What is Global Seamless Holographic Embossing Machine Market?

The Global Seamless Holographic Embossing Machine Market is an intriguing segment of the manufacturing industry that focuses on the production of machines capable of creating seamless holographic patterns on various materials. These machines are pivotal in industries where visual appeal and security are paramount. Seamless holographic embossing machines are used to produce holograms that are continuous and without visible seams, enhancing the aesthetic and functional value of products. This technology is particularly significant in packaging, where it not only adds a layer of sophistication but also serves as a deterrent against counterfeiting. The market for these machines is driven by the increasing demand for innovative packaging solutions and the need for enhanced security features in products. As industries continue to seek ways to differentiate their products and protect their brands, the demand for seamless holographic embossing machines is expected to grow. These machines are not only about aesthetics but also about providing a practical solution to the ever-present challenge of counterfeiting, making them an essential tool in modern manufacturing.

Hot Stamping Embossing, Cold Stamping Embossing, Digital Holographic Embossing in the Global Seamless Holographic Embossing Machine Market:

Hot stamping embossing, cold stamping embossing, and digital holographic embossing are three distinct techniques within the Global Seamless Holographic Embossing Machine Market, each offering unique benefits and applications. Hot stamping embossing involves the use of heat and pressure to transfer a holographic image onto a substrate. This method is widely used due to its ability to produce high-quality, durable images that are resistant to wear and tear. The process involves a heated die that presses a holographic foil onto the material, creating a permanent bond. This technique is particularly popular in the packaging industry, where it is used to create eye-catching designs that enhance product appeal and provide a level of security against counterfeiting. Cold stamping embossing, on the other hand, does not require heat. Instead, it relies on pressure and a special adhesive to transfer the holographic image onto the substrate. This method is advantageous for materials that are sensitive to heat, such as certain plastics and papers. Cold stamping is often used in applications where speed and efficiency are critical, as it allows for faster production times compared to hot stamping. Digital holographic embossing is a more recent innovation that leverages digital technology to create holographic images. This method offers unparalleled flexibility and precision, allowing for the creation of complex and intricate designs that would be difficult to achieve with traditional methods. Digital holographic embossing is particularly useful in short-run productions and custom applications, where the ability to quickly and easily change designs is a significant advantage. Each of these embossing techniques plays a crucial role in the Global Seamless Holographic Embossing Machine Market, catering to different needs and preferences across various industries. As technology continues to advance, these methods are likely to evolve, offering even more possibilities for innovation and creativity in product design and security.

Anti-counterfeiting Packaging, Printing, Others in the Global Seamless Holographic Embossing Machine Market:

The usage of Global Seamless Holographic Embossing Machines spans several critical areas, including anti-counterfeiting, packaging, printing, and other applications. In the realm of anti-counterfeiting, these machines are indispensable. Counterfeiting is a significant issue across many industries, from pharmaceuticals to luxury goods, and seamless holographic embossing provides a robust solution. By embedding intricate holographic patterns into products or packaging, manufacturers can create a unique identifier that is extremely difficult to replicate. This not only helps in protecting the brand but also ensures consumer safety by preventing the distribution of counterfeit products. In packaging, seamless holographic embossing machines are used to enhance the visual appeal of products. The ability to create continuous, seamless holographic designs allows brands to stand out on the shelves, attracting consumers' attention and conveying a sense of quality and innovation. This is particularly important in competitive markets where packaging can be a key differentiator. Additionally, the use of holography in packaging can also serve a functional purpose, such as indicating tampering or ensuring product authenticity. In the printing industry, seamless holographic embossing machines are used to produce high-quality, visually striking materials. From book covers to promotional materials, the addition of holographic elements can elevate the perceived value of printed products. This is especially relevant in sectors where first impressions are crucial, such as marketing and advertising. Beyond these primary applications, seamless holographic embossing machines are also used in various other fields. For instance, in the automotive industry, they can be used to create decorative elements on vehicle interiors. In electronics, they can be used to enhance the appearance of devices or to provide security features on components. The versatility of these machines makes them a valuable asset across multiple sectors, driving innovation and providing solutions to complex challenges.

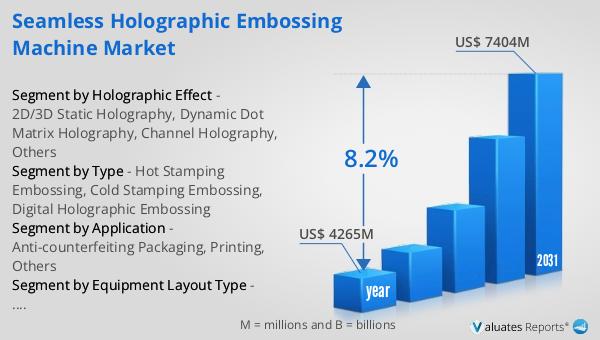

Global Seamless Holographic Embossing Machine Market Outlook:

The outlook for the Global Seamless Holographic Embossing Machine Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 4,265 million. By 2031, it is expected to expand to a revised size of around US$ 7,404 million, reflecting a compound annual growth rate (CAGR) of 8.2% during the forecast period. This growth is indicative of the increasing demand for advanced embossing solutions across various industries. The rise in market value can be attributed to several factors, including the growing need for anti-counterfeiting measures, the demand for innovative packaging solutions, and advancements in embossing technology. As industries continue to evolve and face new challenges, the role of seamless holographic embossing machines becomes even more critical. These machines not only provide aesthetic enhancements but also offer practical solutions to issues such as counterfeiting and brand differentiation. The projected growth of the market underscores the importance of these machines in modern manufacturing and their potential to drive innovation and efficiency across multiple sectors. As businesses seek to enhance their products and protect their brands, the demand for seamless holographic embossing machines is likely to continue its upward trajectory.

| Report Metric | Details |

| Report Name | Seamless Holographic Embossing Machine Market |

| Accounted market size in year | US$ 4265 million |

| Forecasted market size in 2031 | US$ 7404 million |

| CAGR | 8.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Holographic Effect |

|

| Segment by Equipment Layout Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kingsun Machinery, YIMING, Witymachinery, KELEI, Sunny Machinery Factory, Kompass, Wenzhou Wenxin Printing Technology Co.,Ltd., CBADEN, SHUANGLONG, Zomagtc Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |