the reliability and functionality of the electronic devices. The choice of accuracy level depends on the specific requirements of the application, the complexity of the BGA package, and the desired performance characteristics. Manufacturers in the Global Fully Automatic BGA Solder Ball Mounter Market continuously strive to improve the accuracy of their machines to meet the evolving demands of the electronics industry. This involves investing in advanced technologies, such as vision systems and precision control mechanisms, to enhance the placement accuracy and ensure consistent quality. The ability to achieve high accuracy in ball planting is a key differentiator for manufacturers, as it directly impacts the performance and reliability of the final products. As the demand for more compact and powerful electronic devices continues to grow, the need for high-precision BGA solder ball mounters is expected to increase, driving further advancements in accuracy and technology. The market is also influenced by the increasing complexity of electronic components, which requires more precise and reliable soldering solutions. As a result, manufacturers are focusing on developing machines that can handle a wide range of BGA packages with varying levels of complexity and accuracy requirements. This includes the ability to adapt to different substrate materials, ball sizes, and placement patterns, ensuring versatility and flexibility in the manufacturing process. The Global Fully Automatic BGA Solder Ball Mounter Market is characterized by a high level of competition, with manufacturers constantly seeking to differentiate themselves through innovation and technological advancements. This has led to the development of machines with enhanced features, such as automated calibration, real-time monitoring, and advanced error detection capabilities, to improve accuracy and efficiency. The focus on accuracy is also driven by the increasing demand for high-reliability applications, such as automotive and aerospace, where the performance and safety of electronic components are critical. In these industries, even a minor deviation in ball placement can lead to significant issues, making high accuracy a top priority. As a result, manufacturers are investing in research and development to push the boundaries of accuracy and deliver machines that can meet the stringent requirements of these applications. The Global Fully Automatic BGA Solder Ball Mounter Market is poised for growth as manufacturers continue to innovate and improve the accuracy of their machines to meet the evolving demands of the electronics industry. The focus on accuracy is not only about meeting current requirements but also about anticipating future needs as electronic devices become more complex and demanding. This requires a proactive approach to innovation, with manufacturers constantly exploring new technologies and techniques to enhance accuracy and performance. The market is also influenced by the increasing adoption of Industry 4.0 technologies, which are driving the demand for more advanced and automated manufacturing solutions. This includes the integration of artificial intelligence, machine learning, and data analytics to improve accuracy, efficiency, and productivity in the manufacturing process. As the Global Fully Automatic BGA Solder Ball Mounter Market continues to evolve, accuracy will remain a key focus, driving further advancements and innovations in the industry.

Substrate, Chip, Wafer in the Global Fully Automatic BGA Solder Ball Mounter Market:

The Global Fully Automatic BGA Solder Ball Mounter Market plays a crucial role in various areas of electronics manufacturing, including substrates, chips, and wafers. In the context of substrates, these machines are used to place solder balls onto the BGA substrates, which serve as the foundation for electronic components. The precision and accuracy of the solder ball placement are critical to ensuring the reliability and performance of the final product. Substrates are often made of materials such as ceramic or organic compounds, which require careful handling and precise soldering to avoid damage and ensure optimal performance. The fully automatic BGA solder ball mounters are designed to handle these materials with care, providing consistent and reliable results. In the area of chips, the Global Fully Automatic BGA Solder Ball Mounter Market is essential for the assembly of semiconductor devices. Chips are the core components of electronic devices, and their performance is directly influenced by the quality of the soldering process. The precision and accuracy of the solder ball placement are critical to ensuring the electrical connectivity and functionality of the chips. Fully automatic BGA solder ball mounters provide the necessary precision and speed to handle the complex and delicate nature of chip assembly, reducing the risk of defects and improving overall yield. The use of these machines in chip manufacturing is driven by the increasing demand for smaller, more powerful, and energy-efficient devices, which require advanced packaging solutions to support their performance and functionality. In the context of wafers, the Global Fully Automatic BGA Solder Ball Mounter Market is used to place solder balls onto the wafer-level packages, which are used in advanced semiconductor applications. Wafers are thin slices of semiconductor material, such as silicon, that serve as the substrate for integrated circuits. The precision and accuracy of the solder ball placement are critical to ensuring the performance and reliability of the wafer-level packages. Fully automatic BGA solder ball mounters provide the necessary precision and speed to handle the complex and delicate nature of wafer-level packaging, reducing the risk of defects and improving overall yield. The use of these machines in wafer manufacturing is driven by the increasing demand for advanced semiconductor applications, such as 5G, IoT, and AI, which require high-performance and reliable packaging solutions. The Global Fully Automatic BGA Solder Ball Mounter Market is characterized by a high level of competition, with manufacturers constantly seeking to differentiate themselves through innovation and technological advancements. This has led to the development of machines with enhanced features, such as automated calibration, real-time monitoring, and advanced error detection capabilities, to improve accuracy and efficiency. The focus on accuracy is also driven by the increasing demand for high-reliability applications, such as automotive and aerospace, where the performance and safety of electronic components are critical. In these industries, even a minor deviation in ball placement can lead to significant issues, making high accuracy a top priority. As a result, manufacturers are investing in research and development to push the boundaries of accuracy and deliver machines that can meet the stringent requirements of these applications. The Global Fully Automatic BGA Solder Ball Mounter Market is poised for growth as manufacturers continue to innovate and improve the accuracy of their machines to meet the evolving demands of the electronics industry. The focus on accuracy is not only about meeting current requirements but also about anticipating future needs as electronic devices become more complex and demanding. This requires a proactive approach to innovation, with manufacturers constantly exploring new technologies and techniques to enhance accuracy and performance. The market is also influenced by the increasing adoption of Industry 4.0 technologies, which are driving the demand for more advanced and automated manufacturing solutions. This includes the integration of artificial intelligence, machine learning, and data analytics to improve accuracy, efficiency, and productivity in the manufacturing process. As the Global Fully Automatic BGA Solder Ball Mounter Market continues to evolve, accuracy will remain a key focus, driving further advancements and innovations in the industry.

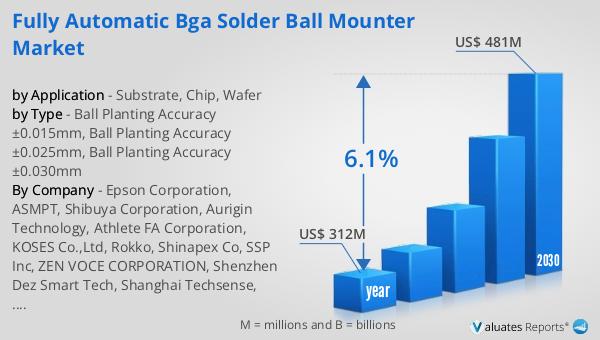

Global Fully Automatic BGA Solder Ball Mounter Market Outlook:

In 2023, the worldwide market for Fully Automatic BGA Solder Ball Mounters was valued at approximately $312 million. This market is anticipated to expand significantly, reaching an estimated size of $481 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 6.1% over the forecast period. The increasing demand for miniaturized and high-performance electronic devices is a major driver of this market growth. As technology advances, there is a growing need for more efficient and precise manufacturing solutions, which fully automatic BGA solder ball mounters provide. These machines are essential in the electronics manufacturing industry, offering high precision and efficiency in the soldering process, which is crucial for the assembly of electronic components. The market's growth is also fueled by the ongoing trend towards automation and the adoption of Industry 4.0 technologies, which are driving the demand for more advanced and automated manufacturing solutions. As a result, manufacturers are investing in research and development to enhance the capabilities of their machines and meet the evolving demands of the electronics industry. The Global Fully Automatic BGA Solder Ball Mounter Market is expected to continue its growth trajectory, driven by the increasing demand for advanced packaging solutions and the ongoing trend towards smaller, more powerful electronic devices.

| Report Metric | Details |

| Report Name | Fully Automatic BGA Solder Ball Mounter Market |

| Accounted market size in year | US$ 312 million |

| Forecasted market size in 2030 | US$ 481 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Epson Corporation, ASMPT, Shibuya Corporation, Aurigin Technology, Athlete FA Corporation, KOSES Co.,Ltd, Rokko, Shinapex Co, SSP Inc, ZEN VOCE CORPORATION, Shenzhen Dez Smart Tech, Shanghai Techsense, Shenzhen Dataifeng Technology, Fortune Tell Co., Ltd., Meeyear Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |