What is Global Automotive Locating Pins Market?

The Global Automotive Locating Pins Market is a specialized segment within the automotive industry that focuses on the production and distribution of locating pins used in vehicle assembly processes. These pins are crucial components in the manufacturing of automobiles, as they ensure precise alignment and positioning of various parts during assembly. By providing accurate alignment, locating pins help in maintaining the structural integrity and performance of vehicles. The market for these pins is driven by the increasing demand for automobiles worldwide, as well as the need for enhanced manufacturing precision and efficiency. Automotive locating pins are typically made from durable materials such as alloy steel, stainless steel, and carbon steel, which contribute to their strength and longevity. The market is characterized by a variety of pin types and sizes, catering to different vehicle models and manufacturing requirements. As the automotive industry continues to evolve with advancements in technology and production techniques, the demand for high-quality locating pins is expected to grow, supporting the overall expansion of the Global Automotive Locating Pins Market.

Press-in Type, Removable Type in the Global Automotive Locating Pins Market:

In the Global Automotive Locating Pins Market, two primary types of pins are widely used: Press-in Type and Removable Type. Each type serves a distinct purpose and offers unique advantages in the automotive assembly process. Press-in Type locating pins are designed to be permanently fixed into place. They are typically used in applications where a secure and stable alignment is crucial, and there is no need for frequent removal or adjustment. These pins are inserted into pre-drilled holes and are held in place by friction, ensuring a tight fit. The main advantage of Press-in Type pins is their ability to provide a consistent and reliable alignment, which is essential for maintaining the quality and performance of the assembled vehicle. They are often made from robust materials like alloy steel or stainless steel, which offer excellent resistance to wear and corrosion, ensuring long-term durability. On the other hand, Removable Type locating pins are designed for applications where flexibility and ease of removal are important. These pins can be easily inserted and removed as needed, making them ideal for situations where components need to be frequently adjusted or replaced. Removable Type pins are often used in assembly processes that require regular maintenance or reconfiguration. They are typically equipped with features such as threaded ends or quick-release mechanisms, which facilitate easy installation and removal. The choice between Press-in Type and Removable Type locating pins depends on various factors, including the specific requirements of the assembly process, the materials being used, and the desired level of precision and flexibility. In some cases, a combination of both types may be used to achieve the optimal balance of stability and adaptability. As the automotive industry continues to advance, manufacturers are constantly seeking ways to improve the efficiency and precision of their assembly processes. This has led to the development of innovative locating pin designs and materials, aimed at enhancing performance and reducing production costs. For instance, some manufacturers are exploring the use of advanced materials such as composite materials or coatings that offer superior wear resistance and reduced friction. Additionally, the integration of smart technologies, such as sensors or RFID tags, into locating pins is being explored to enable real-time monitoring and data collection during the assembly process. This can provide valuable insights into the performance and condition of the pins, allowing for proactive maintenance and optimization of the assembly line. Overall, the choice between Press-in Type and Removable Type locating pins is a critical decision that can significantly impact the efficiency and quality of the automotive assembly process. By understanding the unique characteristics and benefits of each type, manufacturers can make informed decisions that align with their specific production goals and requirements. As the Global Automotive Locating Pins Market continues to evolve, the demand for high-quality, reliable, and versatile locating pins is expected to grow, driving further innovation and development in this essential segment of the automotive industry.

Passenger Vehicles, Commercial Vehicles in the Global Automotive Locating Pins Market:

The usage of Global Automotive Locating Pins Market in passenger vehicles and commercial vehicles is integral to the assembly and manufacturing processes of these vehicles. In passenger vehicles, locating pins play a crucial role in ensuring the precise alignment and positioning of various components, such as body panels, doors, and engine parts. This precision is essential for maintaining the aesthetic appeal, structural integrity, and overall performance of the vehicle. Locating pins help in reducing assembly errors and improving the fit and finish of the vehicle, which is critical for meeting consumer expectations and industry standards. In commercial vehicles, the role of locating pins is equally important, as these vehicles often require robust and durable construction to withstand heavy usage and demanding operating conditions. Locating pins are used in the assembly of chassis, suspension systems, and other critical components, ensuring that they are accurately aligned and securely fastened. This is vital for maintaining the safety, reliability, and longevity of commercial vehicles, which are often subjected to rigorous use in various industries such as transportation, logistics, and construction. The use of locating pins in both passenger and commercial vehicles also contributes to the efficiency and productivity of the manufacturing process. By providing a reliable and consistent method for aligning and positioning components, locating pins help in reducing assembly time and minimizing the risk of errors or defects. This, in turn, leads to cost savings and improved production efficiency, which are crucial for manufacturers operating in a highly competitive automotive market. Additionally, the use of locating pins supports the implementation of advanced manufacturing techniques, such as automation and robotics, which rely on precise alignment and positioning to function effectively. As the automotive industry continues to evolve, the demand for high-quality locating pins is expected to grow, driven by the increasing complexity and sophistication of modern vehicles. Manufacturers are constantly seeking ways to enhance the performance and efficiency of their assembly processes, and locating pins play a vital role in achieving these goals. By ensuring the accurate alignment and positioning of components, locating pins contribute to the overall quality and performance of both passenger and commercial vehicles, supporting the continued growth and development of the Global Automotive Locating Pins Market.

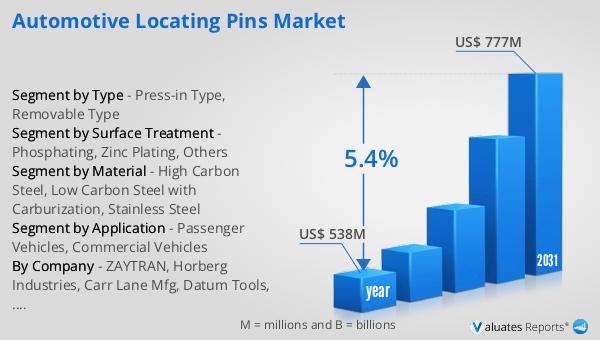

Global Automotive Locating Pins Market Outlook:

The worldwide market for Automotive Locating Pins was estimated to be worth $538 million in 2024, and it is anticipated to expand to a revised valuation of $777 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. The primary raw materials used in the production of these pins include alloy steel, stainless steel, and carbon steel bars, which together account for about 72% of the total product costs. These materials are chosen for their strength, durability, and resistance to wear and corrosion, which are essential qualities for components used in the demanding environment of automotive manufacturing. The reliance on these high-quality materials underscores the importance of material selection in the production of locating pins, as it directly impacts the performance and longevity of the final product. As the market continues to grow, manufacturers are likely to explore new materials and production techniques to enhance the quality and cost-effectiveness of their products. This focus on innovation and material optimization is expected to drive further advancements in the Global Automotive Locating Pins Market, supporting its continued expansion and development.

| Report Metric | Details |

| Report Name | Automotive Locating Pins Market |

| Accounted market size in year | US$ 538 million |

| Forecasted market size in 2031 | US$ 777 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Material |

|

| Segment by Surface Treatment |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ZAYTRAN, Horberg Industries, Carr Lane Mfg, Datum Tools, Fastco Industries Inc., Hartford Technologies, NMB Technologies, FANLIAN, Champ-j, System 22, Inc., Forster Tool, ADEWO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |