What is Global Plywood Laser Cutting Machine Market?

The Global Plywood Laser Cutting Machine Market is a specialized segment within the broader laser cutting industry, focusing specifically on machines designed to cut plywood. Plywood, a versatile and widely used material, requires precise cutting techniques to meet the demands of various industries such as furniture manufacturing, construction, and automotive. Laser cutting machines offer a high level of precision and efficiency, making them ideal for cutting plywood into intricate shapes and designs. These machines use laser technology to vaporize the material along the desired cutting path, resulting in clean and accurate cuts. The market for plywood laser cutting machines is driven by the increasing demand for customized and high-quality plywood products. As industries continue to innovate and seek more efficient production methods, the adoption of laser cutting technology is expected to grow. The market is characterized by a range of machine types, including CO2 and fiber lasers, each offering unique advantages depending on the specific application and material requirements. Overall, the Global Plywood Laser Cutting Machine Market is poised for growth as industries recognize the benefits of laser cutting technology in enhancing production capabilities and product quality.

CO2 Laser, Fiber Laser in the Global Plywood Laser Cutting Machine Market:

CO2 and fiber lasers are two prominent types of laser technologies used in the Global Plywood Laser Cutting Machine Market, each offering distinct advantages and applications. CO2 lasers are one of the most common types of lasers used for cutting plywood. They operate by emitting a beam of infrared light, which is absorbed by the material, causing it to vaporize along the cutting path. CO2 lasers are known for their ability to cut a wide range of materials, including plywood, with high precision and speed. They are particularly effective for cutting non-metallic materials and are widely used in industries where intricate designs and smooth edges are required. The versatility of CO2 lasers makes them a popular choice for manufacturers looking to produce high-quality plywood products. On the other hand, fiber lasers represent a newer technology in the laser cutting industry. They use a solid-state laser source, which is more efficient and requires less maintenance compared to CO2 lasers. Fiber lasers are known for their high power density, which allows them to cut through materials quickly and with great precision. While they are more commonly used for cutting metals, advancements in technology have made them increasingly suitable for cutting plywood as well. Fiber lasers offer several advantages, including lower operating costs, reduced energy consumption, and a longer lifespan. These benefits make them an attractive option for manufacturers looking to optimize their production processes. In the context of the Global Plywood Laser Cutting Machine Market, both CO2 and fiber lasers play a crucial role in meeting the diverse needs of industries that rely on plywood products. The choice between CO2 and fiber lasers often depends on the specific requirements of the application, such as the thickness of the plywood, the desired cutting speed, and the level of precision needed. As technology continues to evolve, the capabilities of both CO2 and fiber lasers are expected to improve, further enhancing their suitability for cutting plywood. Manufacturers in the market are continually exploring new ways to leverage these technologies to improve efficiency, reduce costs, and deliver high-quality products to their customers. Overall, the Global Plywood Laser Cutting Machine Market benefits from the advancements in both CO2 and fiber laser technologies, providing industries with the tools they need to meet the growing demand for precision-cut plywood products.

Furniture Manufacturing, Construction, Automobile Manufacturing, Others in the Global Plywood Laser Cutting Machine Market:

The Global Plywood Laser Cutting Machine Market finds extensive usage across various industries, including furniture manufacturing, construction, automobile manufacturing, and others. In the furniture manufacturing industry, plywood laser cutting machines are used to create intricate designs and patterns on furniture pieces. The precision and accuracy of laser cutting technology allow manufacturers to produce high-quality furniture with complex shapes and detailed engravings. This capability is particularly valuable in the production of custom furniture, where unique designs and specifications are required. Laser cutting machines also enable manufacturers to optimize material usage, reducing waste and lowering production costs. In the construction industry, plywood laser cutting machines are used to produce components for building structures, such as wall panels, flooring, and roofing materials. The ability to cut plywood with precision ensures that components fit together seamlessly, improving the overall quality and durability of the construction. Laser cutting technology also allows for the production of complex architectural designs, enabling architects and builders to create innovative and aesthetically pleasing structures. In the automobile manufacturing industry, plywood laser cutting machines are used to produce interior components, such as dashboards, door panels, and trim pieces. The precision of laser cutting technology ensures that these components meet the exact specifications required for vehicle assembly. Additionally, laser cutting machines enable manufacturers to produce lightweight components, contributing to the overall efficiency and performance of the vehicle. Beyond these industries, plywood laser cutting machines are also used in various other applications, such as signage, packaging, and model making. The versatility of laser cutting technology allows it to be adapted for a wide range of uses, making it an essential tool for industries that rely on plywood products. As the demand for high-quality, precision-cut plywood continues to grow, the Global Plywood Laser Cutting Machine Market is expected to expand, providing industries with the tools they need to meet the evolving needs of their customers.

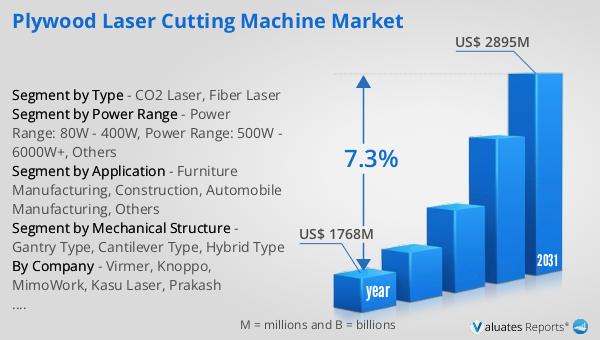

Global Plywood Laser Cutting Machine Market Outlook:

The global market for Plywood Laser Cutting Machines was valued at $1,768 million in 2024, and it is anticipated to grow significantly, reaching an estimated value of $2,895 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.3% over the forecast period. This upward trend is indicative of the increasing demand for precision cutting technologies across various industries that utilize plywood. The market's expansion can be attributed to several factors, including advancements in laser cutting technology, the growing need for customized plywood products, and the efficiency and precision offered by laser cutting machines. As industries such as furniture manufacturing, construction, and automotive continue to evolve, the demand for high-quality, precision-cut plywood components is expected to rise. This, in turn, drives the adoption of laser cutting machines, which offer the accuracy and efficiency needed to meet these demands. Additionally, the market's growth is supported by the increasing awareness of the benefits of laser cutting technology, such as reduced material waste, lower production costs, and the ability to produce complex designs with ease. As a result, more manufacturers are investing in laser cutting machines to enhance their production capabilities and remain competitive in the market. Overall, the Global Plywood Laser Cutting Machine Market is poised for significant growth, driven by the increasing demand for precision-cut plywood products and the continued advancements in laser cutting technology.

| Report Metric | Details |

| Report Name | Plywood Laser Cutting Machine Market |

| Accounted market size in year | US$ 1768 million |

| Forecasted market size in 2031 | US$ 2895 million |

| CAGR | 7.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Mechanical Structure |

|

| Segment by Power Range |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Virmer, Knoppo, MimoWork, Kasu Laser, Prakash Industries, ADEWO, AccTek Laser, Kern Laser Systems, HITEC CNC, Unitek Laser, Epilog Laser, KAIXUAN, Trotec Laser, Baison Laser, Han's Laser Technology Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |