What is Global Fully Automatic First Article Detector Market?

The Global Fully Automatic First Article Detector Market is a specialized segment within the broader industrial automation and quality control industry. This market focuses on devices and systems designed to automate the process of first article inspection, which is a critical step in manufacturing. First article inspection involves verifying that a new or modified product meets all specified requirements before mass production begins. Fully automatic first article detectors streamline this process by using advanced technologies such as machine vision, artificial intelligence, and robotics to perform inspections with minimal human intervention. These systems are capable of detecting defects, measuring dimensions, and ensuring compliance with design specifications quickly and accurately. The adoption of fully automatic first article detectors is driven by the need for increased efficiency, reduced human error, and faster time-to-market in various industries. As manufacturing processes become more complex and demand for high-quality products rises, the importance of these detectors continues to grow. They are particularly valuable in sectors where precision and reliability are paramount, such as electronics, automotive, and aerospace. By automating the inspection process, companies can achieve higher levels of quality assurance, reduce waste, and improve overall production efficiency.

Floor-Standing Type, Desktop Type in the Global Fully Automatic First Article Detector Market:

In the Global Fully Automatic First Article Detector Market, two prominent types of systems are the Floor-Standing Type and the Desktop Type. Each of these types serves distinct purposes and caters to different industrial needs, offering unique advantages and features. The Floor-Standing Type is typically larger and more robust, designed for high-volume production environments where space is not a constraint. These systems are often integrated into the production line, allowing for seamless inspection of first articles as they are produced. The floor-standing models are equipped with advanced sensors and cameras, capable of handling large and complex components. They are ideal for industries such as automotive and aerospace, where the parts being inspected are often sizable and require comprehensive analysis. The robust nature of these systems ensures that they can operate continuously, providing reliable and consistent inspection results. On the other hand, the Desktop Type is more compact and versatile, suitable for smaller production facilities or laboratories where space is limited. These systems are designed for ease of use and flexibility, allowing operators to quickly set up and inspect different types of components. Desktop models are often used in electronics manufacturing, where the parts are smaller and require high precision. Despite their smaller size, these systems are equipped with sophisticated technology that ensures accurate and detailed inspections. The portability of desktop systems makes them an attractive option for companies that need to perform inspections at multiple locations or require a system that can be easily reconfigured for different tasks. Both types of fully automatic first article detectors play a crucial role in enhancing quality control processes across various industries. By automating the inspection process, these systems help manufacturers reduce the risk of defects, improve product quality, and increase production efficiency. The choice between a floor-standing or desktop model depends on the specific needs of the manufacturer, including the size and complexity of the components being inspected, the available space, and the desired level of automation. As technology continues to advance, both types of systems are expected to become even more sophisticated, offering enhanced capabilities and greater integration with other manufacturing processes. This evolution will further solidify their importance in the global market, as companies strive to meet the growing demand for high-quality products in an increasingly competitive landscape.

Electronics, Automotive, Aerospace, Others in the Global Fully Automatic First Article Detector Market:

The Global Fully Automatic First Article Detector Market finds extensive usage across various industries, including electronics, automotive, aerospace, and others, each benefiting from the unique capabilities of these advanced inspection systems. In the electronics industry, fully automatic first article detectors are crucial for ensuring the quality and reliability of electronic components and assemblies. With the increasing complexity of electronic devices, these systems help manufacturers maintain high standards by detecting defects and verifying dimensions with precision. They are particularly valuable in the production of printed circuit boards (PCBs), where even minor defects can lead to significant performance issues. By automating the inspection process, electronics manufacturers can achieve faster production cycles and reduce the risk of costly recalls. In the automotive industry, these detectors play a vital role in maintaining the safety and performance of vehicles. Automotive components must meet stringent quality standards, and fully automatic first article detectors provide the accuracy and consistency needed to ensure compliance. These systems are used to inspect a wide range of parts, from engine components to interior fittings, helping manufacturers identify defects early in the production process. This not only improves product quality but also enhances the overall efficiency of the manufacturing process. The aerospace industry also relies heavily on fully automatic first article detectors due to the critical nature of its products. Aerospace components must adhere to the highest quality standards to ensure safety and reliability. These detectors are used to inspect complex parts such as turbine blades, fuselage sections, and avionics components, where precision is paramount. By automating the inspection process, aerospace manufacturers can reduce the risk of defects and ensure that their products meet the rigorous demands of the industry. Beyond these primary industries, fully automatic first article detectors are also used in other sectors such as medical devices, consumer goods, and industrial equipment. In the medical device industry, for example, these systems help ensure the safety and efficacy of products by providing accurate and reliable inspections. In consumer goods, they are used to maintain quality standards and enhance customer satisfaction. Across all these industries, the adoption of fully automatic first article detectors is driven by the need for improved quality control, increased efficiency, and reduced production costs. As manufacturing processes continue to evolve, the importance of these systems is expected to grow, making them an essential tool for companies seeking to remain competitive in the global market.

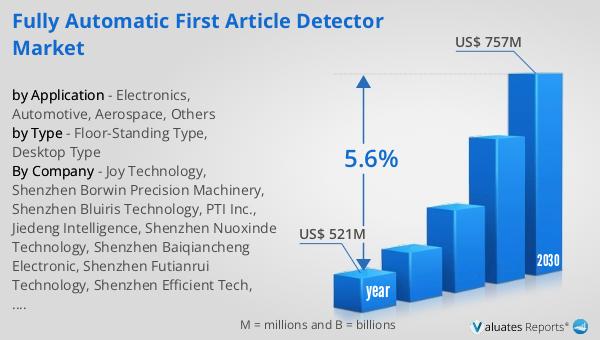

Global Fully Automatic First Article Detector Market Outlook:

The global market for Fully Automatic First Article Detectors was valued at approximately $521 million in 2023. It is anticipated to expand to a revised size of around $757 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.6% over the forecast period. This growth trajectory underscores the increasing demand for automated inspection solutions across various industries. The rise in market value can be attributed to several factors, including the growing complexity of manufacturing processes, the need for higher quality standards, and the push for greater efficiency in production lines. As industries continue to evolve and adopt more advanced technologies, the role of fully automatic first article detectors becomes increasingly critical. These systems offer significant advantages in terms of speed, accuracy, and reliability, making them an attractive investment for manufacturers looking to enhance their quality control processes. The projected growth in the market also highlights the expanding applications of these detectors in diverse sectors such as electronics, automotive, aerospace, and beyond. As companies strive to meet the demands of a competitive global market, the adoption of fully automatic first article detectors is expected to accelerate, driving further innovation and development in this field. This positive market outlook reflects the ongoing transformation of manufacturing industries and the pivotal role that automated inspection systems play in ensuring product quality and operational efficiency.

| Report Metric | Details |

| Report Name | Fully Automatic First Article Detector Market |

| Accounted market size in year | US$ 521 million |

| Forecasted market size in 2030 | US$ 757 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Joy Technology, Shenzhen Borwin Precision Machinery, Shenzhen Bluiris Technology, PTI Inc., Jiedeng Intelligence, Shenzhen Nuoxinde Technology, Shenzhen Baiqiancheng Electronic, Shenzhen Futianrui Technology, Shenzhen Efficient Tech, Shenzhen Shengdian Electronic Equipment, Liqian Intelligence, Fortune Tell |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |